Blowout prevented fire hydrant, and fire fighting terminal providing flux information

A fire hydrant and anti-surge technology, applied in the field of fire hydrant flow measurement device, fire hydrant anti-surge valve, anti-surge fire hydrant and flow information fire terminal field, can solve the problem of no detection device or communication device, no water flow for fire hydrant, no water source waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

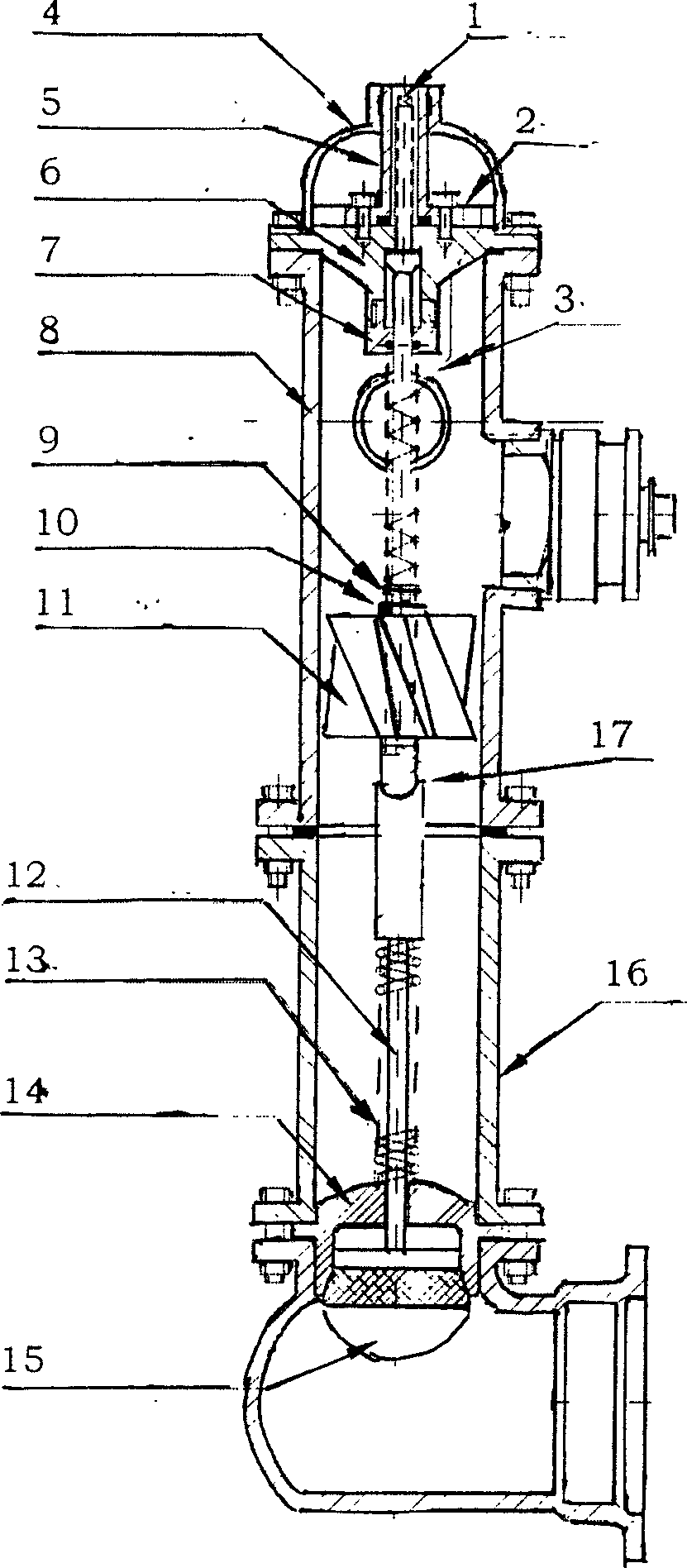

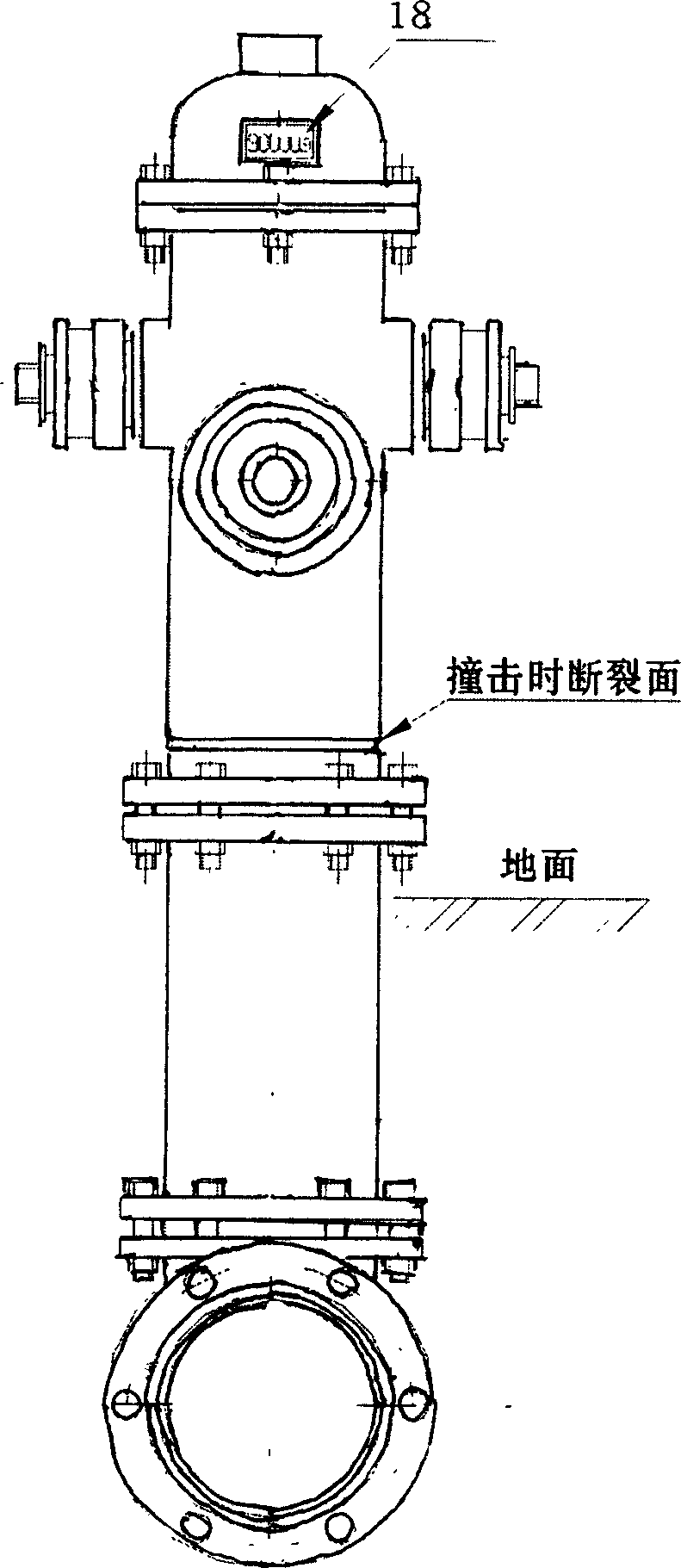

[0026] Embodiment 1, with reference to Fig. 1~ figure 2 :

[0027] The anti-splash fire hydrant has an upper body 8 and a lower body 16. The upper and lower bodies are connected by bolts or screws. parts. The upper bolt body 8 is provided with a valve bolt and a valve bolt rod 1, and the lower end of the valve bolt rod is connected with an anti-surge valve: the anti-surge valve is composed of a leaky valve seat 14 and a conical valve disc 15, and the conical valve disc 15 is connected There is a disc rod 12 on which a spring 13 is arranged; the disc rod and the valve bolt rod are connected through a hemispherical joint 17 . The hemispherical joint 17 connecting the valve screw rod and the disc rod is arranged at the connection plane of the upper and lower bolt bodies, that is, the hemispherical joint is arranged at the position where the fire hydrant is flush with the ground plane or slightly higher than the plane. A metering impeller 11 is installed on the disc rod, the m...

Embodiment 2

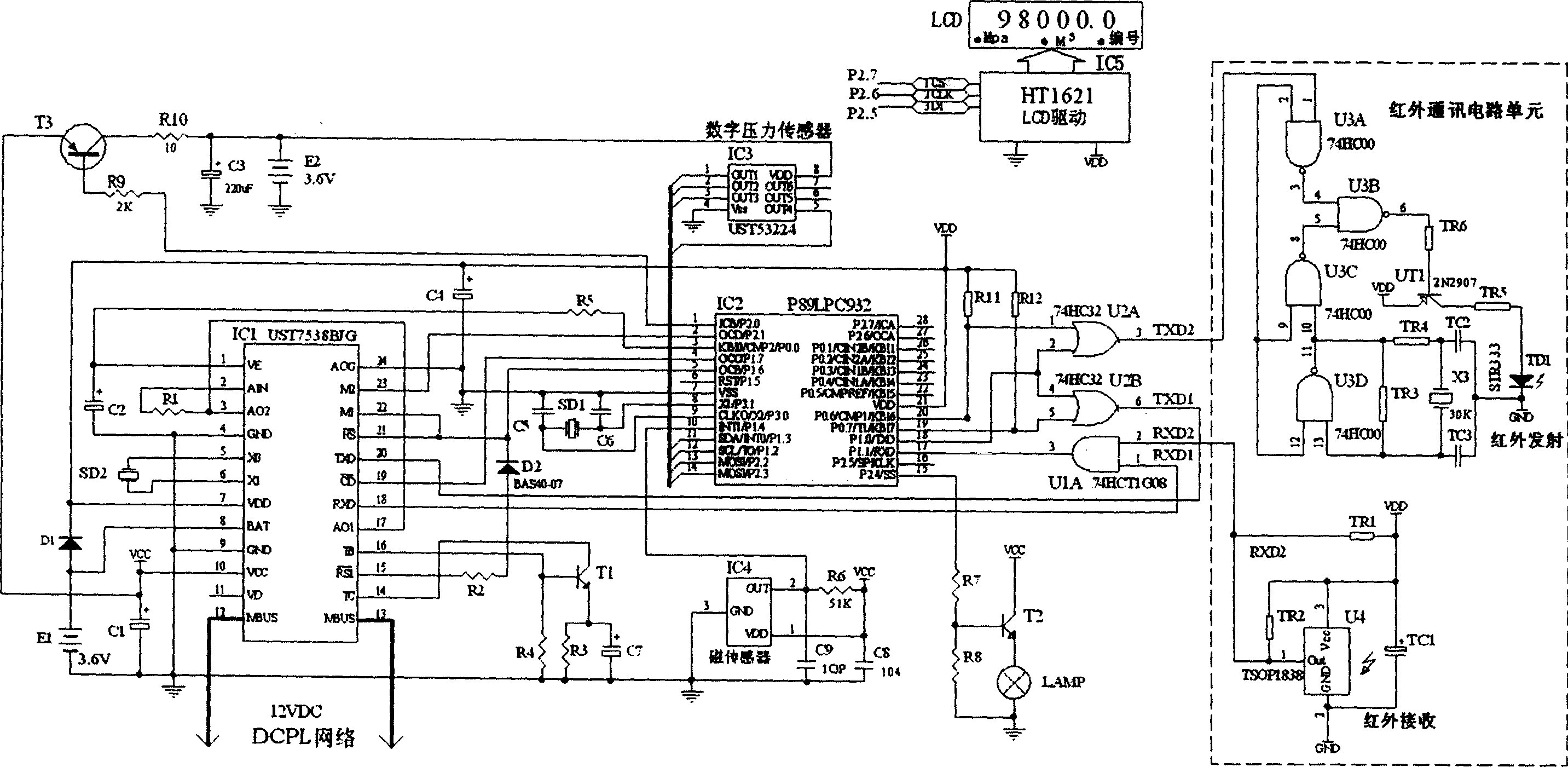

[0034] Embodiment 2 is basically the same as Embodiment 1, but a valve state sensor and a water pressure sensor are provided on the waterway of the fire hydrant, and a microprocessor is provided at the same time; the microprocessor is connected with a DCPL network communication interface circuit, and the flow rate Data acquisition circuit, valve state acquisition circuit, and water pressure detection data acquisition circuit, among which the flow data acquisition circuit, valve state acquisition circuit, and water pressure detection data acquisition circuit are respectively connected with the flow metering device, valve state sensor and water pressure in the fire hydrant. It is connected to the pressure sensor and connected to the network through the communication interface to form a fire hydrant terminal device for flow measurement information. All anti-splash fire hydrants and flow metering information fire hydrant terminal devices are connected to the network for easy monito...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com