Improved toluene disproportionation process

A process method and toluene technology, applied in the field of improved toluene disproportionation and transalkylation processes, can solve the problems of complicated process and increase equipment investment, and achieve the effects of reducing cooling load, saving consumption and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

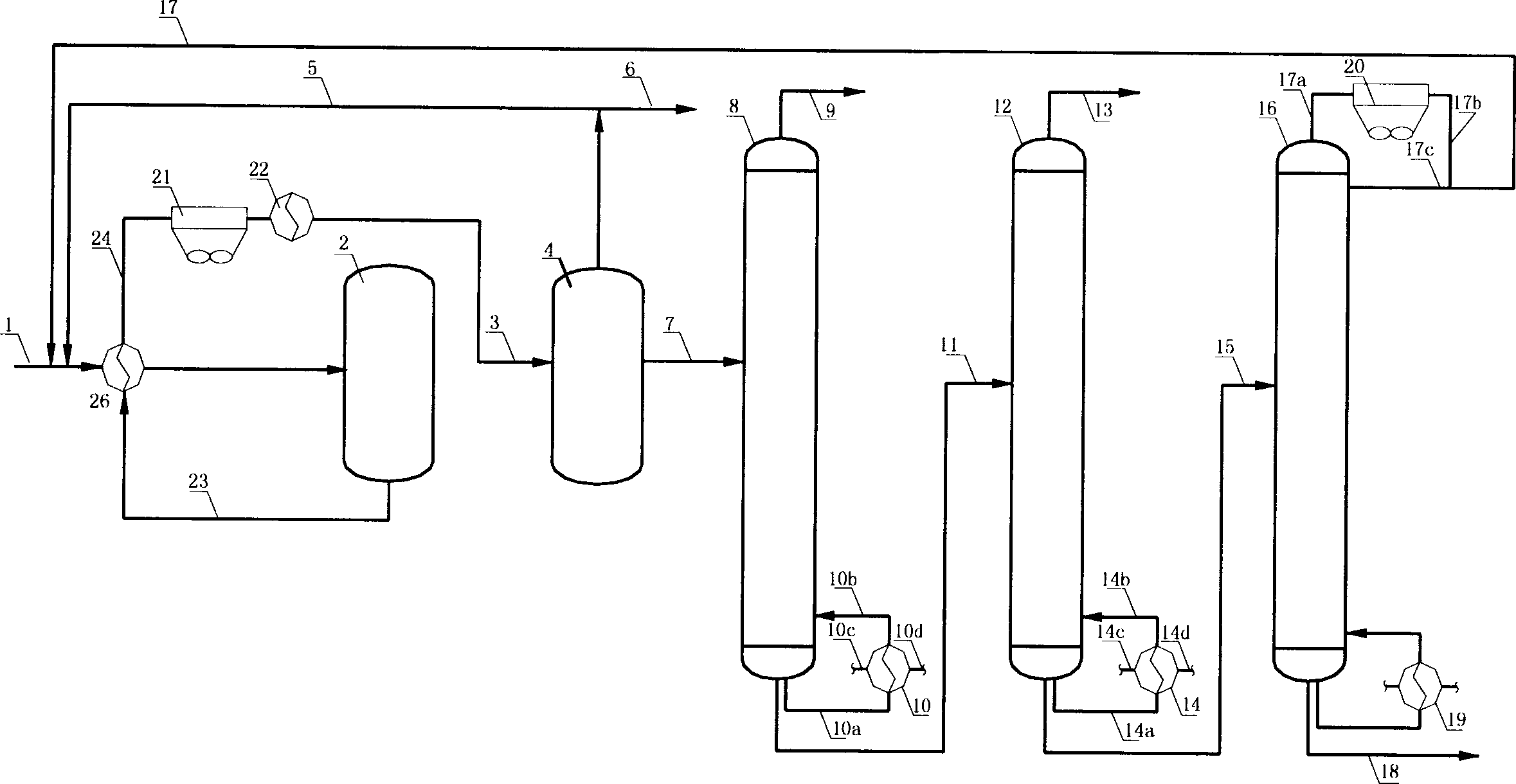

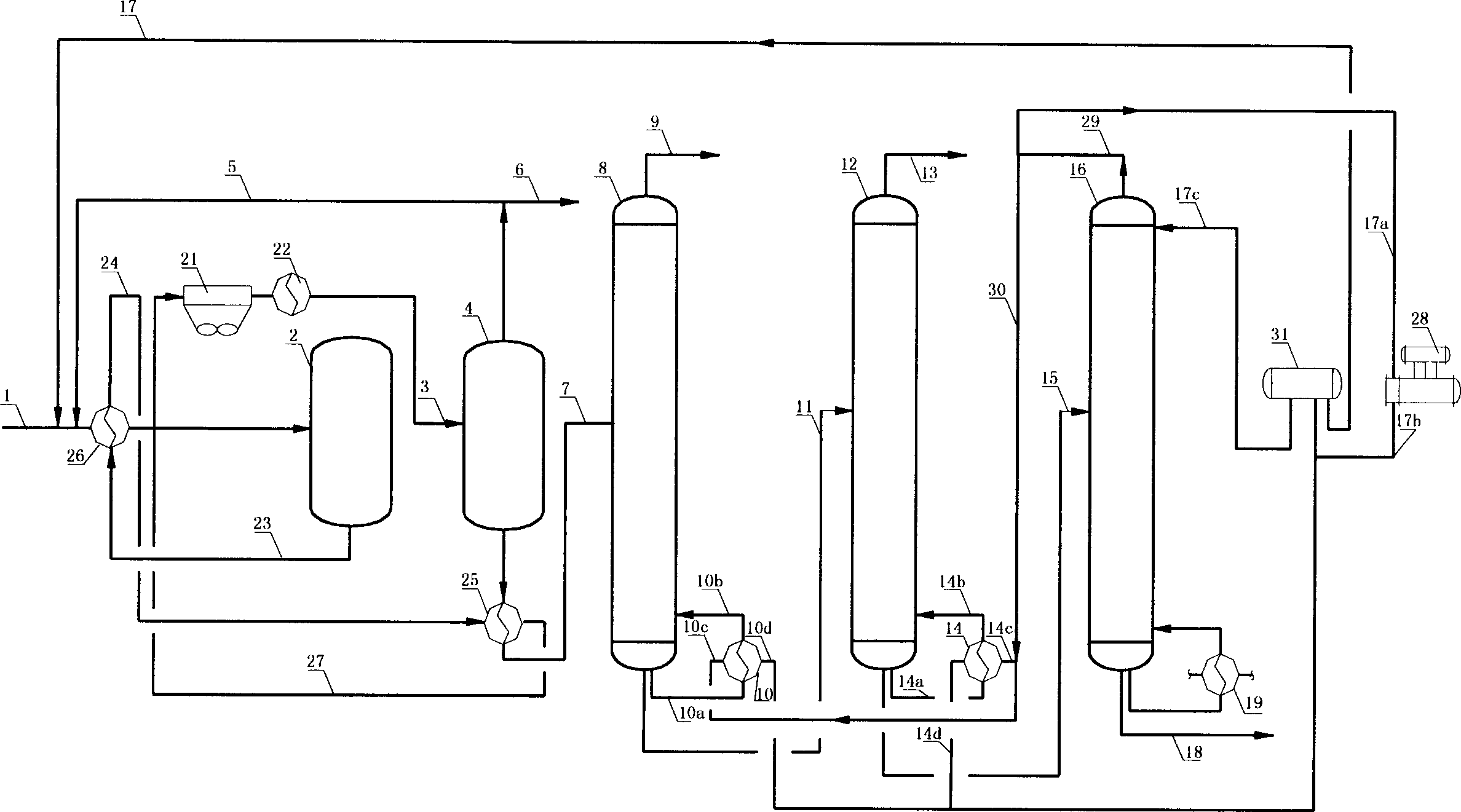

[0033] The flow of this embodiment is figure 2 The improved toluene shape-selective disproportionation process, the toluene tower is operated under pressure, and the heat source of the reboiler of the stabilization tower, benzene tower and steam generator is toluene steam connected in series.

[0034] Taking 25000kg / h fresh toluene feed as an example, the fresh toluene raw material and its properties and reaction liquid products are the same as those of the comparative example. The results of the temperature and heat load of each tower are shown in Table 2. From the data in Table 2, it can be seen that since the toluene tower adopts a pressurized design operation, when the pressure is increased to 1MPa, the temperature of the toluene tower overhead steam after passing through the benzene tower reboiler is 217.2°C, and the gasification rate becomes 0.478 , and then after passing through the reboiler of the stabilizing tower, the temperature is still 217.2°C, and the gasificati...

Embodiment 2

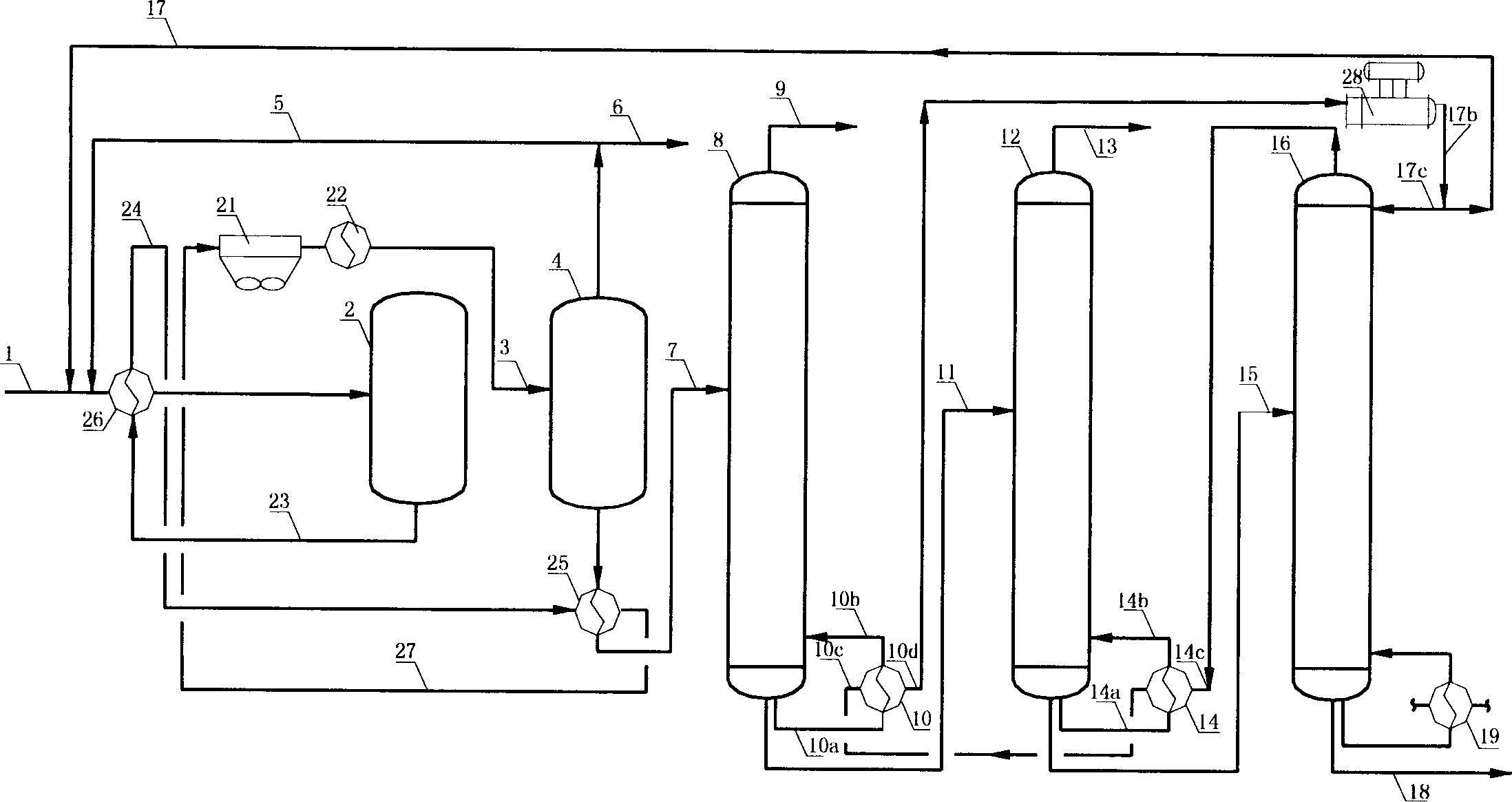

[0036] The flow of this embodiment is image 3 The improved toluene shape-selective disproportionation process, the toluene tower is operated under pressure, and the heat source of the reboiler of the stabilizing tower, benzene tower and steam generator is toluene steam connected in parallel.

[0037] Taking 25000kg / h fresh toluene feed as an example, the fresh toluene raw material and its properties and the composition of the reaction liquid product are the same as those of the comparative example. The results of the temperature and heat load of each tower are shown in Table 3. The investment in improving the shape-selective disproportionation process increases, but the annual operating cost is reduced due to the reduction of energy consumption. The energy consumption of the improved toluene shape-selective disproportionation process in this example is reduced to 3902 MJ / t.

[0038] Raw material properties

[0039] comparative example

[0040] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com