Electric tool safety special spanner

An electric tool and safe technology, applied in the direction of wrenches, manufacturing tools, screwdrivers, etc., can solve the problems of inability to install or disassemble with screws and nuts, inconvenient to install and disassemble with electric tools, and inconvenient to operate, and achieve novel structure and reliable performance. , the effect of simple appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

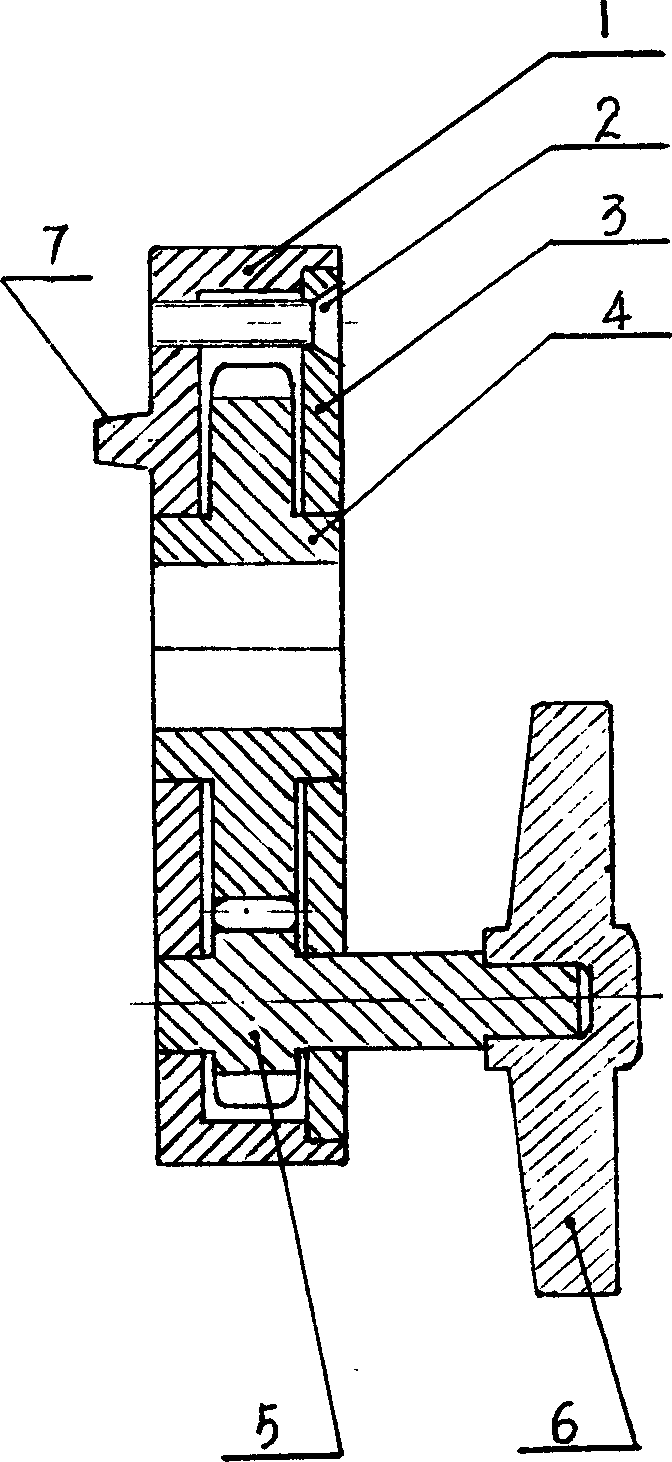

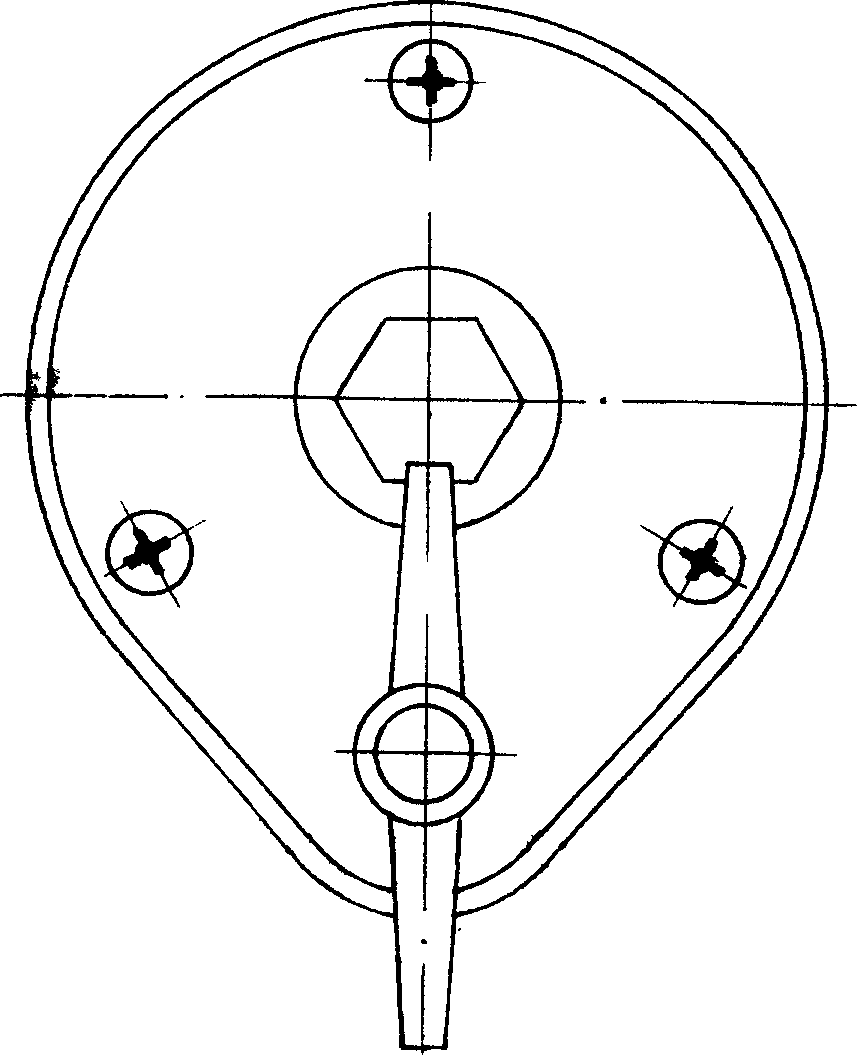

[0011] Embodiment 1: with reference to attached figure 1 and 2 . Special wrench for electric tool safety, the positioning loading and unloading surface of the housing 1 is provided with an eccentricity support point 7 and a wrench head 4 (the 4 here refers to the wrench head in the wrench head gear), which are located in the gear sets 4 and 5 in the housing The power output shaft drives the wrench to rotate, and the gear set constitutes an offset transmission torsion structure, and the power input gear 5 in the gear set is connected with the power input shaft and driven by the power input shaft to rotate. The positioning support point 7 is a boss or a groove and has an integral structure or a split connection structure with the shell 1 surface; the wrench head 4 is a socket wrench head or a convex wrench head, and the socket wrench head and the convex wrench head are internal and external. Multi-deformed inner hexagonal or inner square or inner triangle (see the common hardw...

Embodiment 2

[0012] Embodiment 2: On the basis of Embodiment 1, the end of the wrench head 4 is a through hole, and magnets 16 are placed around the through hole at the end of the wrench head. Figure 4 .

Embodiment 3

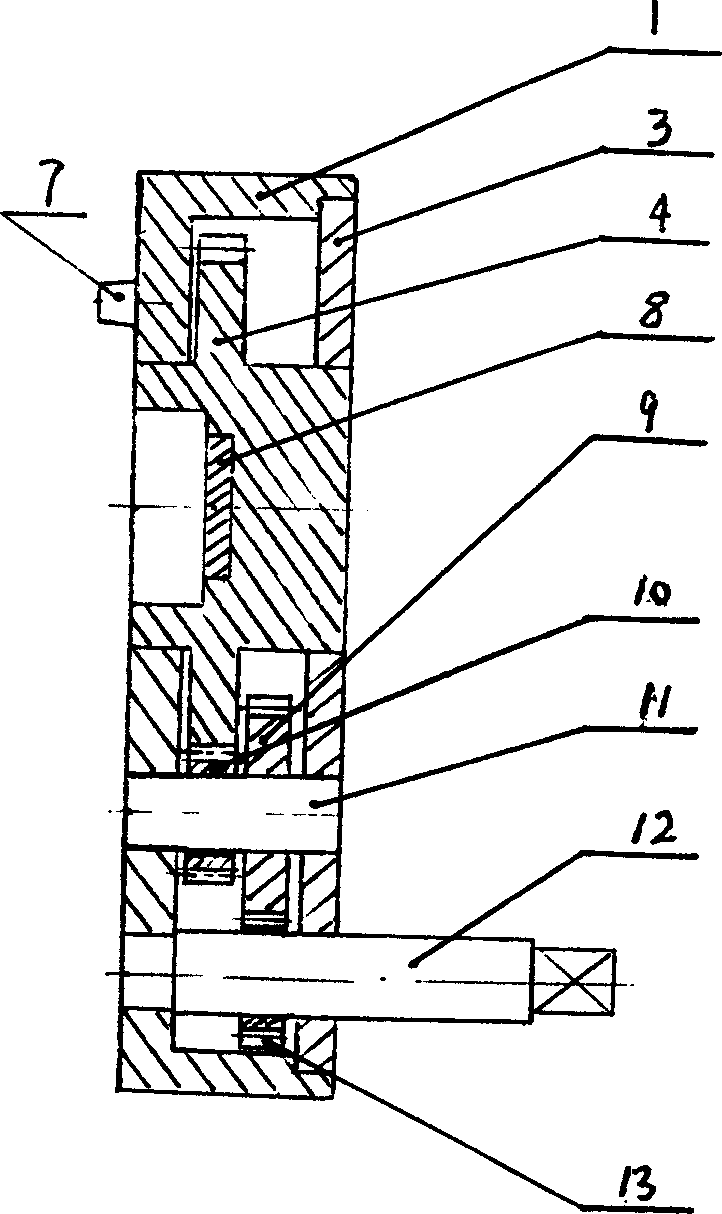

[0013] Embodiment 3: with reference to attached image 3 . On the basis of Embodiment 1, the gear set consists of the wrench head shaft power output gear 4 (also known as the wrench head gear, that is to say, the wrench gear is composed of the wrench head and the gear, and the outer diameter of the wrench head is the gear shaft), The first-stage bridge gear 9 and 10 and shaft power input gear 13 are composed of the input shaft 12 to drive the input gear 13 to rotate, the input gear 13 meshes with the large gear 9 in the bridge gear, the pinion gear 10 in the bridge gear and the wrench head The gear meshes and drives the wrench head gear to rotate, and the bridge gear is composed of the bridge gear 9 and the bridge pinion 10 and under the effect of the shaft 11, the two rotate synchronously. The wrench head gear is formed integral structure by gear and wrench head or is formed integral structure by split, and the technology that forms is prior art, does not narrate at this; Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com