Dual site catalyst system comprising a hafnocene component for the production of bimodal polyolefins in a single reactor

A metallocene catalyst, polyolefin technology, applied in the field of catalyst systems, can solve the problems of low activity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

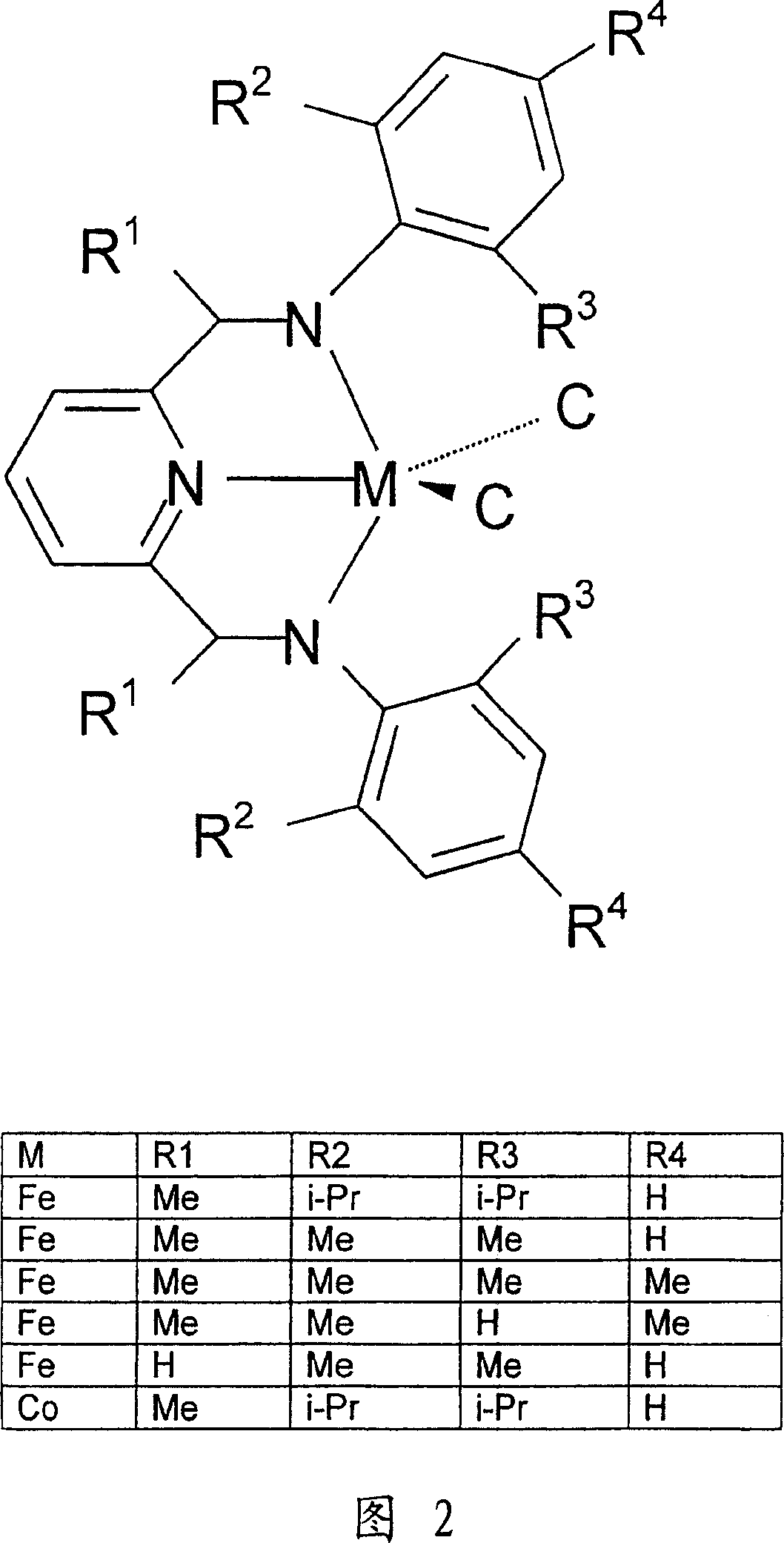

[0021] The hafnium-based metallocene component of the present invention has the following formula structure:

[0022] R” s (CpR n ) g (CpR n )MQ 3-g (I)

[0023] in

[0024] - each Cp is a substituted or unsubstituted cyclopentadienyl ring;

[0025] - each R may be the same or different and is a hydrogen or hydrocarbyl group, such as an alkyl, alkenyl, aryl, alkylaryl or aralkyl group or two carbon atoms containing 1 to 20 carbon atoms connected to form a C4-C6 ring;

[0026] -R" is a structural bridge between two Cp rings;

[0027] -M is hafnium;

[0028] -Q is a hydrocarbyl group such as an aryl, alkyl, alkenyl, alkylaryl or aralkyl group containing 1-20 carbon atoms, a hydrocarboxy group or halogen containing 1-20 carbon atoms , and they can be the same or different from each other;

[0029] -s is 0 or 1, g is 0, 1 or 2, and when g is 0, s is 0, when s is 1, n is 4, and when s is 0, n is 5.

[0030] By substitution, it means that the substituent which replaces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com