Rotary dual-cylinder compressor using exhaust middle partition board

A dual-cylinder compressor, rotary technology, applied in the field of compressors, can solve the problems of large exhaust resistance of the compressor, no exhaust function, design of exhaust ports, etc., to reduce exhaust resistance, smooth exhaust, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

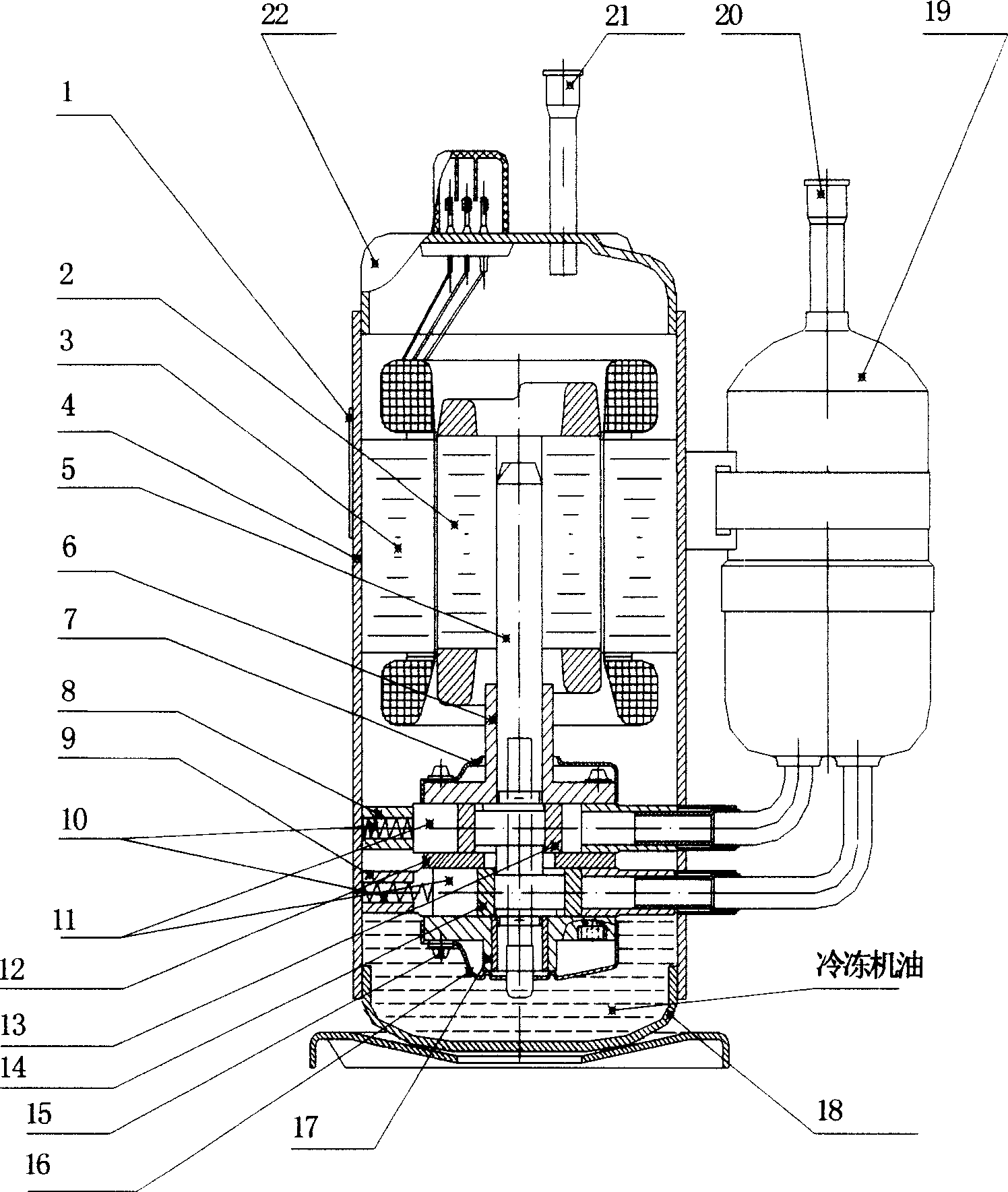

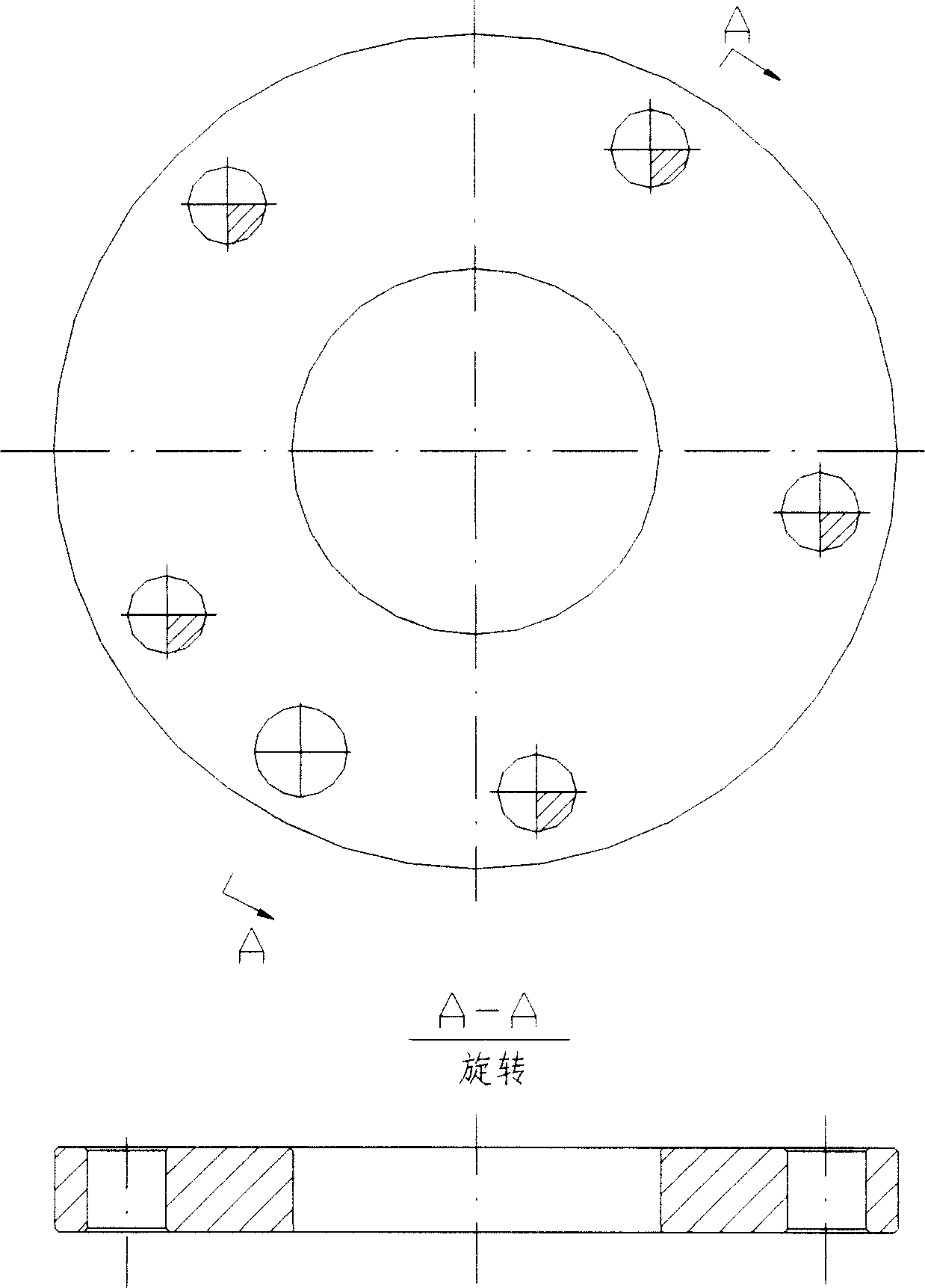

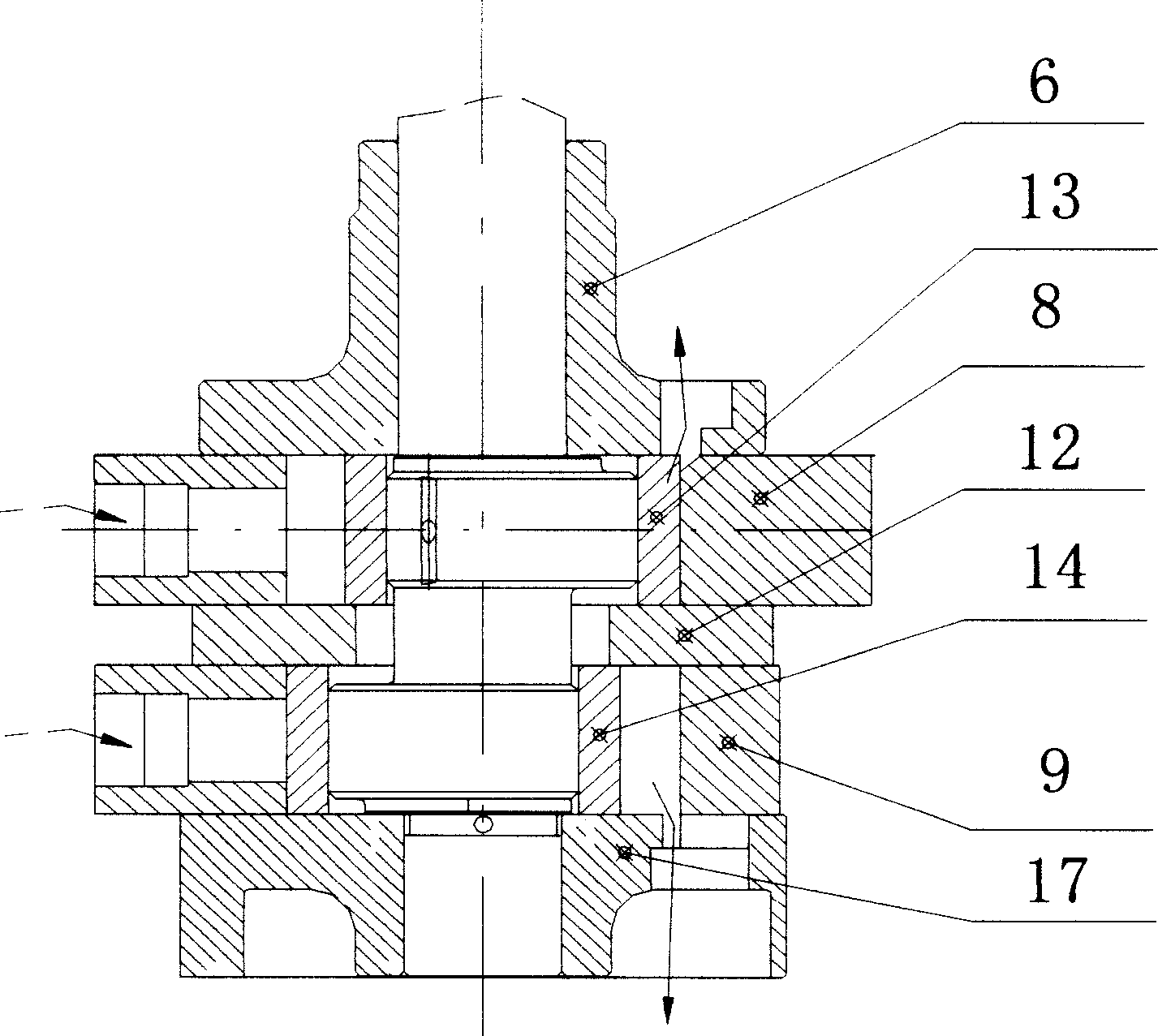

[0023] exist Figure 4 In the first embodiment shown, the rotary double-cylinder compressor consists of a motor composed of a motor rotor (2), a motor stator (3), an eccentric shaft (5), an upper cover (6), an upper muffler cover (7), an upper Cylinder (8), lower cylinder (9), upper rotor (13), lower rotor (14), lower muffler cover (16), lower cover (17), upper partition (24), lower partition (23), etc. The pump body that forms is installed in a sealed container that is made up of cylinder body (4), lower outer cover (18), upper outer cover (22), deposits refrigerating machine oil at the bottom of sealed container. The whole compressor is connected with other parts of the air conditioning system through the intake pipe (20) and the exhaust pipe (21), and the liquid storage cylinder (19) plays the role of air suction and gas-liquid separation. Figure 5 It is a structure of one partition (lower partition or upper partition) in the separated double-piece middle partition with e...

no. 2 example

[0028] exist Figure 7 In the second embodiment shown, the rotary double-cylinder compressor consists of a motor composed of a motor rotor (2), a motor stator (3), an eccentric shaft (5), an upper cover (6), an upper muffler cover (7), an upper Cylinder (8), lower cylinder (9), upper rotor (13), lower rotor (14), lower muffler cover (16), lower cover (17), upper partition (24), auxiliary partition (27), etc. The pump body that forms is installed in a sealed container that is made up of cylinder body (4), lower outer cover (18), upper outer cover (22), deposits refrigerating machine oil at the bottom of sealed container. The whole compressor is connected with other parts of the air conditioning system through the intake pipe (20) and the exhaust pipe (21), and the liquid storage cylinder (19) plays the role of air suction and gas-liquid separation. The upper dividing plate (24) is provided with an exhaust port (25) and a valve seat groove (26) for installing parts such as an e...

no. 3 example

[0031] exist Figure 9 In the third embodiment shown, the rotary double-cylinder compressor consists of a motor composed of a motor rotor (2), a motor stator (3), an eccentric shaft (5), an upper cover (6), an upper muffler cover (7), an upper Cylinder (8), lower cylinder (9), upper rotor (13), lower rotor (14), lower muffler cover (16), lower cover (17), lower partition (23), auxiliary partition (27), etc. The pump body that forms is installed in a sealed container that is made up of cylinder body (4), lower outer cover (18), upper outer cover (22), deposits refrigerating machine oil at the bottom of sealed container. The whole compressor is connected with other parts of the air conditioning system through the intake pipe (20) and the exhaust pipe (21), and the liquid storage cylinder (19) plays the role of air suction and gas-liquid separation. The lower dividing plate (23) is provided with an exhaust port (25) and a valve seat groove (26) for installing parts such as an ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com