Block removing type pipe scraper

A technology for pigging and unblocking, which is applied in the direction of cleaning hollow objects, chemical instruments and methods, cleaning methods and utensils, etc., to achieve the effect of expanding the scope of operation and improving the efficiency of operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Now further illustrate the specific structure and operation mode of the present invention in conjunction with accompanying drawings and embodiments.

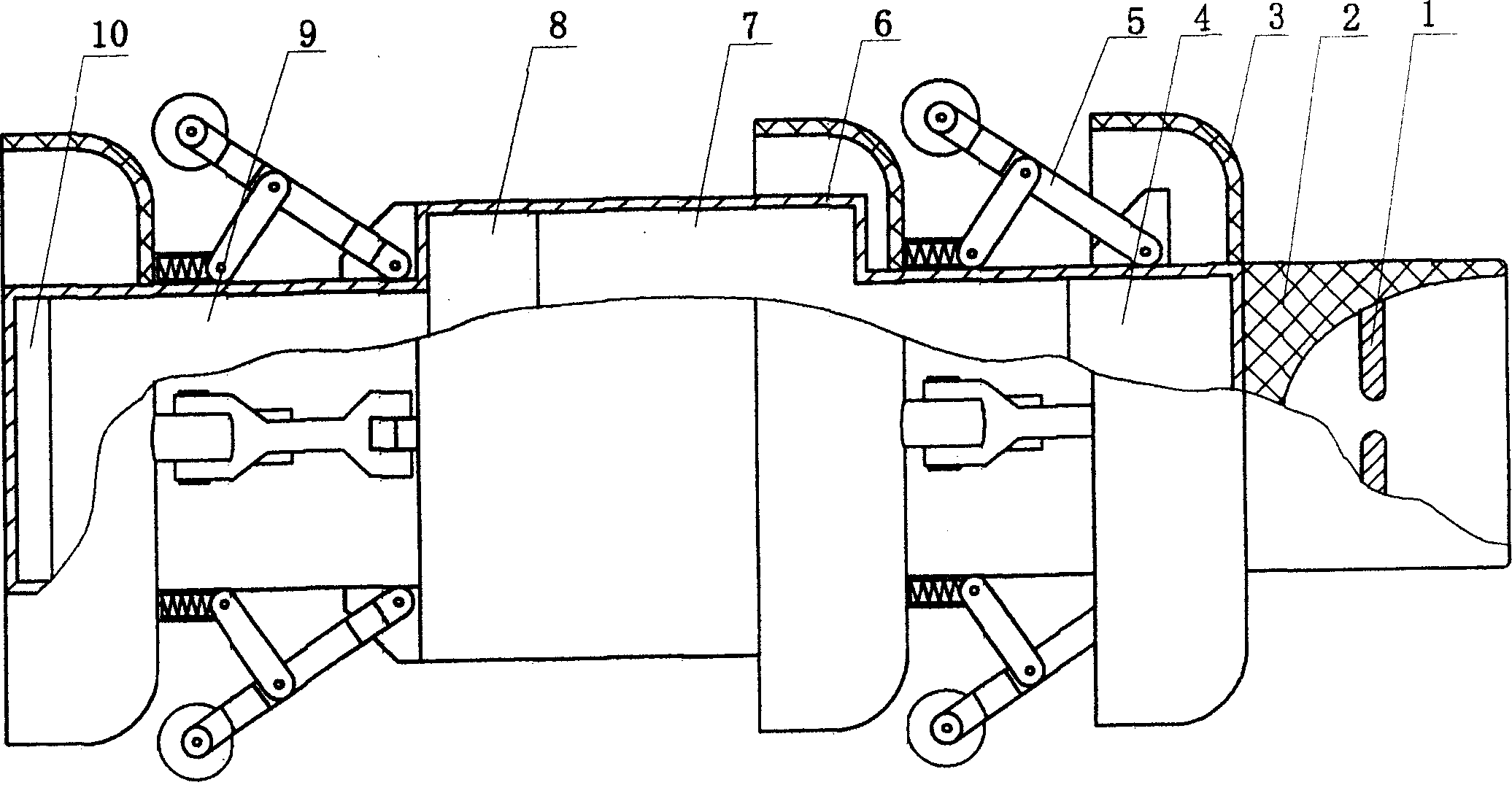

[0012] Figure 1 It is a schematic diagram of the structure of a plug-removing pig.

[0013] Such as Figure 1 In the shown embodiment, the blockage-removing pig is composed of a cleaning-type pig and a generating device. It can be seen from its appearance that it is basically a cleaning type cup cleaner, but there is a discharge unit (1, 2) of a generating device at its front end, and its skeleton is the housing (6) of the generating device. The structure of the skeleton is designed and manufactured according to the technical requirements of the pig and the generating device, that is, compressive strength, high voltage resistance, sealing, and shockproof. In this embodiment, the housing (6) has a cylindrical structure, and its diameter is not larger than 1 / 2 of the outer diameter of the pig, but there is a protrusion in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com