Method of microelectrode connection and connected structure of use thereof

A technology for connecting structures and electrodes, applied in circuits, electrical components, printed circuits, etc., to solve problems such as interconnection, electrode short-circuit, and circuit board failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

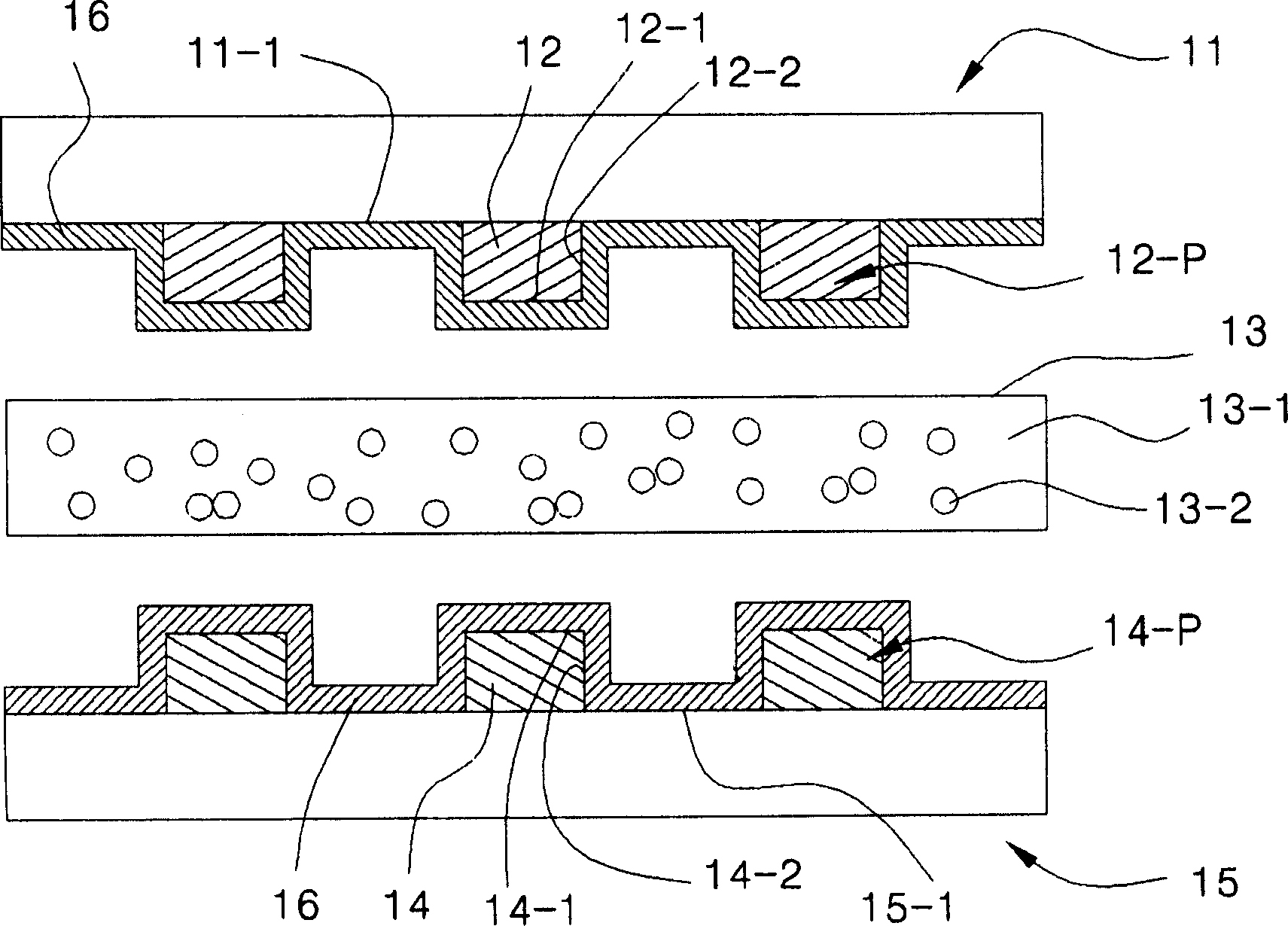

[0055] Polyester resin (Toyobo Co., Vylon200 TM ) is dissolved in a mixed solvent in which ketone and toluene are mixed in a weight ratio of 3:1 to prepare a solution with a solid content of 25%. Next, the resin solution was applied to the electrode portion of TCP having a line width of 30 μm, a pitch of 60 μm, and a thickness of 18 μm using a screen printer. Then, the TCP coated with the resin solution was dried in an oven at 70° C. by hot air for 5 minutes, so as to obtain the TCP coated with the insulating film. Thereafter, the thickness of the insulating film was measured to be 1 μm using a micrometer.

Embodiment 2

[0057] Adopt the same method as embodiment 1 to prepare the TCP that is coated with insulating film, difference is: vinyl acetate resin (Okong bond Co., PVAc302 TM ) was dissolved in a mixed solvent of methyl ethyl ketone and toluene mixed at a weight ratio of 3:1 to prepare a solution with a solid content of 25%. Then, a TCP coated with an insulating film having a thickness of 1 μm was produced by the method of Example 1.

Embodiment 3

[0059] Adopt the same method as embodiment 1 to prepare the TCP that is coated with insulating film, difference is: the nitro polybutadiene rubber (Nippon zeon Co., Nippol FN4002 TM ) was dissolved in a mixed solvent mixed with methyl ethyl ketone and toluene at a weight ratio of 3:1 to prepare a solution with a solid content of 25%. Then, by the method of Example 1, a TCP coated with an insulating film having a thickness of 1 µm was produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com