Intelligent control method for air compressor

An air compressor, intelligent control technology, applied in the direction of fluid pressure control, electrical program control, non-electric variable control, etc., can solve the problem of energy saving, unable to automatically adjust the operation stop, etc., to achieve stable and reliable measurement value, improve Service life, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

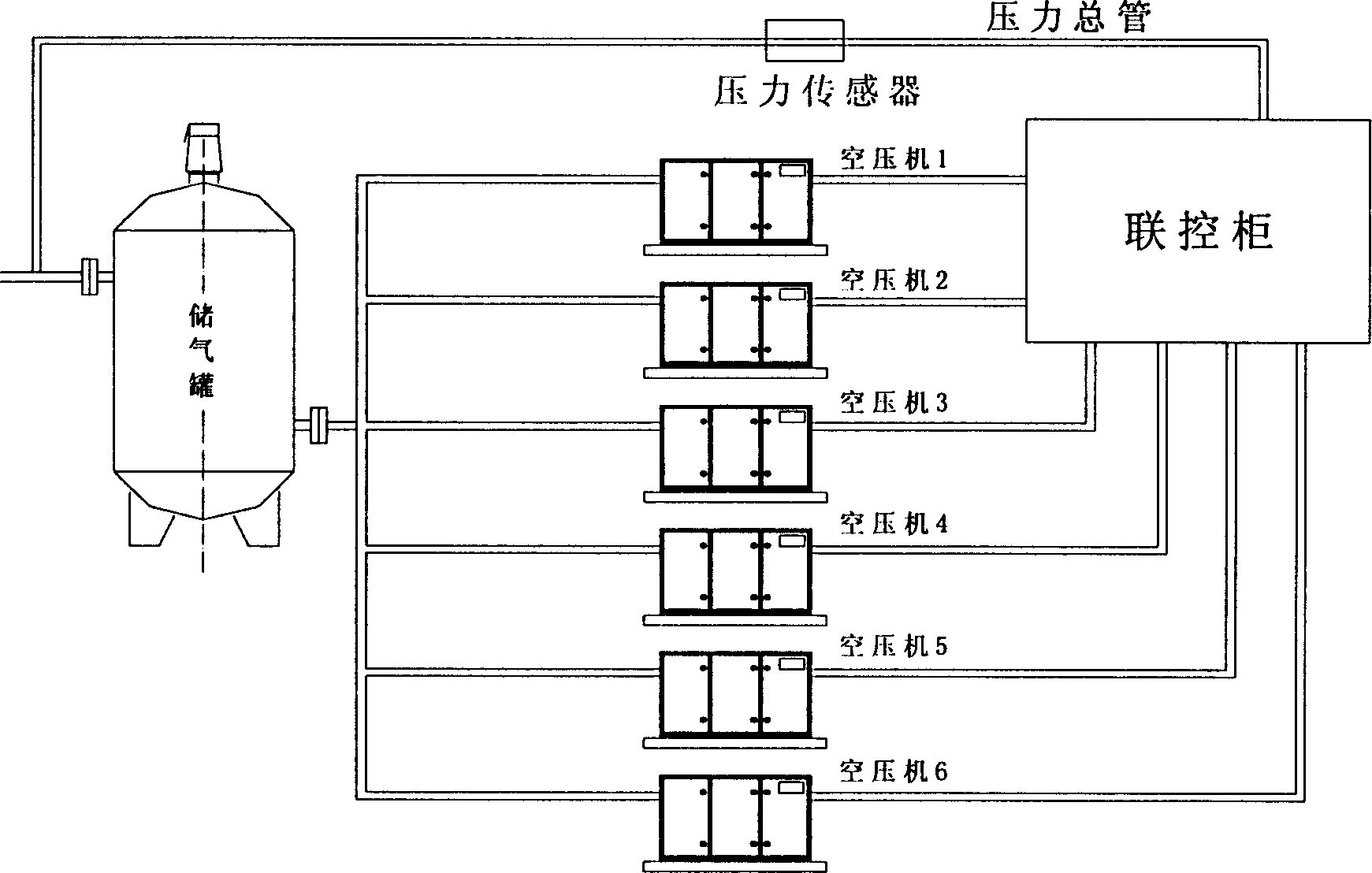

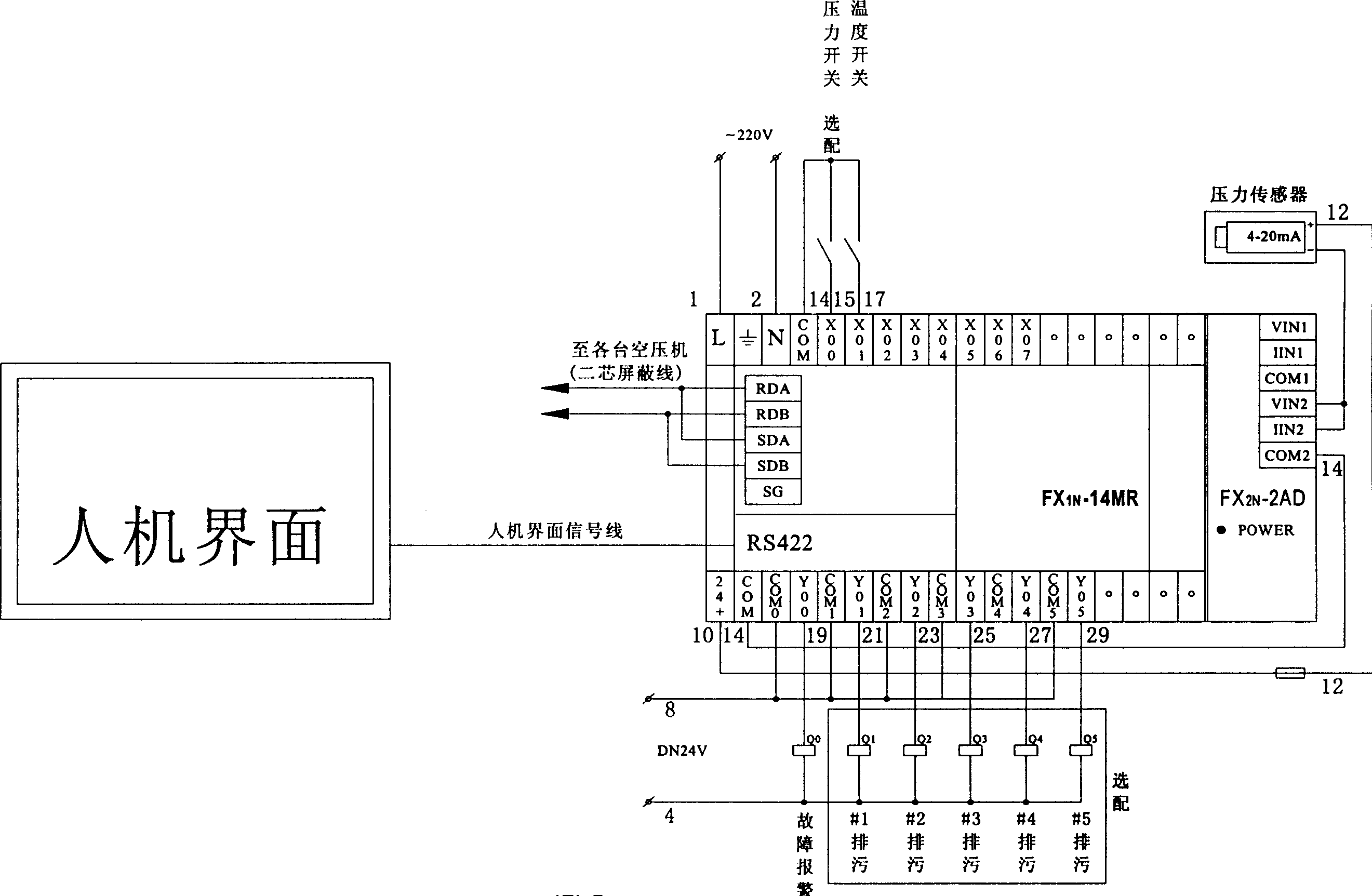

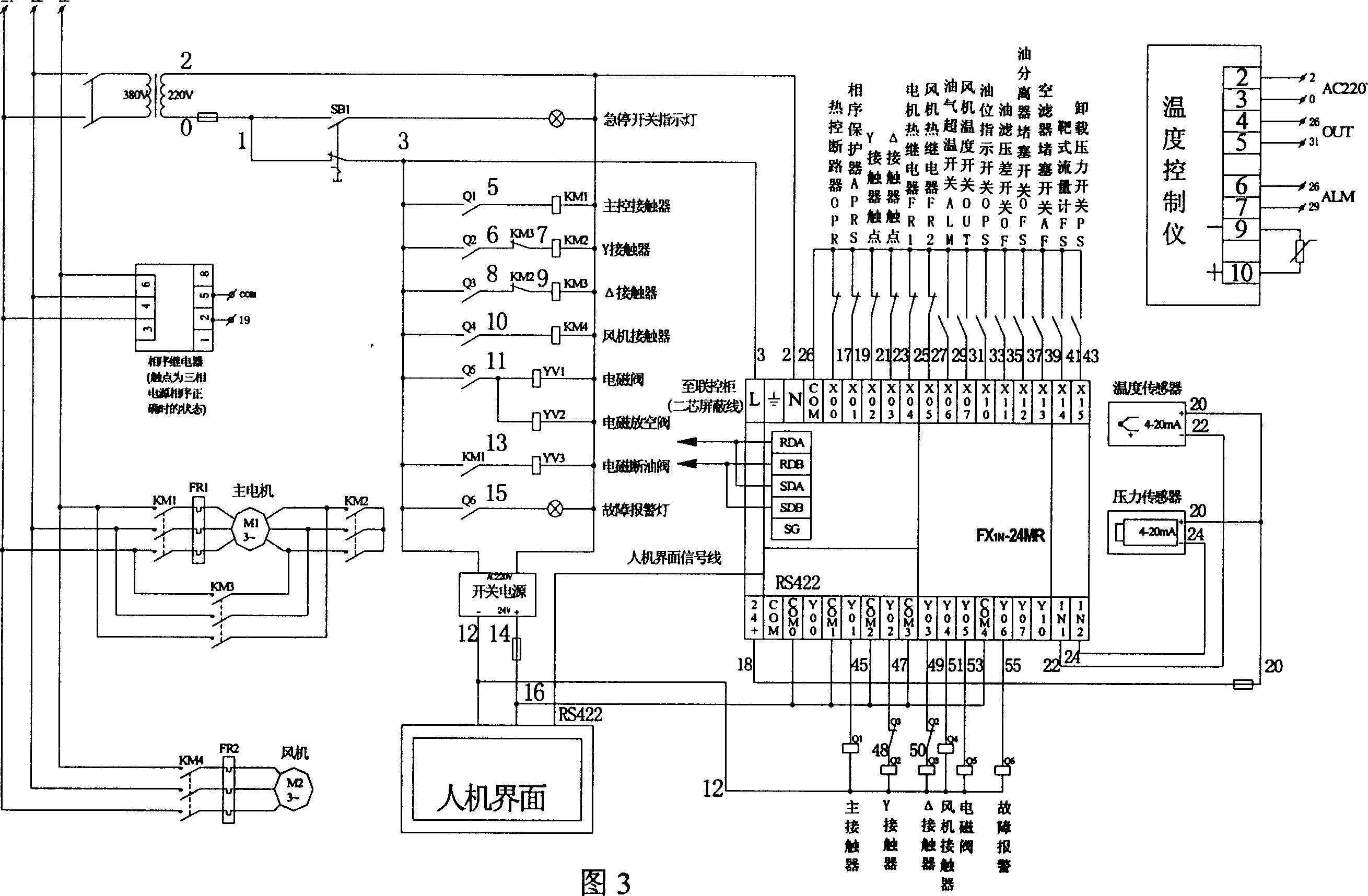

[0020] The hardware part involved in the present invention includes: a plurality of air compressors, each stand-alone electric control cabinet, a gas storage tank, a joint control cabinet for controlling each stand-alone work, a man-machine interface, a pressure pipeline and a cooling system, and the pressure pipeline includes and The pressure main pipe connected to the joint control cabinet and the pressure pipes of each single machine connected to the pressure main pipe, figure 1 A schematic diagram of the system including the control cabinet, stand-alone unit, gas storage tank, pressure manifold and pressure sensor is shown. There is a pressure sensor between the joint control cabinet and the pressure main pipe. The joint control cabinet and each stand-alone machine include a PLC controller, a communication interface and a switch input and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com