Low temperature sanitization of human pathogens from the surfaces of food and food packaging

A technology for pathogens and food, applied in the field of killing microorganisms on food, can solve the problem that the processing technology is not suitable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

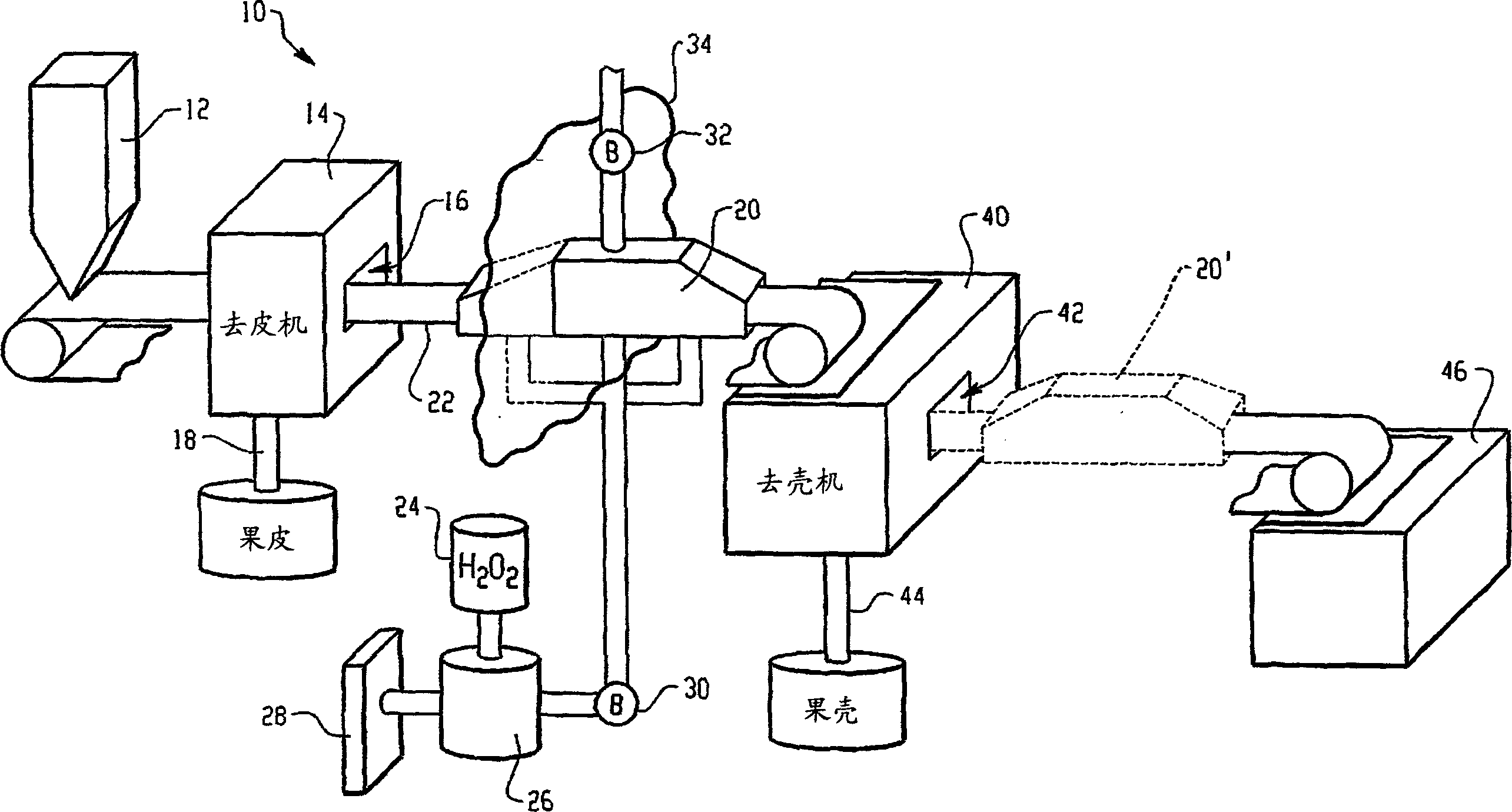

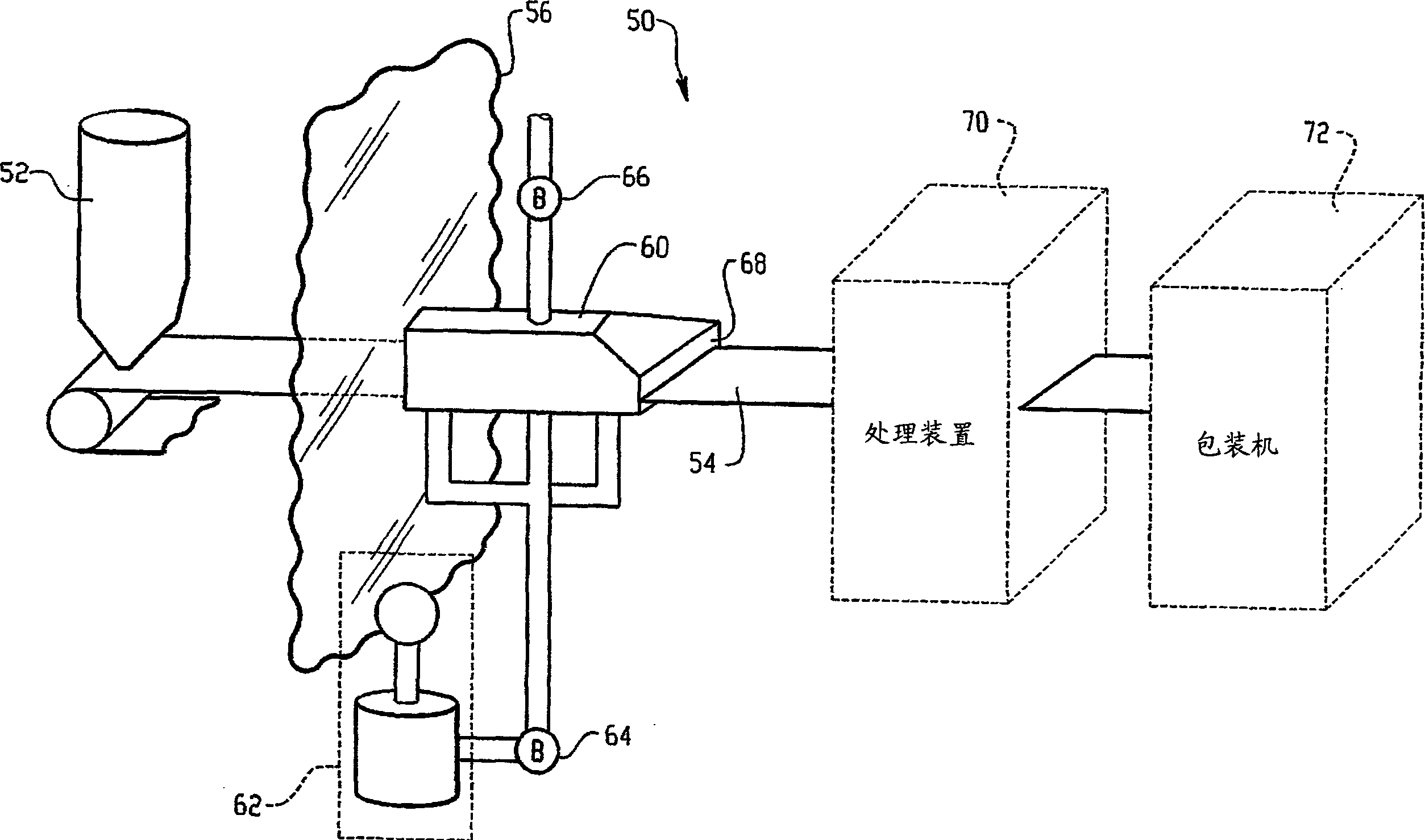

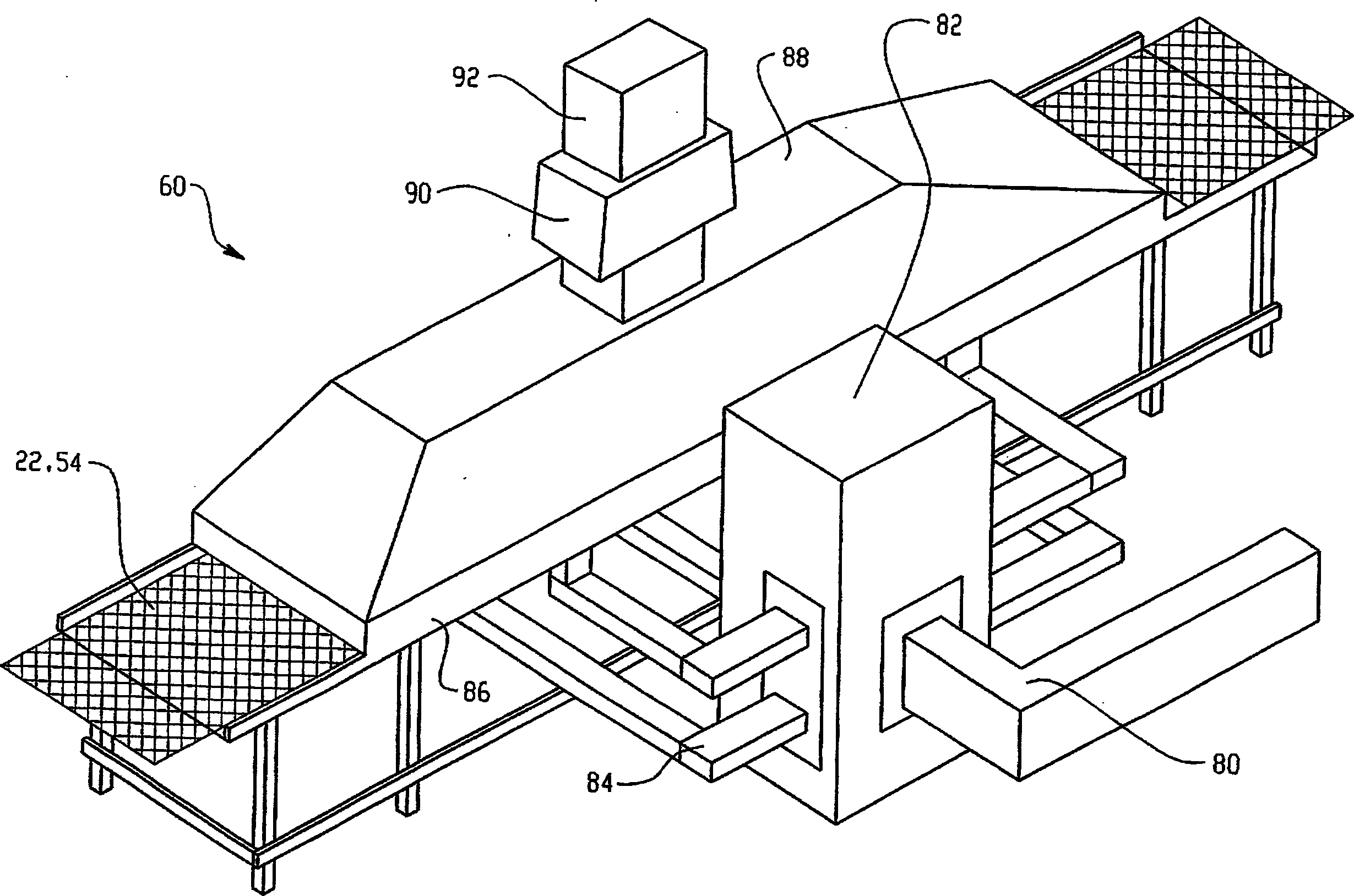

[0022] At harvest time, almonds or other shelled foods are collected in large quantities in the peeling and shelling device 10 . A quantity of almonds is poured into a larger hopper or other feeder 12 from which the almonds or other food product is fed to a peeler 14 . The peeler discharges the shelled almonds at one outlet 16 and the peels through a second outlet 18 . The peels exit the unit and are used for other agricultural purposes, such as an additive to livestock feed. The shelled almonds are conveyed from the outlet 16 to the first sterilization chamber 20 on a perforated mesh conveyor belt 22 .

[0023] The sterilization chamber 20 exposes the shelled almonds to a gaseous oxidant, such as ozone, liquid oxidant vapor, concentrated oxidant, plasma, or the like and combinations thereof. In a preferred embodiment, the gaseous oxidant is air at a hydrogen peroxide vapor concentration of about 1.8 mg / L or greater. More particularly, in the preferred embodiment, liquid hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com