Method of artificial board production line thermopress loading and unloading and machine set

A production line and wood-based panel technology, applied to household components, flat products, household appliances, etc., can solve problems such as high energy consumption, production stoppage, and damage to equipment, and achieve the effect of increasing the number of layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A specific embodiment of the present invention is applied to a hot-press loading and unloading unit of a wood-based panel production line that produces 6*18 feet and an annual output of 100,000 cubic meters of MDF.

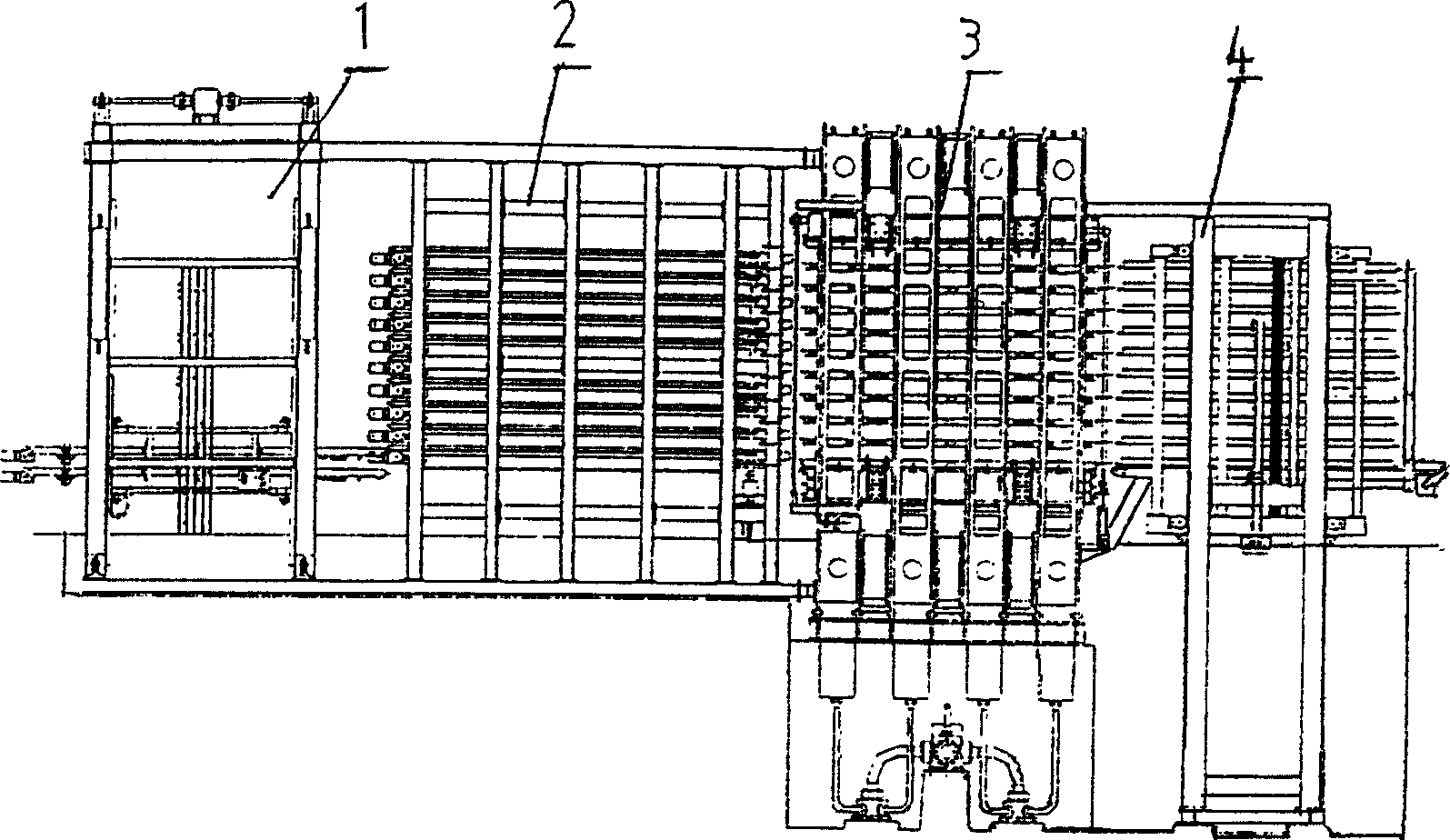

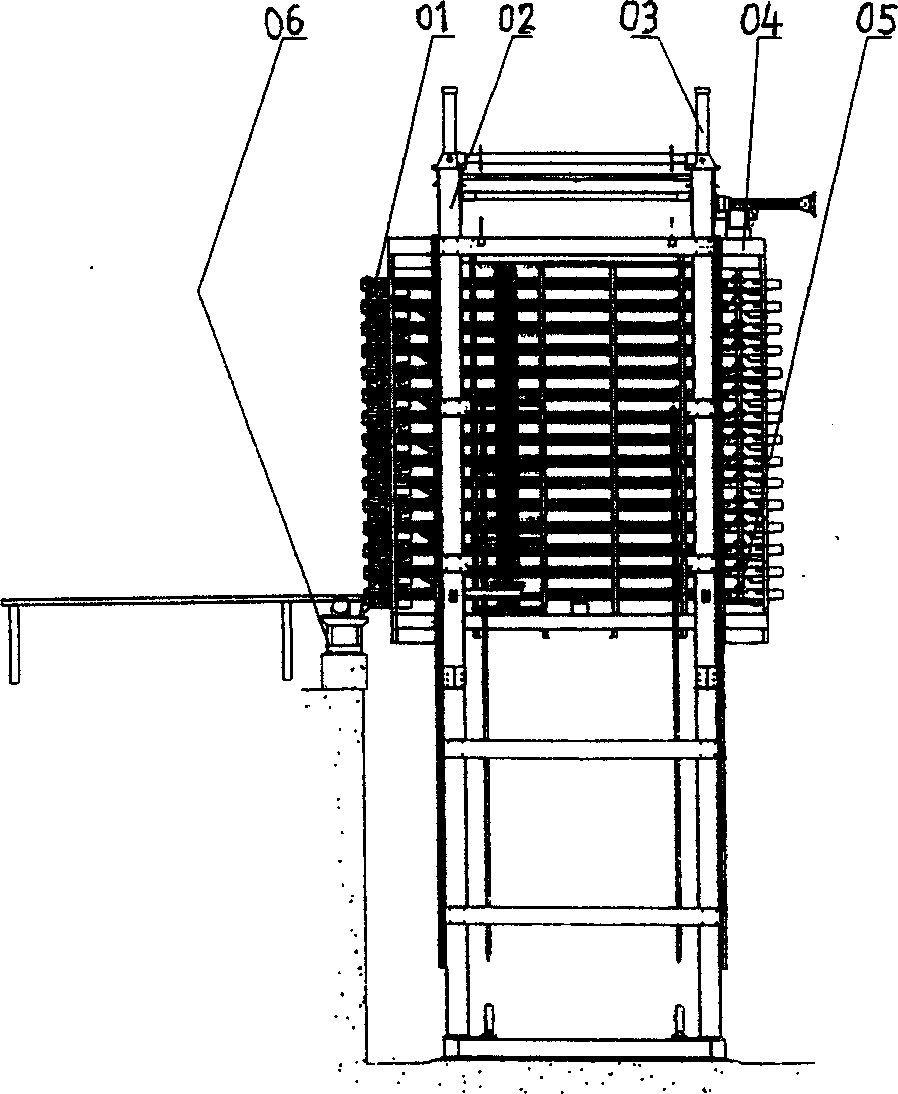

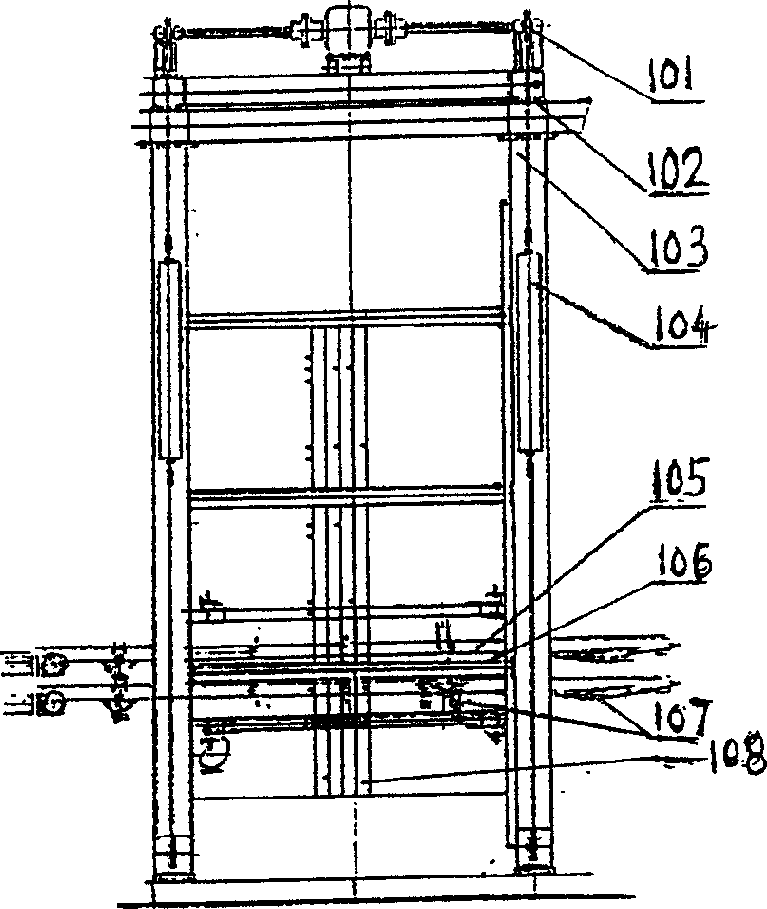

[0028] According to attached figure 1 , 3 , 4, 5 and 6 structures assembled wood-based panel production line hot-press loading and unloading unit, it is characterized in that: in pre-loading machine ( image 3), the drive unit 101 mounted on the top of the whole frame is mainly driven by a motor reducer with a speed ratio of 61.02 and a power of 22kw to drive four sprockets with a pitch of 31.75 through a shaft coupling made of four 45# steels. The chain completes the lifting action of the trolley conveyor 105 on the second floor, the lifting speed reaches 23.8 meters per minute, and the speed of the trolley conveyor reaches 60 meters per minute, all of which can be adjusted by frequency conversion to meet the needs of the production cycle. The four colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com