Microwave thermal reaction device for graphitizing carbon fiber and processing technique

A processing technology and graphitization technology, which is applied in the fields of fiber chemical characteristics, chemical post-treatment of rayon, textiles and papermaking, etc., can solve problems such as poor dispersion of product technical indicators, huge equipment, and large differences in process conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

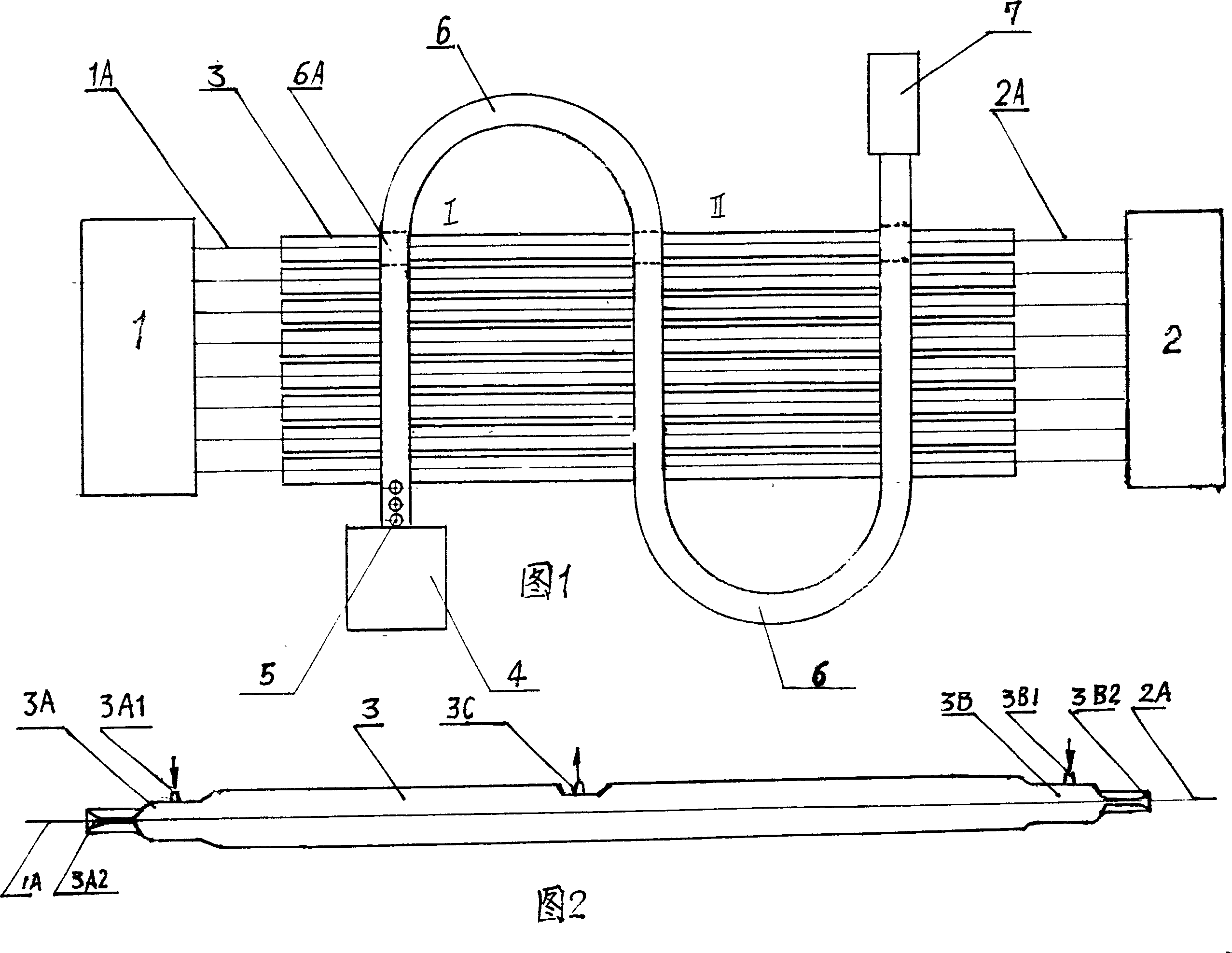

[0012] Microwave thermal reaction device is the key equipment for carbon fiber graphitization treatment. This equipment adopts the principle of waveguide leakage magnetic field induction heating, and uses microwave energy to directly heat carbon fiber to 2500-3000 ° C in an argon environment. Graphitization treatment. Therefore, in addition to the microwave generator 4 capable of generating 915MHZ microwave energy, the device is provided with a power zone distributor 5 in order to adjust the energy of the leakage magnetic field and ensure the realization of the process temperature. The key structure for realizing energy conversion is the serpentine waveguide 6 with the through slots 6A in the radial direction. The serpentine waveguide 6 in Figure 1 will form two induction heating zones I and II, and the water load 7 is used to absorb the remaining energy. The water load can be designed as a circulating water structure to make full use of energy. The role of the quartz tube th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com