An organic electroluminescent device with improved working life and manufacturing method thereof

An electroluminescence device and a technology of a manufacturing method, applied in the direction of electroluminescence light source, electric light source, lighting device, etc., can solve the problem that the service life of the organic light-emitting device 10 cannot be effectively improved, and the drainage treatment effect and efficiency of the color filter 11 problems such as inability to manifest

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

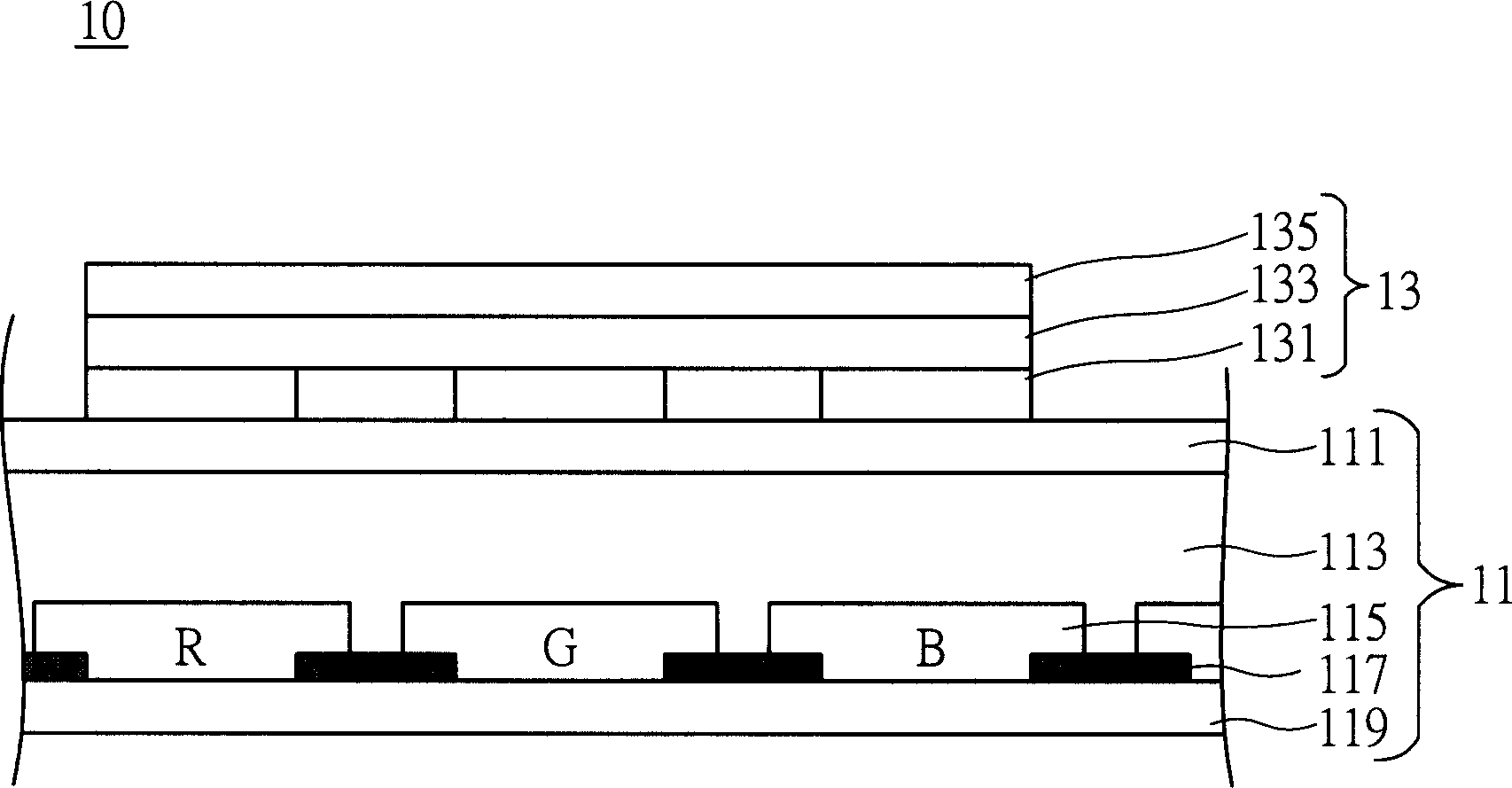

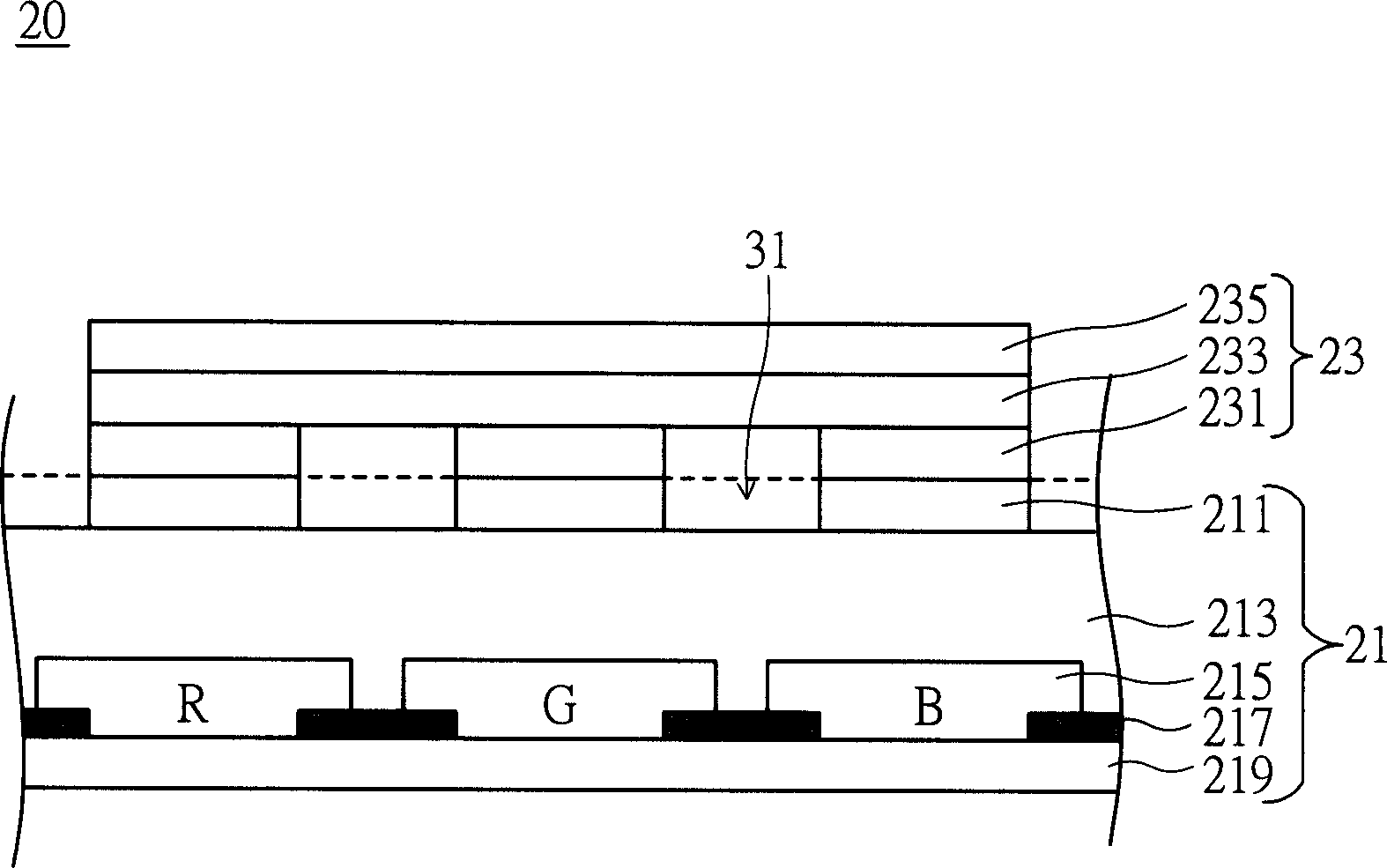

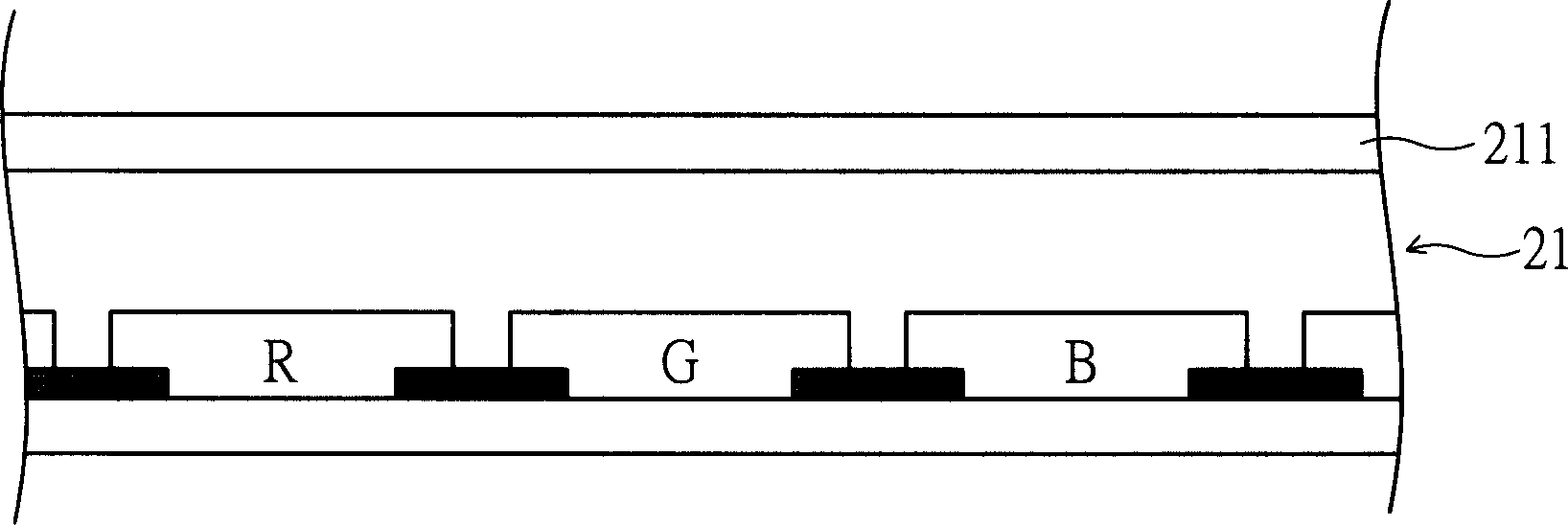

[0033] First, see figure 2 It is a schematic cross-sectional view of a preferred embodiment of the present invention; as shown in the figure, the organic electroluminescent device 20 of the present invention that can improve the service life is mainly provided with at least one organic electroluminescent device above a color filter 21 (ColorFilter). Lighting component 23. Wherein, the structure of the color filter 21 is provided with at least one black matrix 217 (Black Matrix) on the upper surface of a transparent substrate 219, and at least one color matrix is provided on the upper surface of the transparent substrate 219 without black matrix 217. Photoresist 215 to achieve the purpose of light color conversion. Also, above the black matrix 217 and the color photoresist 215, a coating layer 213 (over coat) and a light-transmitting isolation layer 211, such as a silicon dioxide layer, a silicon nitride layer or a silicon oxynitride compound, are sequentially provided. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com