Method for producing stamper used for producing optical disc and optical disc producing method

一种光盘、母盘的技术,应用在用光学方法记录/重现、光学记录载体制造、光学元件等方向,能够解决阻碍生产率、长时间周期、降低产量等问题,达到改善跳动的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments of a method of manufacturing a master for producing an optical disc and a method of producing an optical disc according to the present invention are explained below.

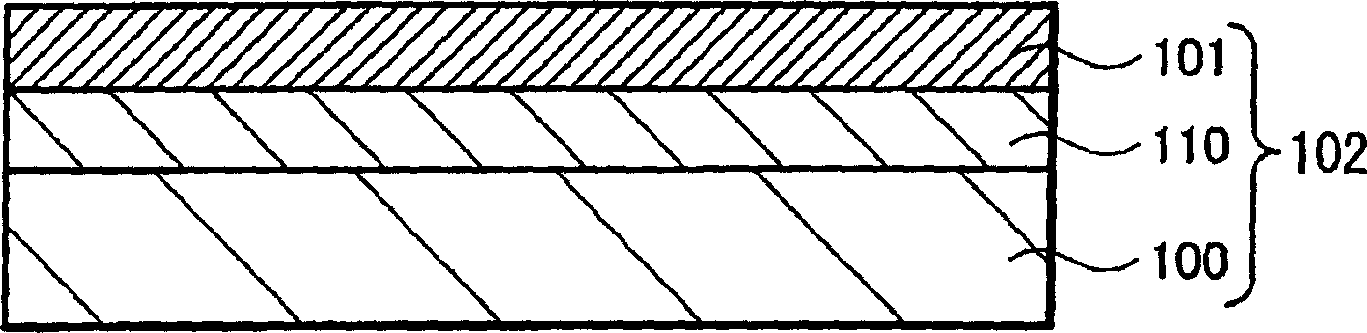

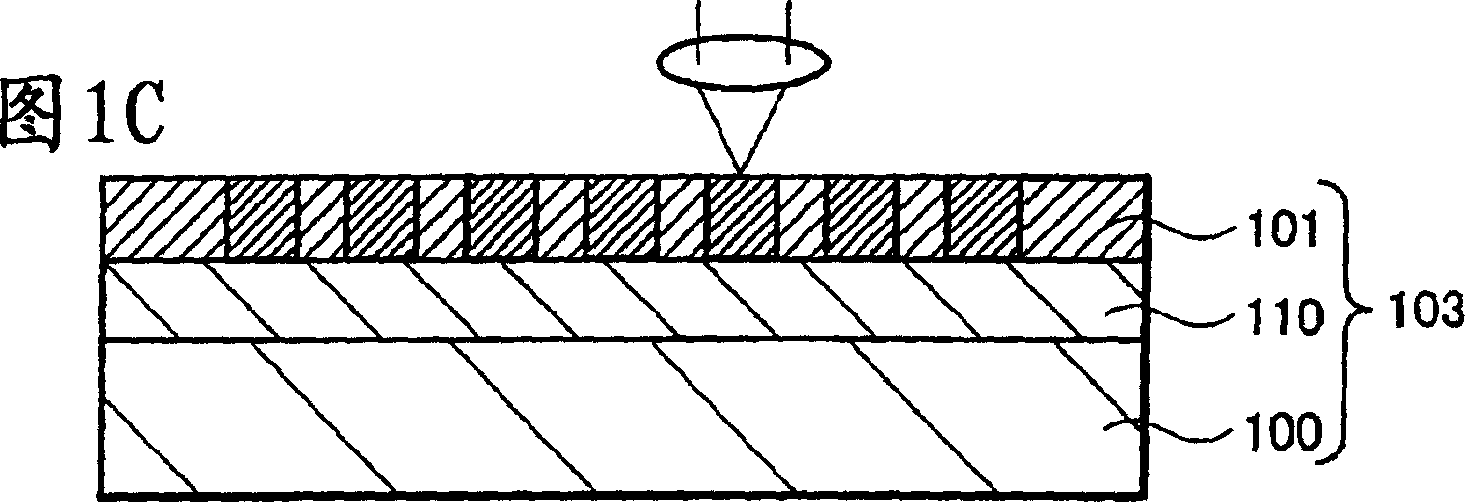

[0042] First, a method of producing an optical disc using an inorganic resist material, which is a premise of a method of adjusting its exposure focus position, is explained. As a manufacturing method, there is a method in which, after forming a resist layer made of a resist material containing an incomplete oxide of a transition metal on a substrate, the oxygen content of the oxide is less than that corresponding to the above-mentioned transition metal. The oxygen content of the stoichiometric composition of atomic valences that the metal may have, the resist layer is selectively exposed to correspond to the recorded signal pattern and developed to form predetermined concave and convex patterns.

[0043] Below, by reference to the attached Figures 1A to 1J The processing diagram schematical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com