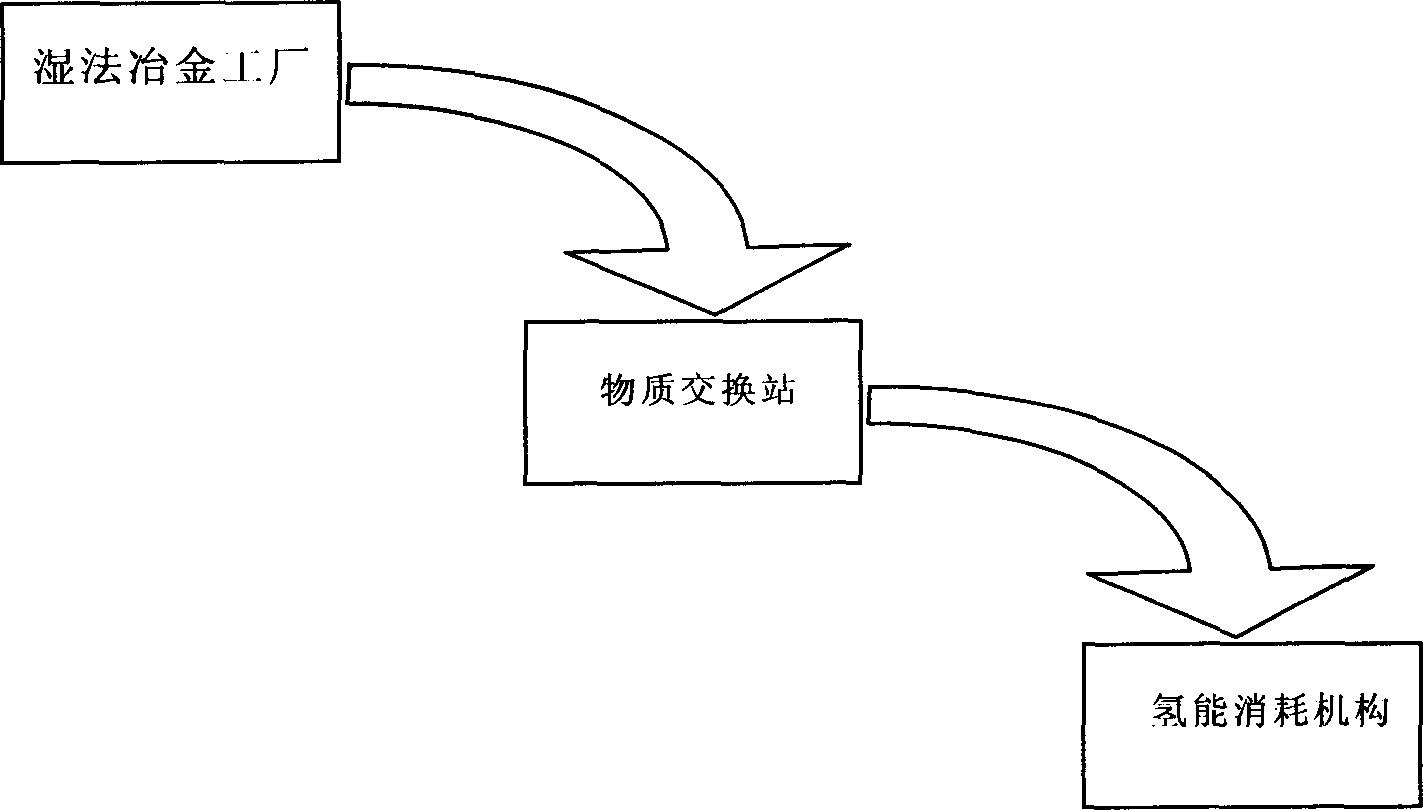

Hydrogen energy circulation method by using metal in height ratio surface area as carrier

A high specific surface area, metal technology, applied in non-metallic elements, chemical instruments and methods, hydrogen and other directions, can solve the problems of easy explosion, easy leakage of hydrogen storage and supply system, etc., to achieve low production cost, easy maintenance and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

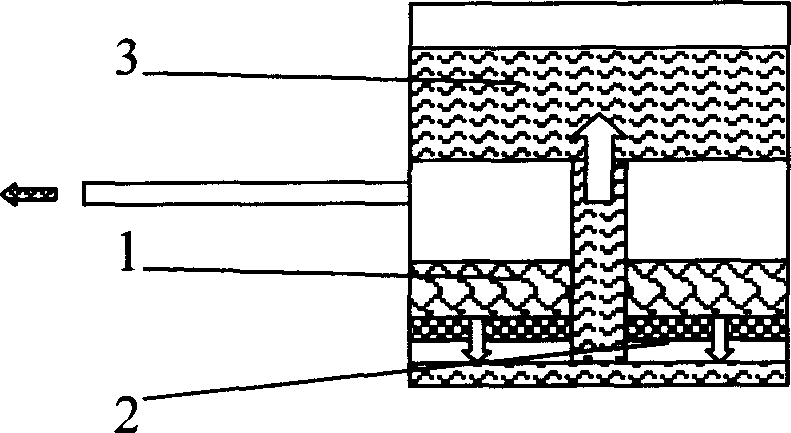

[0035] Example 1: Using metal aluminum as a carrier, the system is used as a hydrogen source for a hydrogen-burning engine

[0036] Aluminum is made into a metal with a high specific surface area, such as metal aluminum powder with a diameter of about 50 μm, and reacts with water at a ratio of 1:3. The actual amount of 27 kg of metal aluminum powder and 54 kg of water is added to the Into the reaction vessel, about 50 mg of a catalyst such as sodium borate is then added while the reaction vessel is sealed.

[0037] Connect the gas outlet of the reaction vessel with the hydrogen inlet of the gas engine, start the gas engine, react with the aluminum powder and water, and start supplying gas to the gas engine.

[0038] After calculation, the energy generated by it can support an ordinary family car (fuel consumption 10 liters / 100 kilometers) to travel 100 kilometers.

[0039] After the reaction is over, the reaction container is recycled through the recovery system, and aluminum...

Embodiment 2

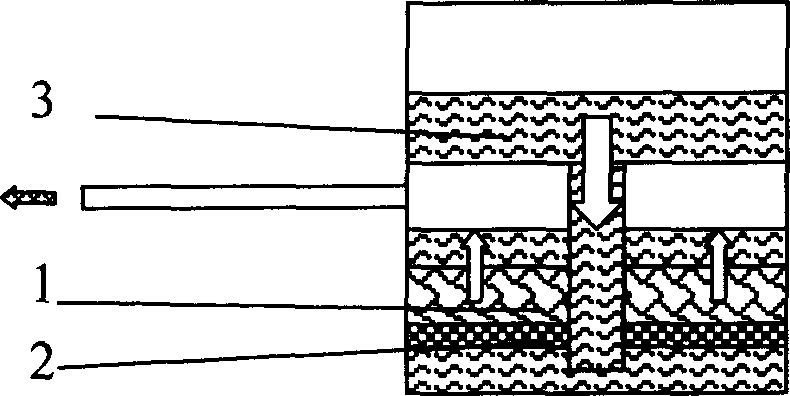

[0040] Example 2: Using metal aluminum as a carrier, the system is used as a hydrogen source for a fuel cell

[0041] Aluminum is made into a metal with a high specific surface area, such as metal aluminum powder with a diameter of about 50 μm, and reacts with water at a ratio of 1:3. The actual amount of 27 kg of metal aluminum powder and 54 kg of water is added to the Into the reaction vessel, about 50 mg of a catalyst such as sodium borate is then added while the reaction vessel is sealed.

[0042] Connect the gas outlet of the reaction vessel with the hydrogen inlet of the fuel cell, start the fuel cell, the aluminum powder reacts with water, and starts to supply gas to the fuel cell.

[0043] With an energy conversion efficiency of about 80% of the fuel cell, about 80KWh of electricity can be generated.

[0044] After the reaction is over, the reaction container is recycled through the recovery system, and aluminum powder is regenerated in the electrolytic aluminum facto...

Embodiment 3

[0045] Example 3: Using metal aluminum as a carrier, the system is used as a hydrogen source for a hydrogen-burning engine

[0046] Aluminum is made into a metal with a high specific surface area, such as metal aluminum powder with a thickness of about 100 μm, and reacts with water at a ratio of 1:3. The actual amount of 27 kg of metal aluminum powder and 60 kg of water is added to the Into the reaction vessel, about 50 mg of a catalyst such as sodium borate is then added while the reaction vessel is sealed.

[0047] Connect the gas outlet of the reaction vessel with the hydrogen inlet of the gas engine, start the gas engine, react with the aluminum powder and water, and start supplying gas to the gas engine.

[0048] After calculation, the energy generated by it can support an ordinary family car (fuel consumption 10 liters / 100 kilometers) to travel 100 kilometers.

[0049] After the reaction is over, the reaction container is recycled through the recovery system, and alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com