Wear test method of twisting jiggle of generating micro iamplitude of vibration, and testing machine

A fretting wear and test method technology, applied in the direction of testing wear resistance, using mechanical devices, measuring devices, etc., can solve problems such as no research on torsional fretting wear, and achieve small errors, few motion links, and constant amplitude. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

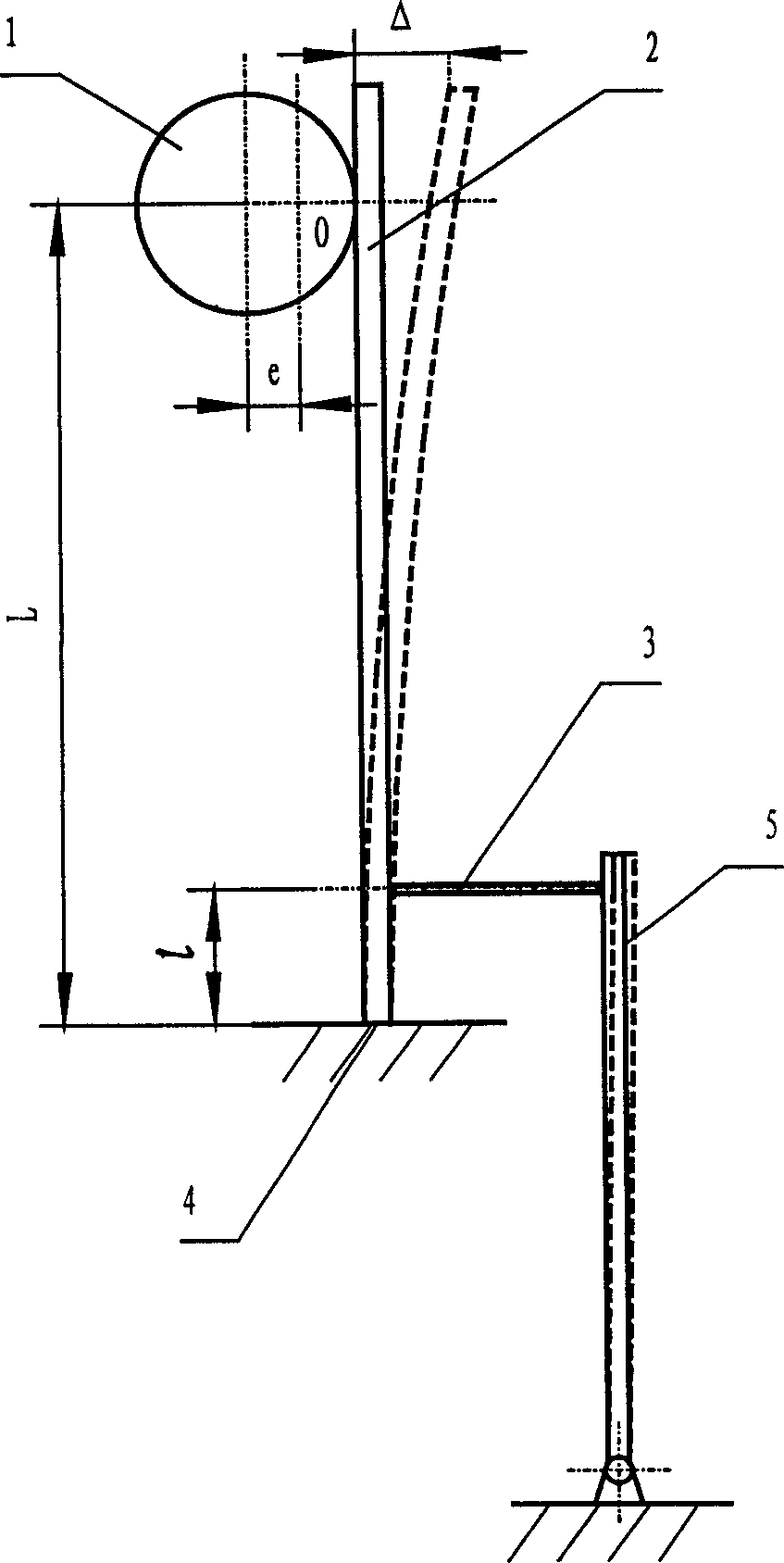

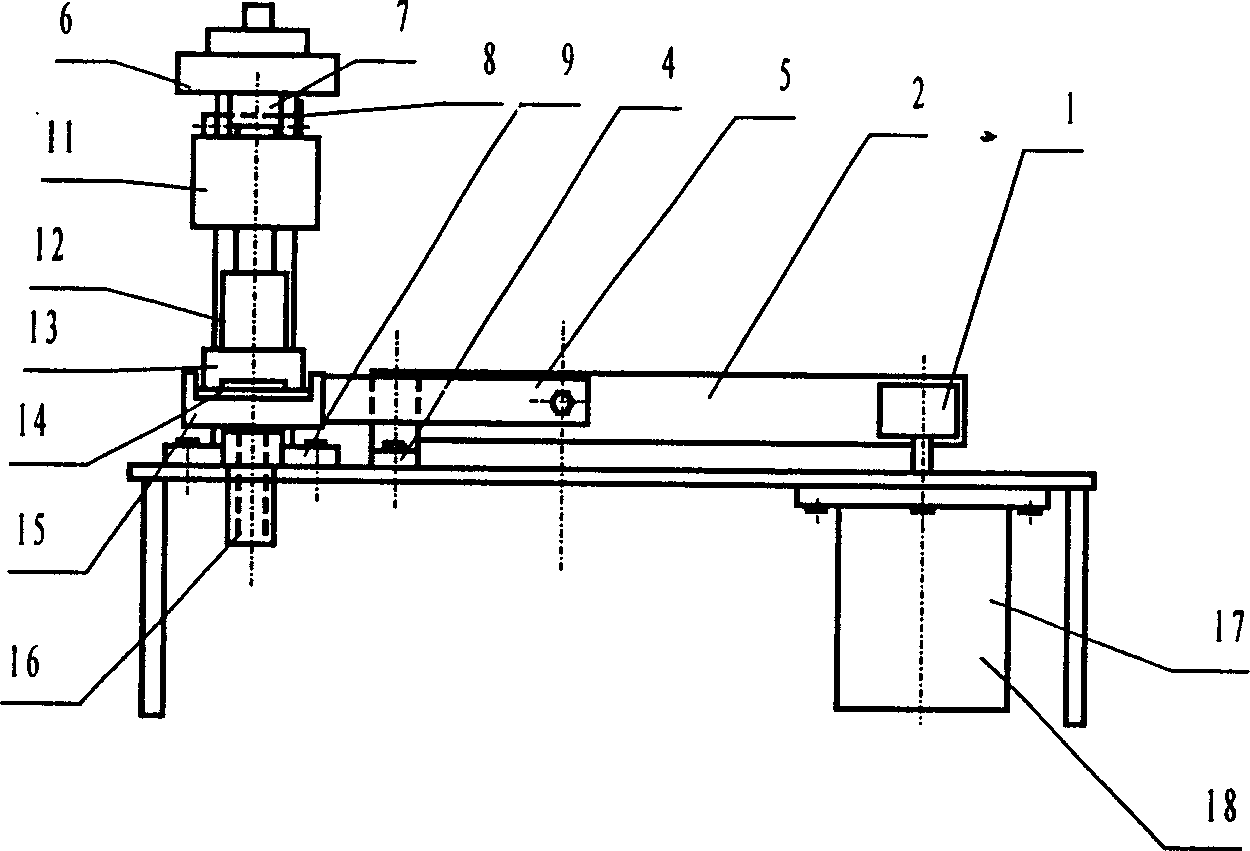

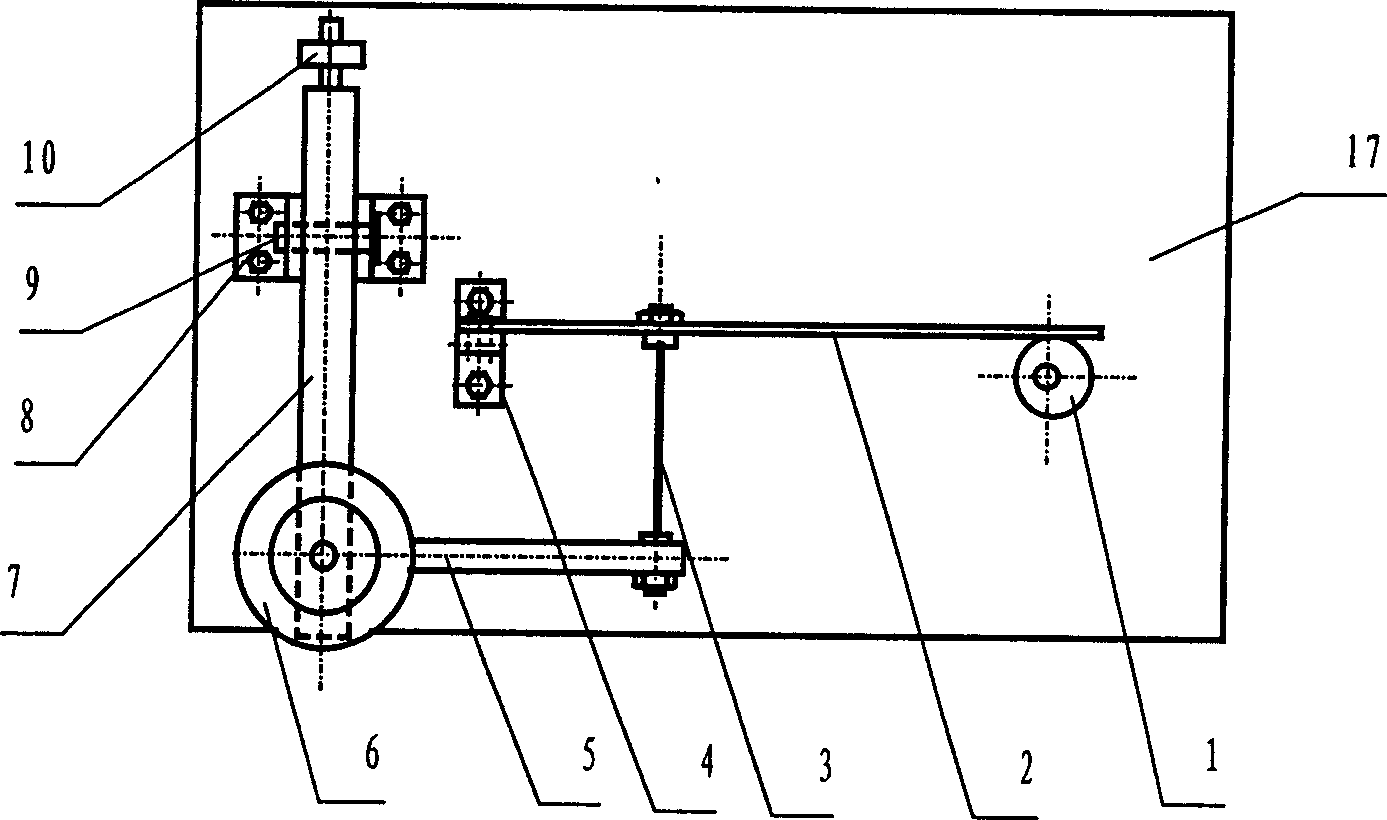

[0020] The twisting and fretting wear test method of the present invention that produces tiny amplitudes adopts a cantilever swing device composed of a cam 1, a cantilever elastic thin plate 2, a small thin plate 3 and a swing rod 5, and a load balance device provided with a torque sensor 11. According to the cantilever beam The principle of elastic bending and leverage ratio amplification to obtain small swing amplitudes, such as figure 1 As shown, the eccentricity of the cam 1 is set as e, the length of the cantilever elastic thin plate 2 from the fixed point to the center distance of the cam 1 is L, and the distance from the center distance of the fixed small thin plate 3 is l, so that the small amplitude satisfies: v = e · l 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com