Sub-stabilisation austenitic stainless steel belt of weary characteristic fine used by metal shrapnel and metal shrapnel

A technology of austenitic stainless steel and metal shrapnel, which is applied to improve the fatigue properties under high stress. In the field of metal shrapnel, it can solve the problems of no improvement in durability, no clear durability, and difference in durability, and achieve the effect of excellent fatigue properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Next, preferred embodiments of the present invention will be described.

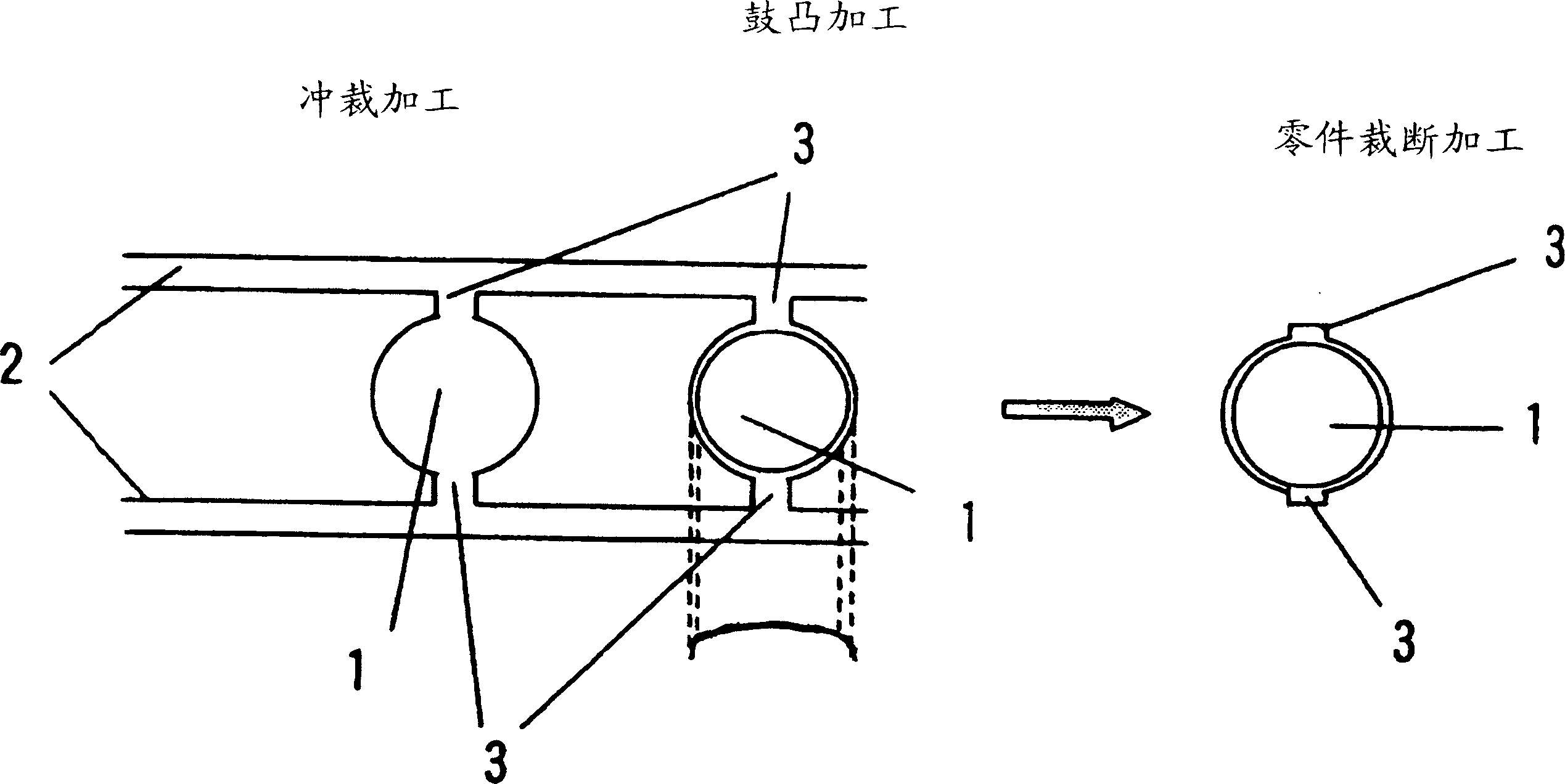

[0018] 1. Production of metal shrapnel

[0019] A raw material bar of austenitic stainless steel (SUS301) with a plate thickness of 1.5mm and solution treated is subjected to repeated cold rolling and recrystallization annealing, and finally processed to a plate thickness of 0.06mm. Stress relief annealing was carried out at a furnace temperature of 500-700° with a residence time in the furnace of 10-40 seconds to obtain raw material strips of samples A-E. Here, all the samples A to E were subjected to repeated cold rolling and recrystallization annealing two or more times, and the above-mentioned stress relief annealing was performed after the final cold rolling. The working degree of samples A, D, and E in cold rolling was 20% to 70%, and in recrystallization annealing, the conditions were adjusted so that the crystal grain size number was in the range of No. 7 to No. 10. In this case, the 0.2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap