Capacitor silcion-base microphone and its manufacturing method

A capacitive and microphone technology, applied in the field of capacitive silicon-based micro-microphones and its manufacturing, can solve the problems that the electrode bonding area cannot be exposed, the difficulty of the bonding process increases, and the complexity of the process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

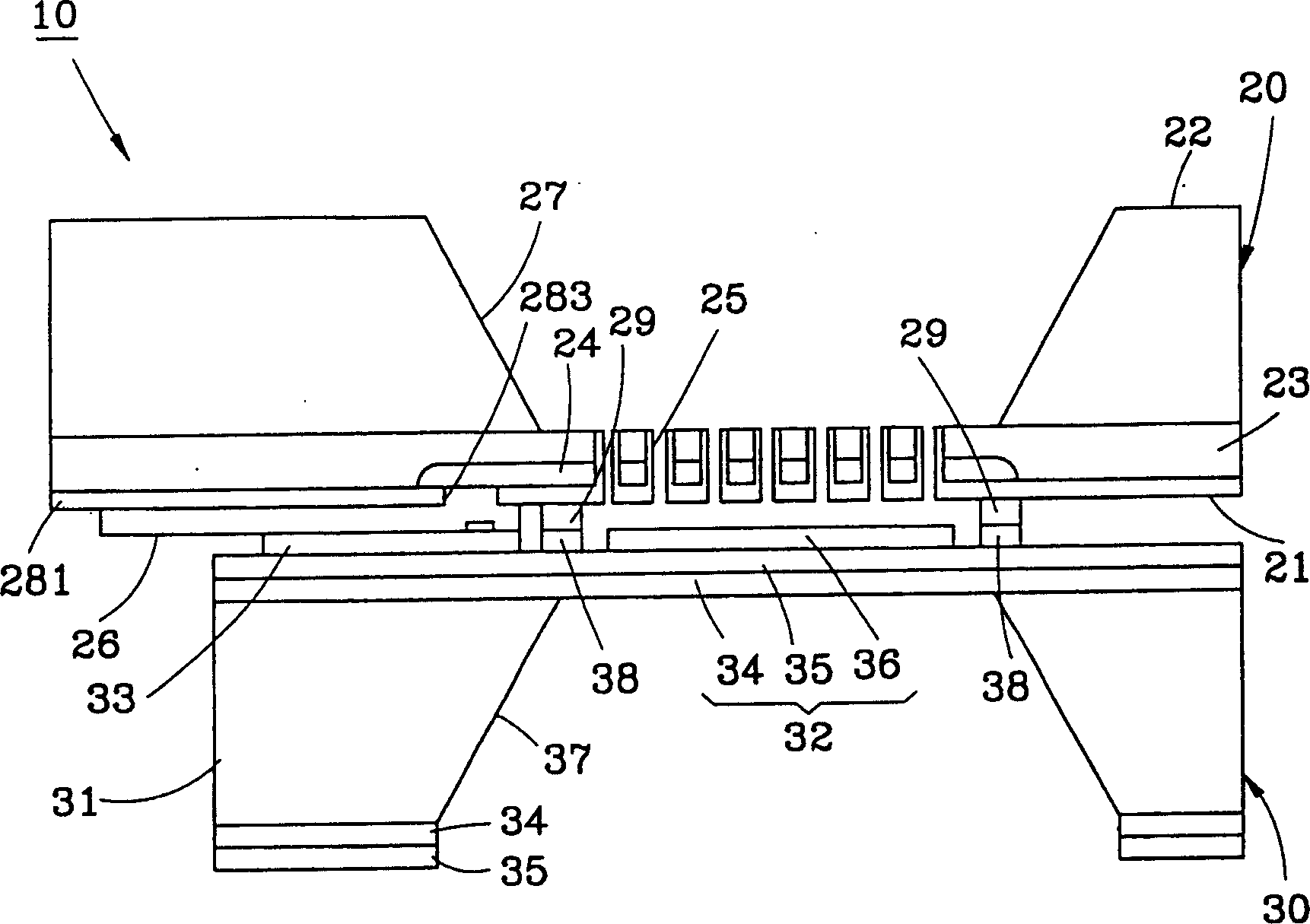

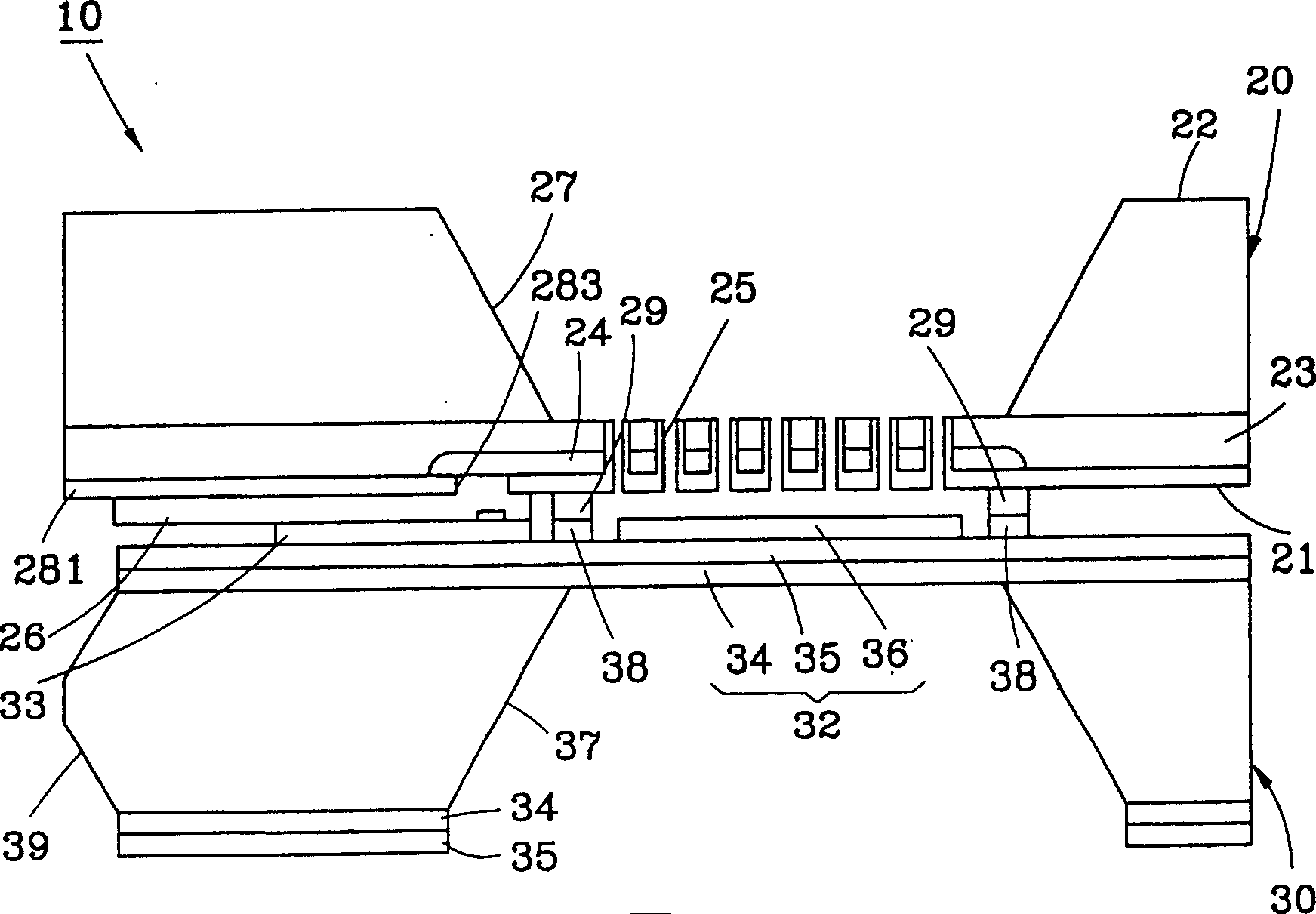

[0021] First, see figure 1 As shown, the present invention provides a capacitive silicon-based micro-microphone 10, which mainly includes a backplane chip 20, and a vibrating chip 30 below the backplane chip 20, wherein:

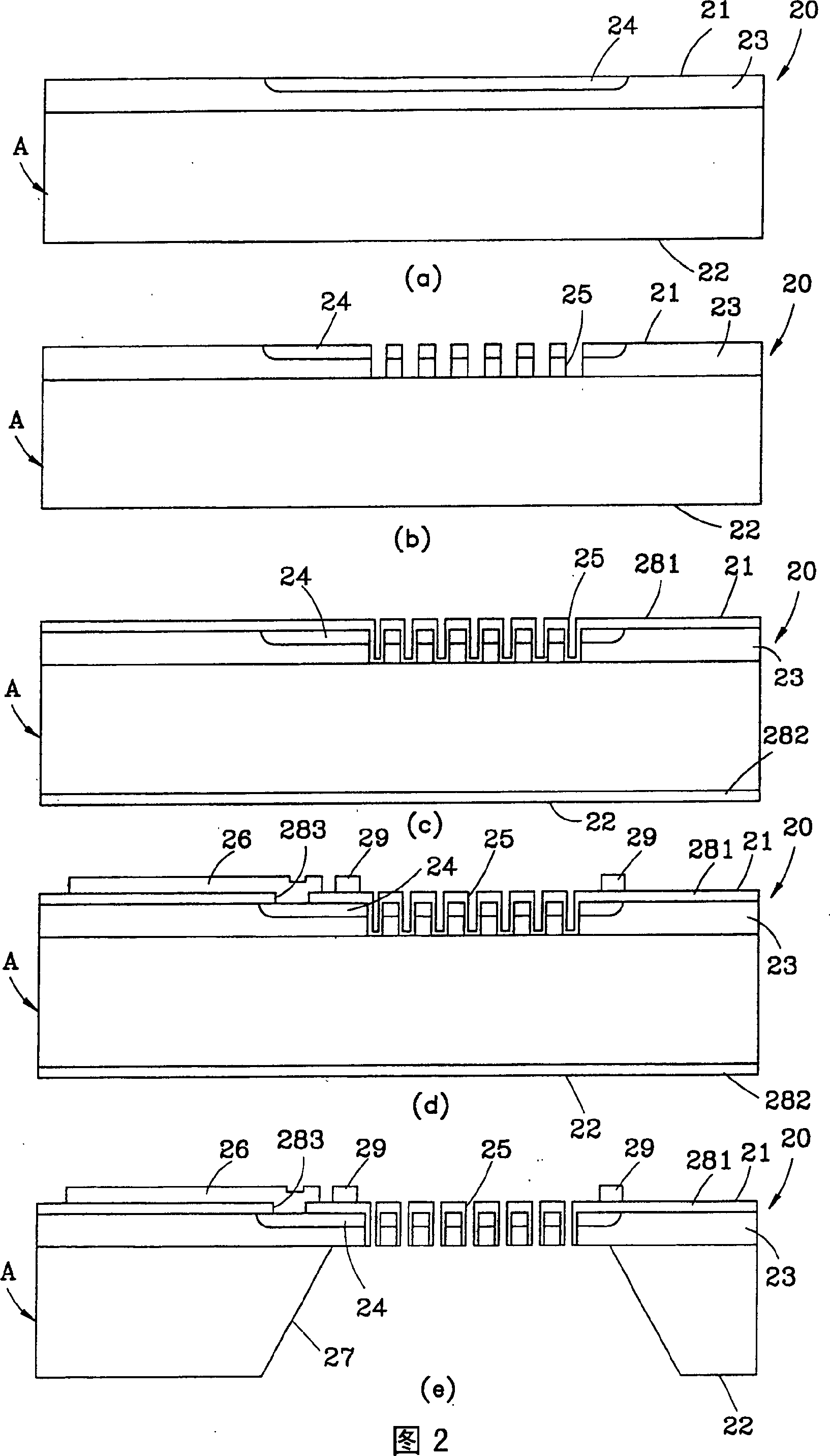

[0022] The backplane wafer 20 has a first surface 21 and a second surface 22 opposite to each other, wherein the first surface 21 is provided with an epitaxial layer 23, a conductive layer 24 doped with P+ ions, a plurality of which penetrate the The epitaxial layer 23 is connected to the sound hole 25 of the conduction layer 24 , and a first electrode 26 electrically connected to the conduction layer 24 , and the second surface 22 defines a resonant groove 27 communicating with the sound holes 25 . Referring to Fig. 2 again, the manufacturing method of the backplane wafer 20 comprises the following steps:

[0023] a. Provide a wafer A with the epitaxial layer 23 on the surface, and then implant P+ ions into the surface of the epitaxial layer 23 to form the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com