Application of rare earth magnetic expansion material on bandset vibration mechanism

A technology of giant magnetostriction and vibration mechanism, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, fluids using vibration, etc., can solve the impact of product consistency and qualification rate, Difficult to achieve and other problems, to achieve the effect of simplifying the design and processing technology of the whole machine, improving performance indicators, and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

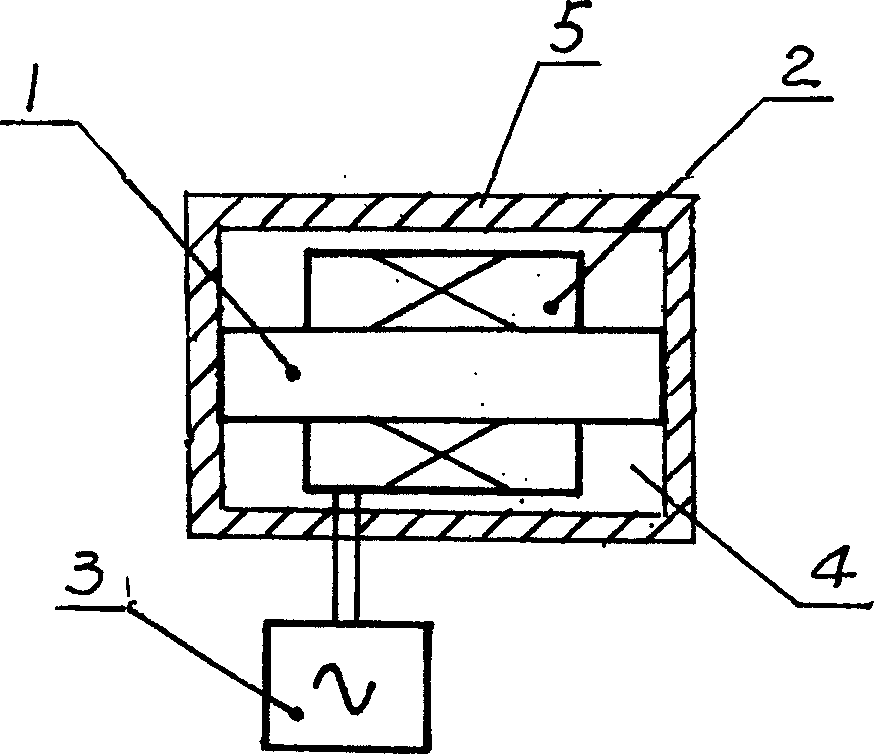

[0021] Example 1: from figure 1 It can be clearly seen that the mobile phone vibrating mechanism of the present invention is composed of a vibrating element 1 made of rare earth giant magnetostrictive material, a driving coil 2, an alternating circuit 3 and a housing 5 provided with a vibrating element installation cavity 4. The vibrating element 1 is a rare-earth giant magnetostrictive material bar with a diameter of 1-2 mm and a length of 8-10 mm. The externally wound drive coil 2 is composed of enameled wire with turns; the two ends of the drive coil 2 are connected to the The alternating circuit 3 is connected; the vibrating element 1 wound with the driving coil 2 is arranged in the vibrating element installation cavity 4 , and the two ends of the vibrating element 1 are closely matched with the walls of the vibrating element installation cavity 4 .

[0022] The working process is: the vibration mechanism of the mobile phone is directly clamped in the mobile phone shell, a...

Embodiment 2

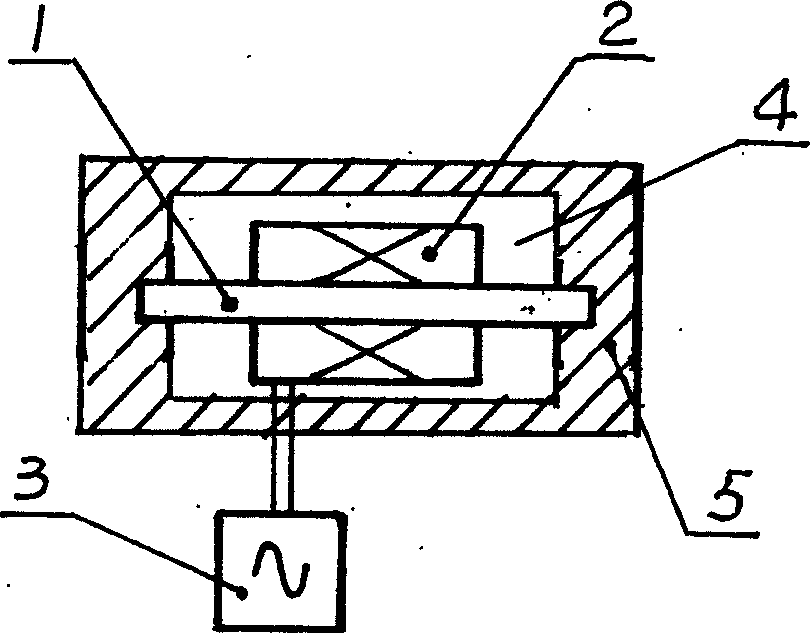

[0024] Example 2: From figure 2 It can be clearly seen that the basic structure of this embodiment is the same as that of Embodiment 1, and the difference is: in order to adapt to the development trend of thinner and thinner mobile phones, the rare earth giant magnetostrictive material is made into a sheet-shaped vibrating element 1, and its size It is 2×5×1mm, that is, its thickness is only 1mm, the vibrating part 1 is very small, and the driving coil 2 can be conventionally wound, or it can adopt a bodiless, sheet structure, and the formed vibration mechanism is as flat as paper, which can maximize Minimize the casing of the vibrator installation cavity. Its working process is identical with embodiment 1.

Embodiment 3

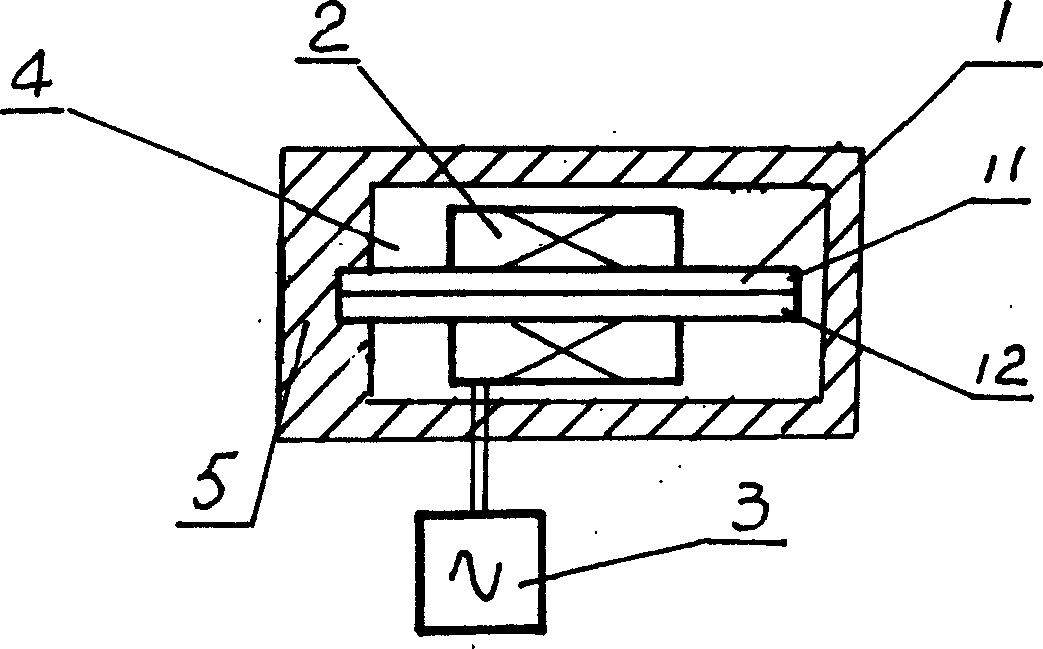

[0025] Example 3: from image 3 It can be clearly seen that the basic structure of this embodiment is the same as that of Embodiment 1, and the difference is that the vibrating element 1 is a double-laminated structure, that is, it is made of two rare earth giant magnetostrictive material sheets 11 and 12 of the same size and performance. combined. The vibrating mechanism made of the vibrating element 1 with the double lamination structure can effectively reduce the dynamic loss of the material and improve the dynamic response characteristic.

[0026] If the magnetostrictive coefficients of the two rare earth giant magnetostrictive material sheets 11 and 12 selected for use are different; At the same time, a cantilever beam structure is adopted, that is, one end is fixed and the other end is suspended. At this time, when the driving coil is supplied with an alternating current, the laminations will generate bending vibration to change the original vibration perpendicular to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com