Automatic compression release mechanism

A mechanical device and automatic technology, applied in the direction of valve device, mechanical equipment, engine components, etc., can solve problems such as fragile, variable weight shaft holding force, and long shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

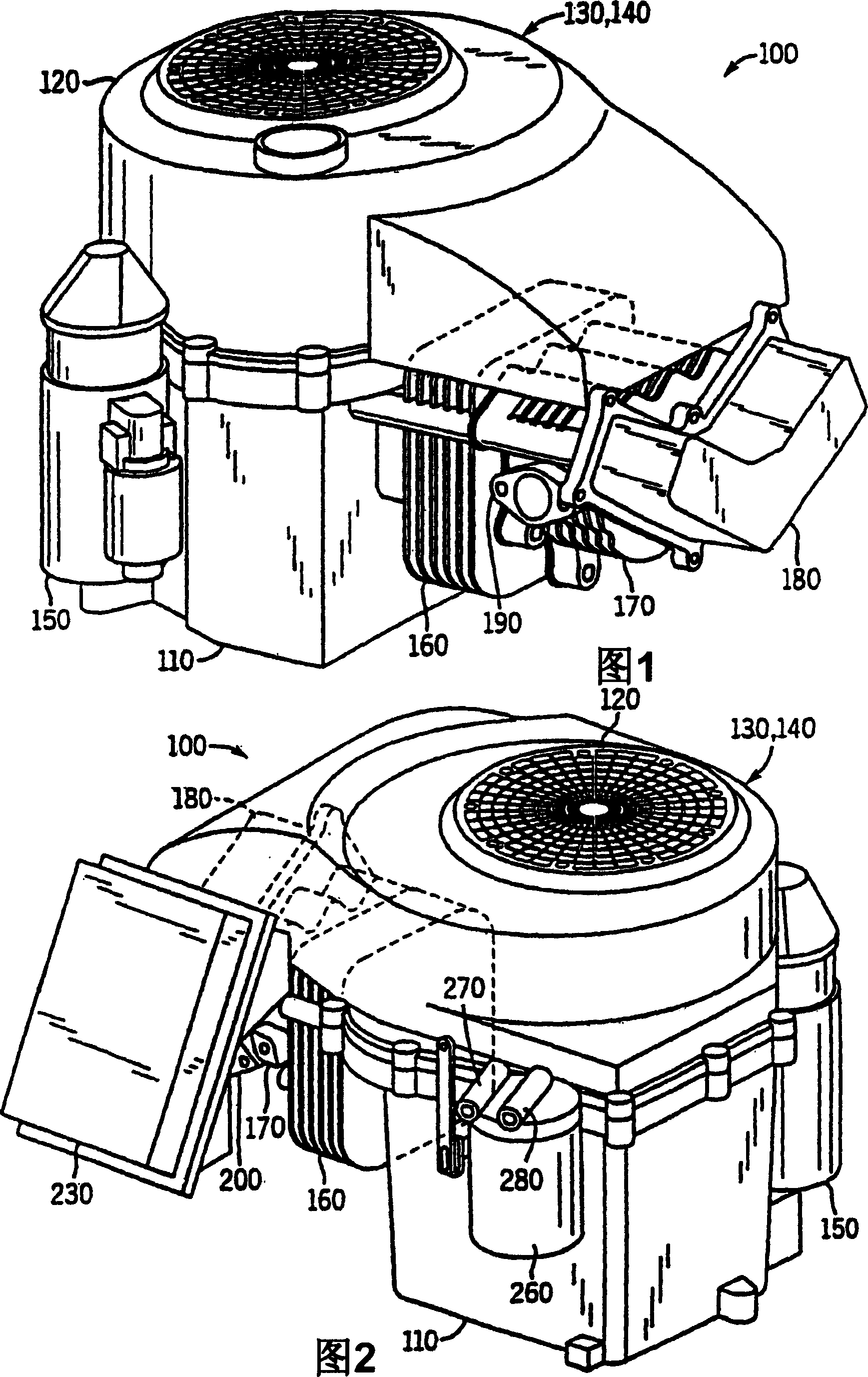

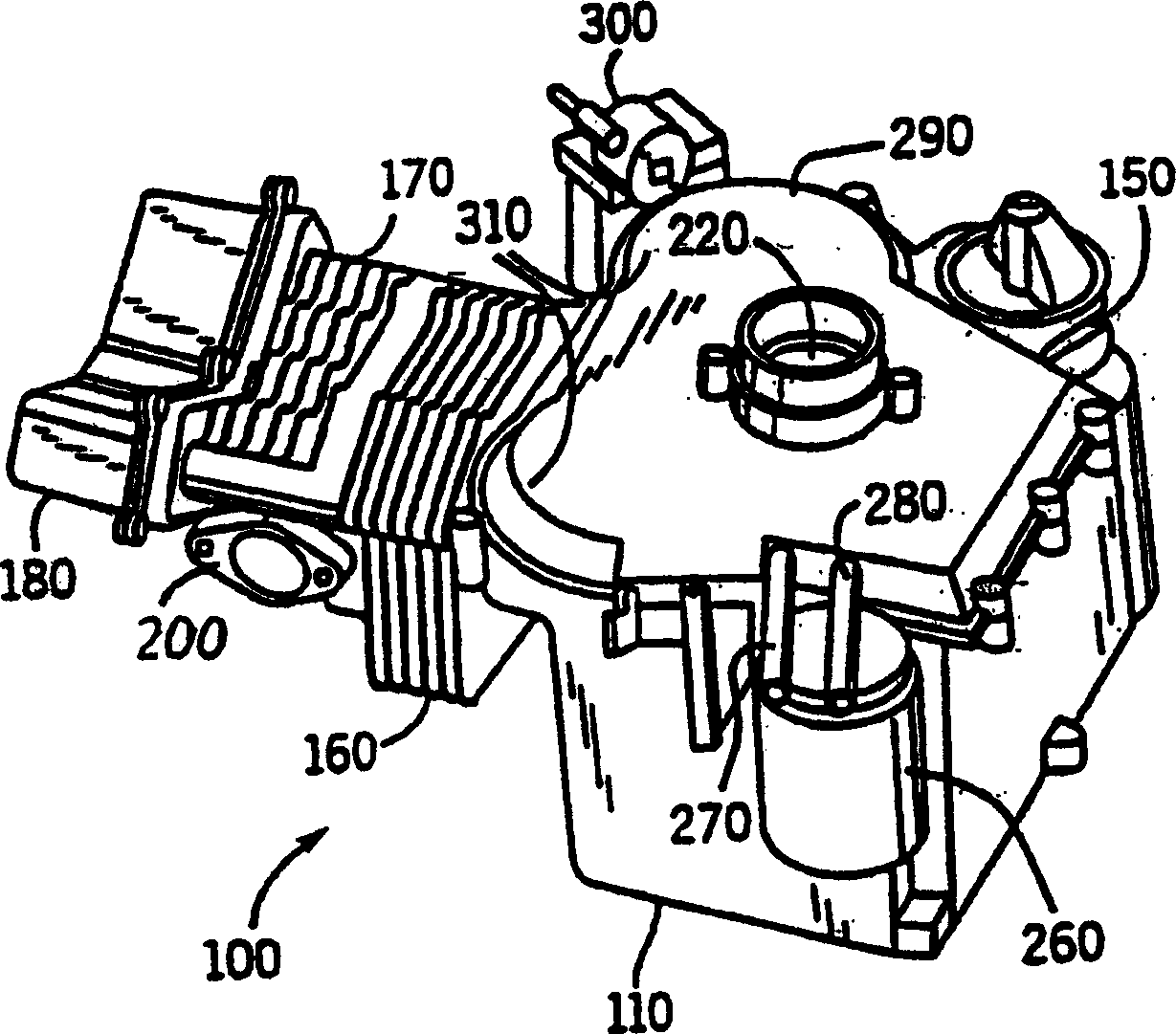

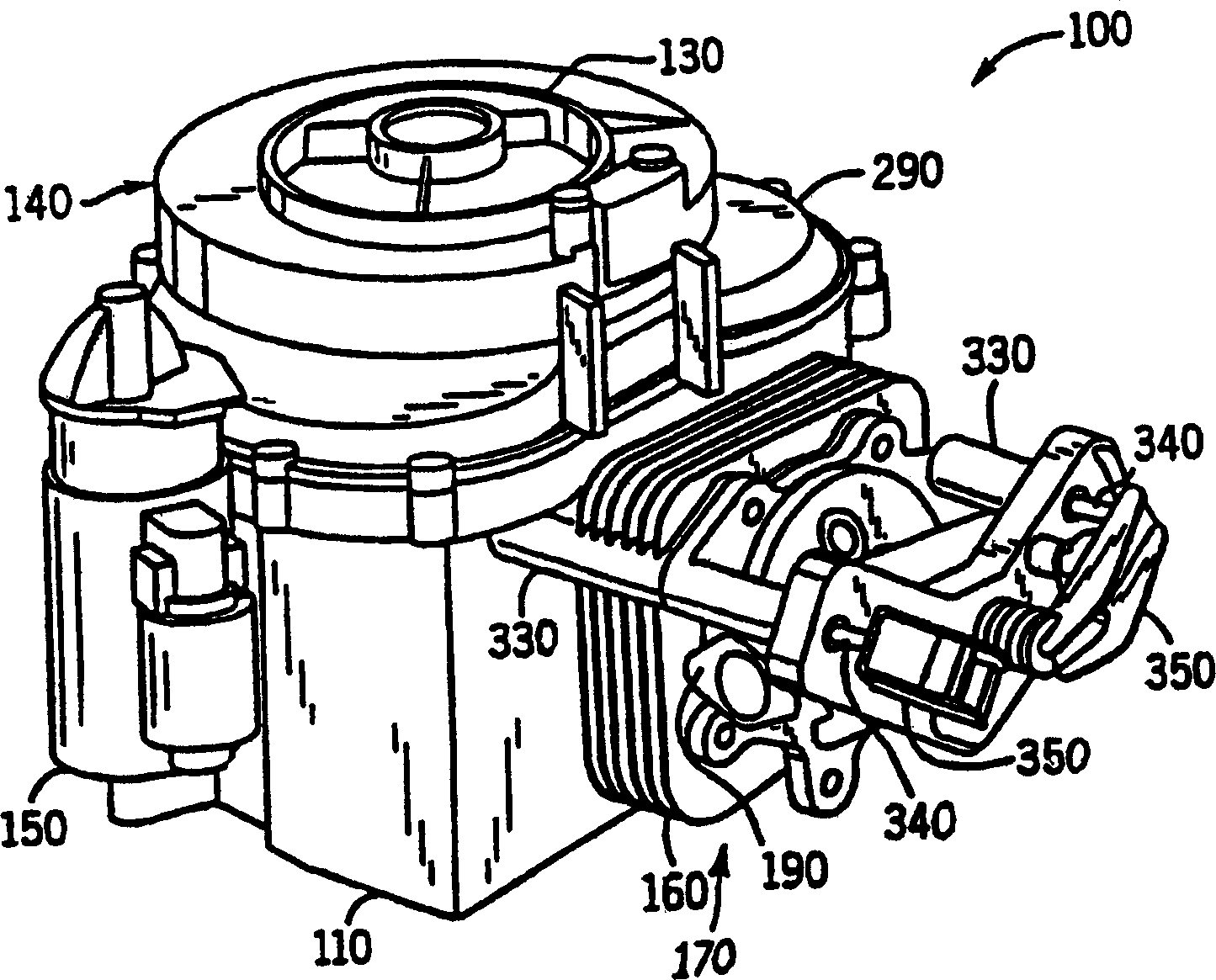

[0021] 1 and 2, a new type of single-cylinder, 4-stroke engine 100 designed by Kohler Corporation of Kohler, Wisconsin includes a crankcase 110 and a blower housing 120. Inside the blower housing 120, there are a fan 130 and a flywheel 140. The engine 100 also includes a starter 150, a cylinder 160, a cylinder head 170, and a rocker cover 180. On the cylinder head 170 are the exhaust port 190 shown in FIG. 1 and the intake port 200 shown in FIG. 2. As known in the art, during the operation of the engine 100, the piston 210 (see FIG. 7) moves back and forth in the cylinder 160 toward and away from the cylinder head 170. The movement of the piston 210 in turn causes the rotation of the crankshaft 220 (see FIG. 7), and the rotation of the fan 130 and the flywheel 140 connected to the crankshaft. The rotation of the fan 130 cools the internal combustion engine, while the rotation of the flywheel 140 causes a relatively constant rotational momentum to be maintained.

[0022] Referring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com