Device and method for eliminating SO2 from gas with combined ultrasonic wave and hollow fiber containing soaked film

A technology for sulfur dioxide and gas removal, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of decreased absorption, poor mass transfer effect, poor absorption efficiency, etc. Quality efficiency and the effect of reducing the amount of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

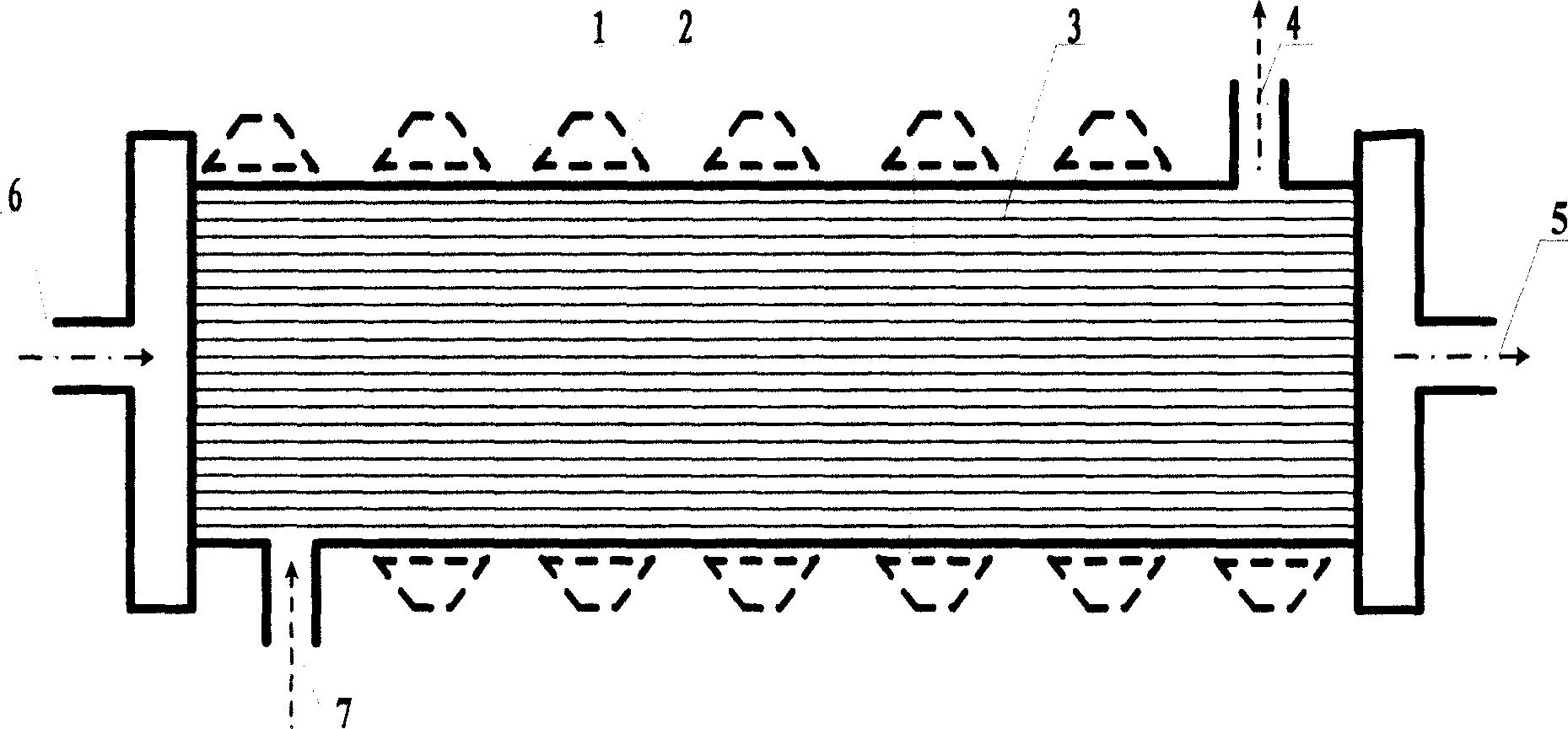

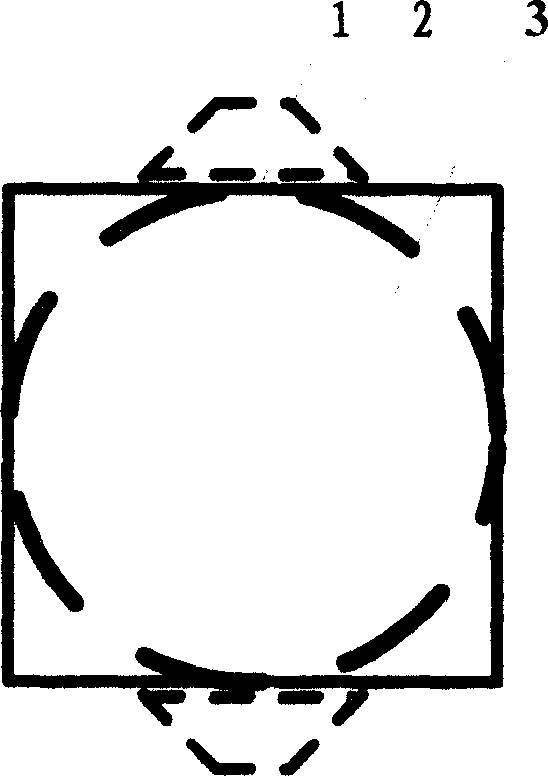

[0024] As shown in the figure, add 0.60M citrate solution from the liquid inlet (7) into the shell side of the hollow fiber membrane module (3), and the gas with a sulfur dioxide content of 5000ppm enters the hollow fiber membrane through the gas inlet (6) In the tube side of component (3); under the action of 20KHz ultrasonic waves, the absorption temperature is 25°C, and the unit ultrasonic power of the absorption liquid is 50W, the concentration of sulfur dioxide in the gas can be kept below 5ppm within 10-200 hours; the absorbed citric acid The salt solution is used for the production and cyclic absorption of high-concentration sulfur dioxide; the treated gas is discharged from the gas outlet (5), and the treated citrate solution is discharged from the liquid outlet (4) to produce high-concentration sulfur dioxide and cyclic reabsorption .

Embodiment 2

[0026] Solution concentration, liquid film formation process and gas-liquid exchange mode are basically the same as Example 1.

[0027] Under the action of 40KHz ultrasonic waves, the absorption temperature is 25°C, and the unit ultrasonic power of the absorption liquid is 40W, the concentration of sulfur dioxide in the gas can be kept below 10ppm within 5-150 hours; the absorbed citrate solution is used for the production of high-concentration sulfur dioxide and cyclic absorption.

Embodiment 3

[0029] Solution concentration, liquid film formation process and gas-liquid exchange mode are basically the same as Example 1.

[0030] Under the action of 60KHz ultrasonic waves, the absorption temperature is 25°C, and the unit ultrasonic power of the absorption liquid is 60W, the concentration of sulfur dioxide in the gas can be kept below 20ppm within 10-300 hours; the absorbed citrate solution is used for the production of high-concentration sulfur dioxide and cyclic absorption.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com