Method for controlling liquid level through probe in kiln

A liquid level control and probe technology, which is applied in the direction of manufacturing tools, glass furnace equipment, glass manufacturing equipment, etc., can solve the problems of glass liquid level automatic control kiln working condition stability impact, false detection signal, etc., to achieve stable control, Guaranteed the effect of stable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

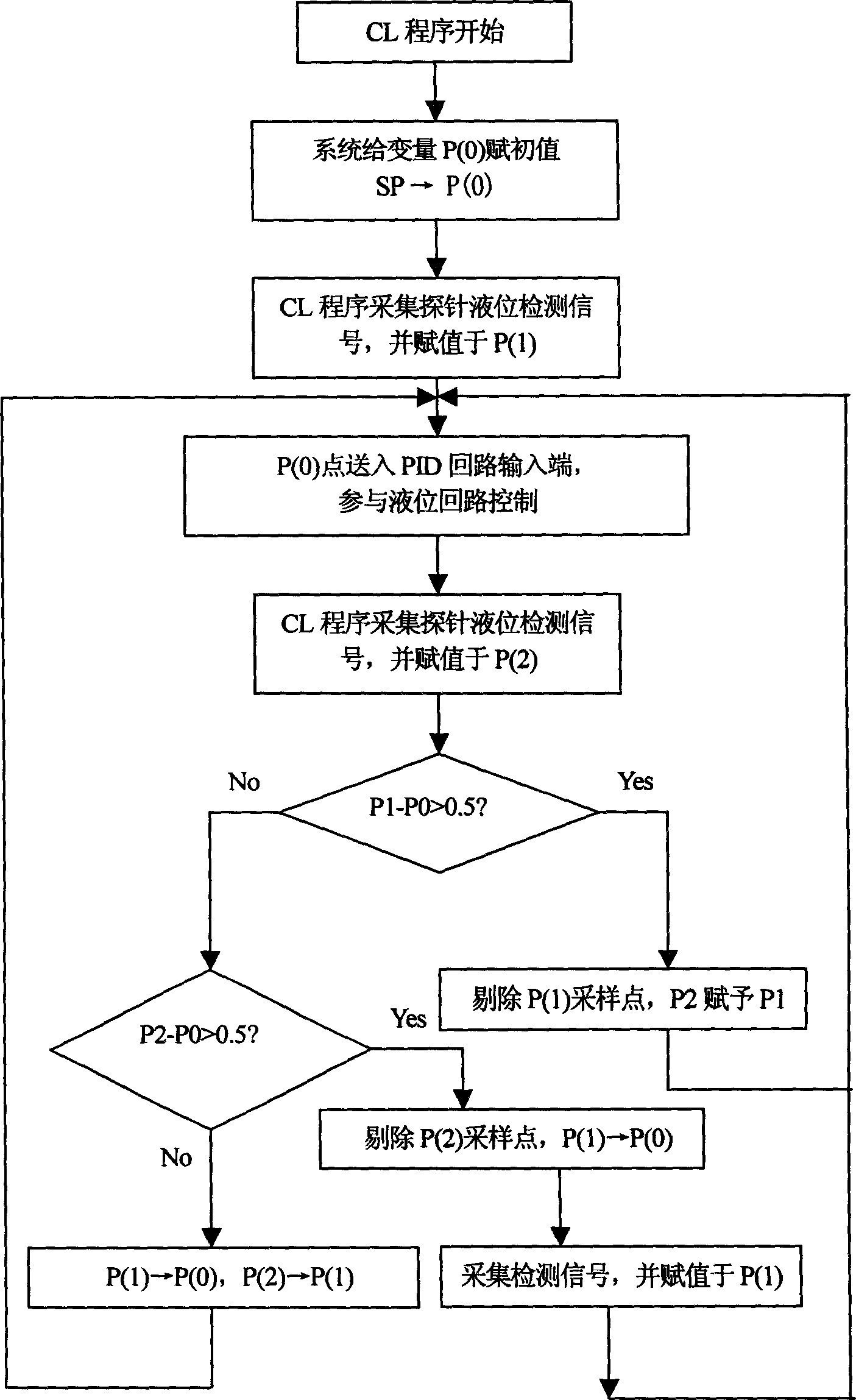

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings.

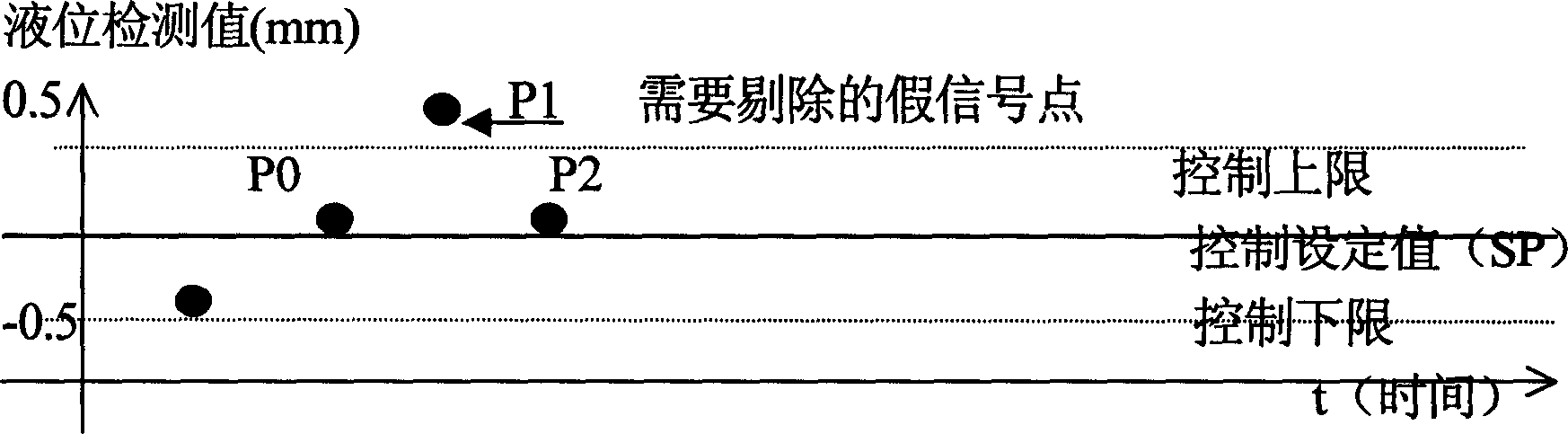

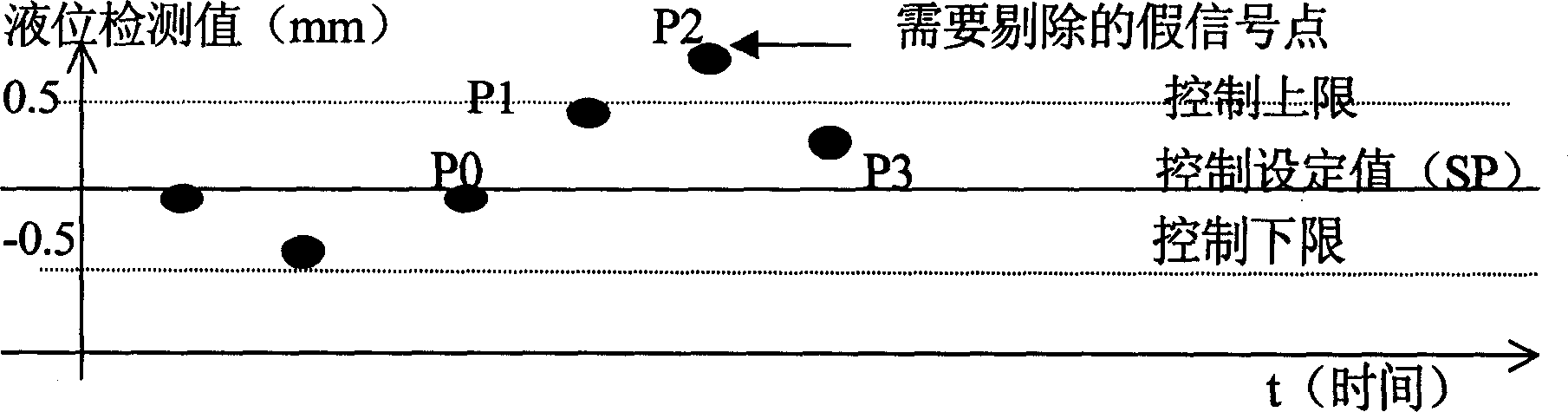

[0010] see figure 1 , 2, where the liquid level reference value P(0) is the effective value confirmed by the control system, the liquid height values P(1), P(2) are the subsequent continuous detection sampling values, and the ±0.5mm in the coordinates is the glass The deviation limit between the process detection value and the set value in the liquid level control system is the control upper and lower limits. It can be seen from the diagram figure 1 The liquid level height value P(1) in figure 2 The liquid level height value P(2) in is a false signal point that needs to be eliminated in the present invention. In the probe liquid level control system, if the deviation between the actual detection value and the set value is within ±0.5mm, the target is considered to be under control; The control loop is adjusted normally, and the control system will iden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com