Heat pipe radiating unit and manufacturing method thereof

A technology of a heat dissipation device and a manufacturing method, which is applied to tubular elements, heat exchange equipment, indirect heat exchangers, etc., can solve the problems of large thermal resistance, inability to achieve heat dissipation effect, and inability to give full play to the performance of rapid heat conduction of heat pipes. Small size, fast and effective absorption of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the embodiments with reference to the accompanying drawings.

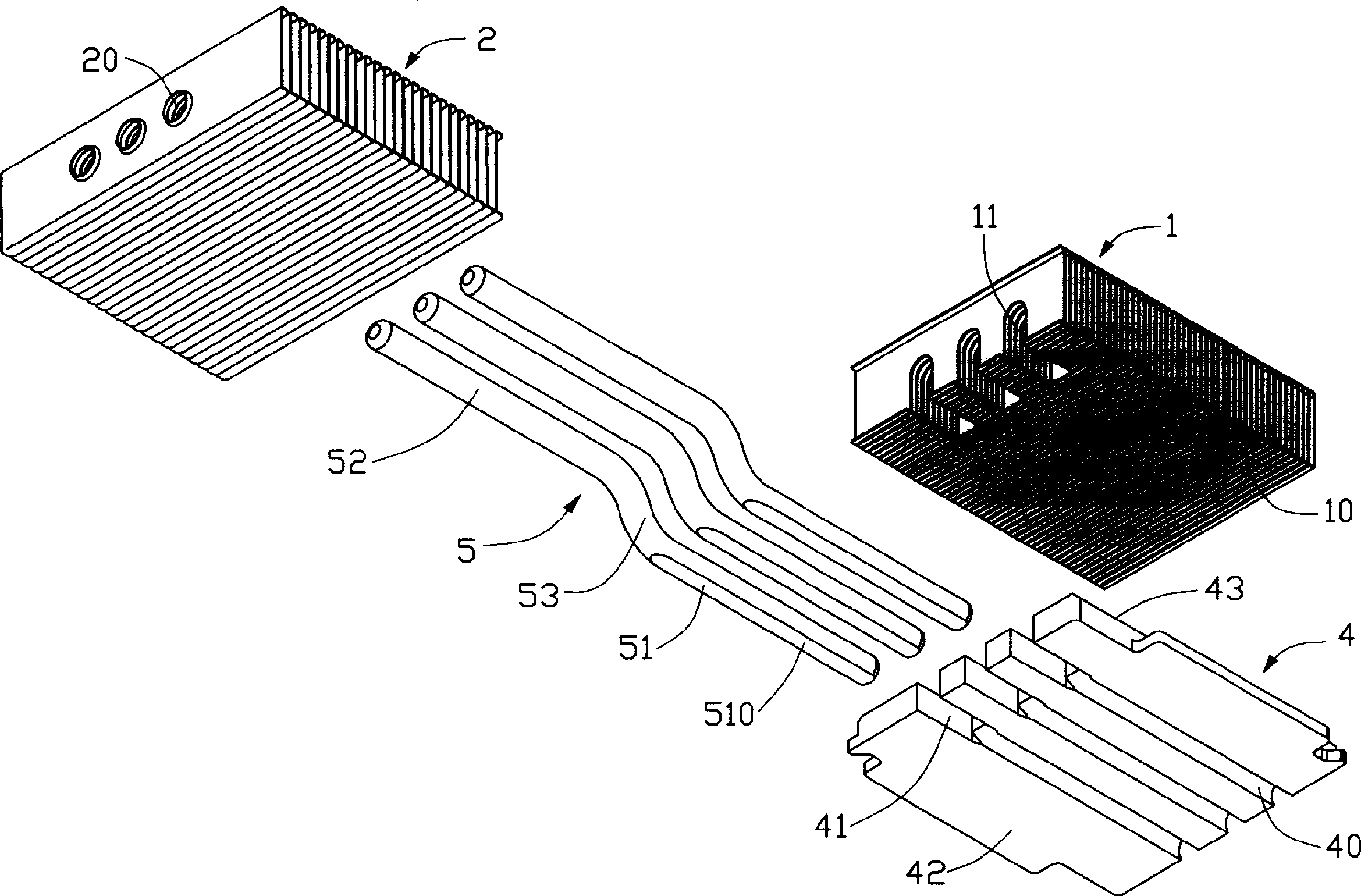

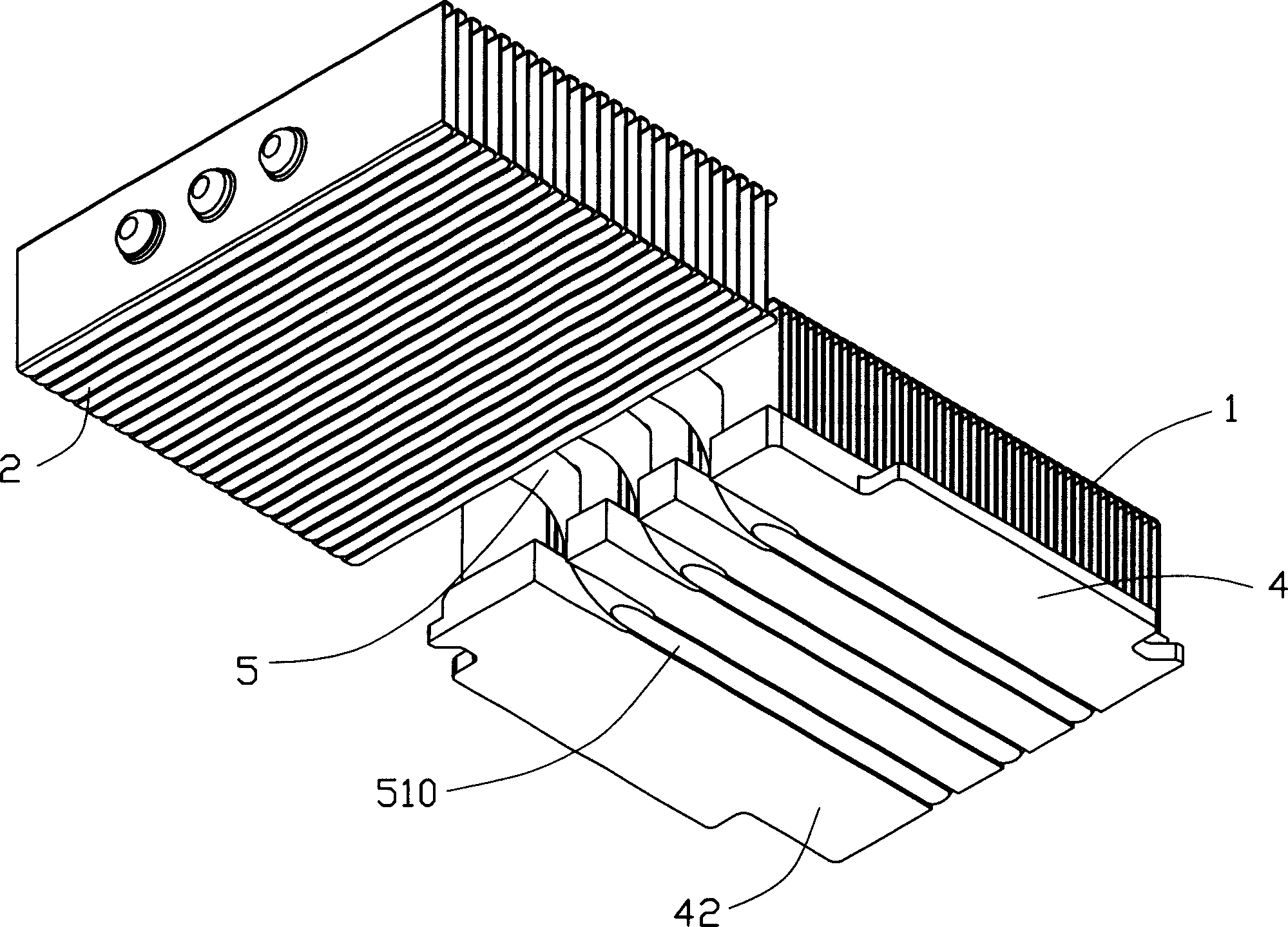

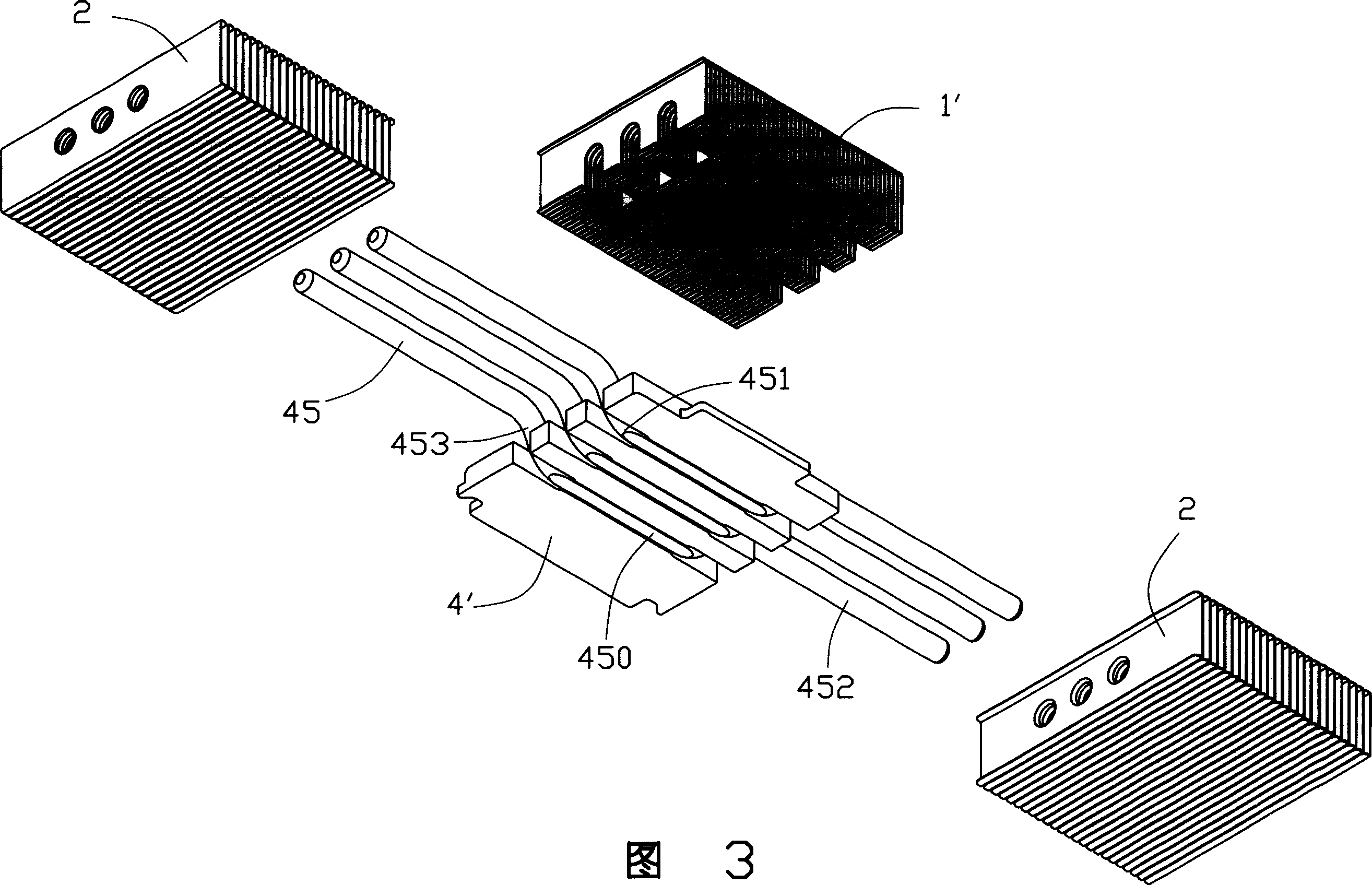

[0013] refer to Figure 1 to Figure 2 , The heat pipe cooling device of the present invention includes two cooling fin groups 1 and 2, a substrate 4 and a heat pipe 5.

[0014] The substrate 4 has an upper surface 43 and a lower surface 42 . The lower surface 42 defines a horizontal groove 40 . One end of the substrate 4 corresponds to the groove 40 and defines a notch 41 . The notch 41 communicates with the groove 40 .

[0015] The heat pipe 5 is cylindrical, and its inner section along the radial direction is circular. The heat pipe 5 includes an evaporating portion 51 , a condensing portion 52 and a bending portion 53 connecting the evaporating portion 51 and the condensing portion 52 . The outer circular surface of the evaporator 51 has a flat surface 510 that is in direct contact with the heating surface of the heat source. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com