Ultraviolet cleaner

A cleaning device and ultraviolet technology, applied in cleaning methods and utensils, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problems of high heating temperature, influence of processing objects, low UV illumination, etc., to achieve high cleaning cleanliness, increase Effects of Illumination and Ozone Concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

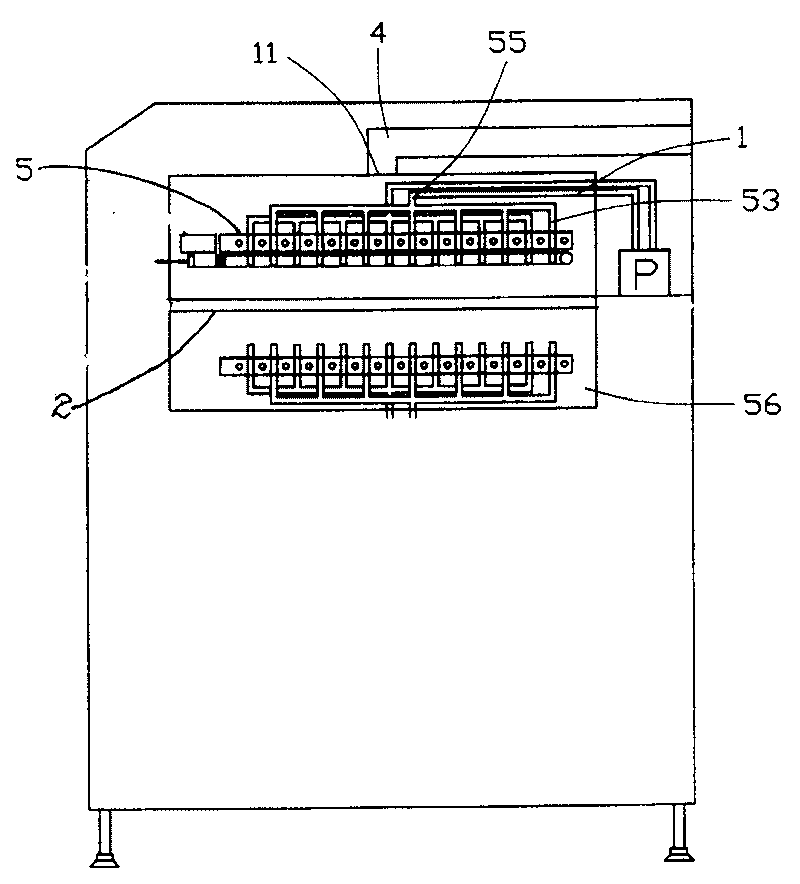

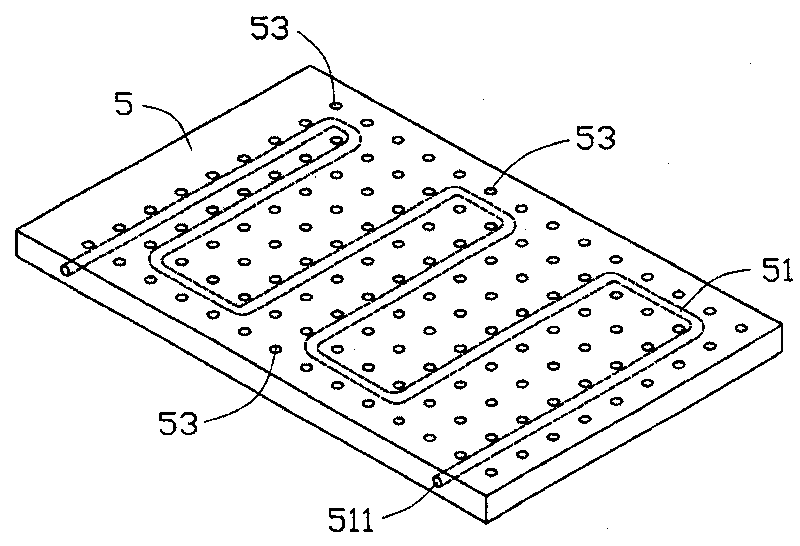

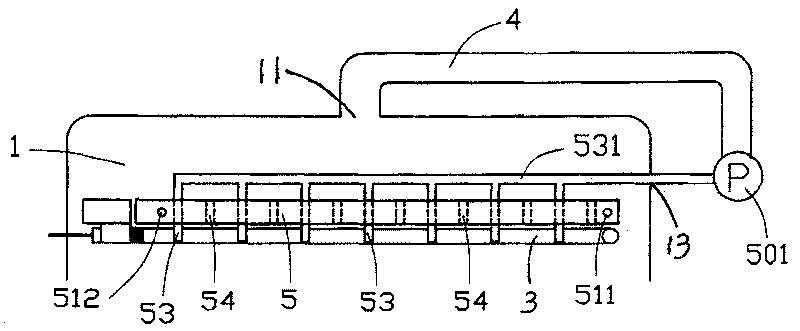

[0023] see figure 1 As shown, the ultraviolet cleaning device of the present invention is used for object surface cleaning and modification, including a reaction chamber 1, a workbench 2 that runs through the reaction chamber 1 for carrying workpieces, and has a plurality of ultraviolet discharge tubes 3 in the reaction chamber 1. 3 can simultaneously emit ultraviolet rays with wavelengths of 253.7 and 184.9NM, and their photon energies are 472KJ / mol and 647KJ / mol respectively, which can cut off most molecular bonds. The above-mentioned workbench 2 is a conveyor belt, which is driven by two runners. After the workpiece is placed on the workbench 2, the work enters the reaction chamber 1 due to the movement of the conveyor belt. In order to facilitate the entry and exit of the conveyor belt, openings are provided on both sides of the reaction chamber 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com