Method and apparatus for producing a lamp

一种挤压装置、灯管的技术,应用在冷阴极制造、电极系统制造、放电管/灯的制造等方向,能够解决费用昂贵、阴影和干扰等问题,达到改善正面照明、制造简化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

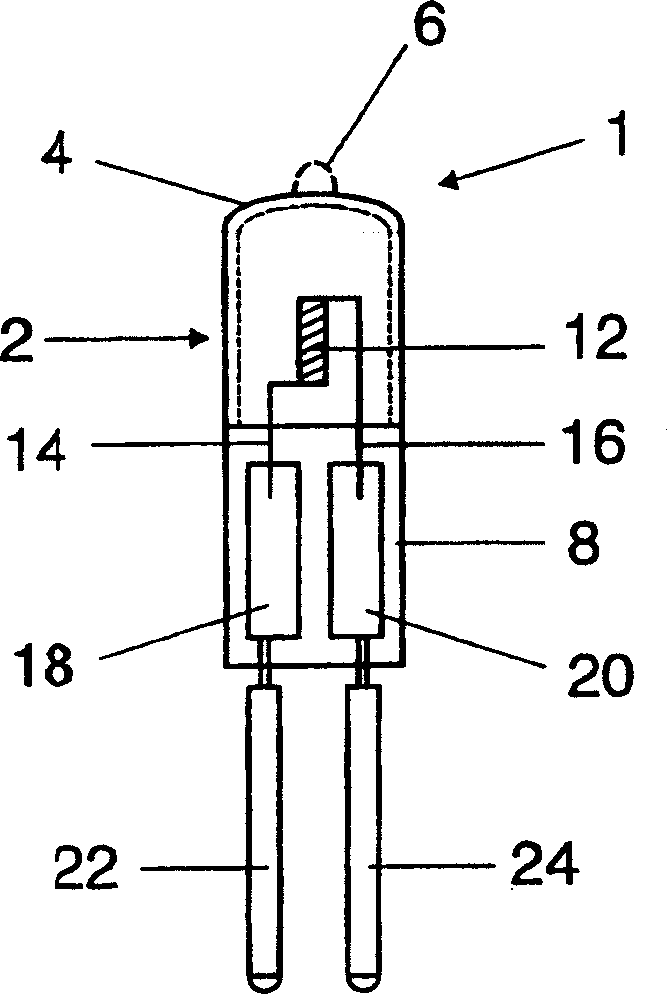

[0024] The invention is described below with the aid of a low-voltage halogen incandescent lamp. As already mentioned at the outset, the method according to the invention and the device according to the invention are by no means restricted to the application of these lamp types, and are only given here as examples.

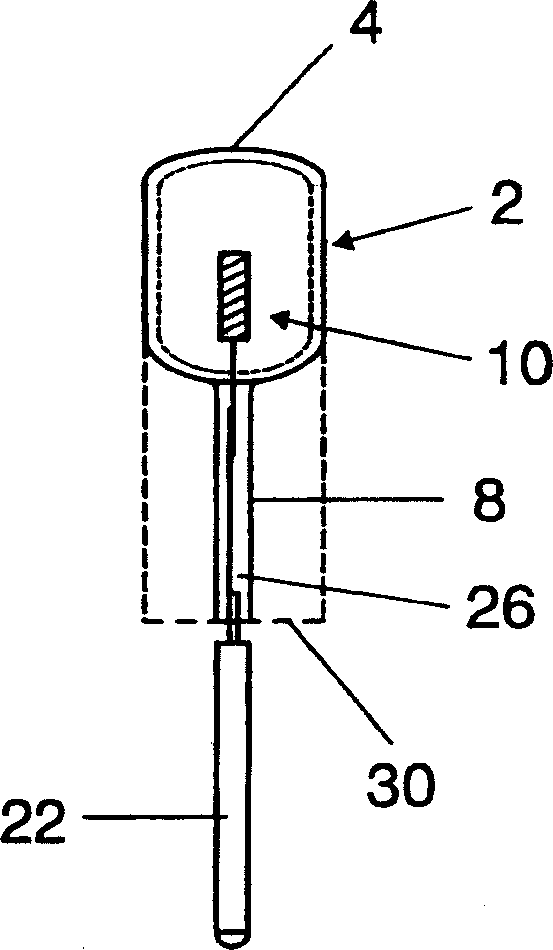

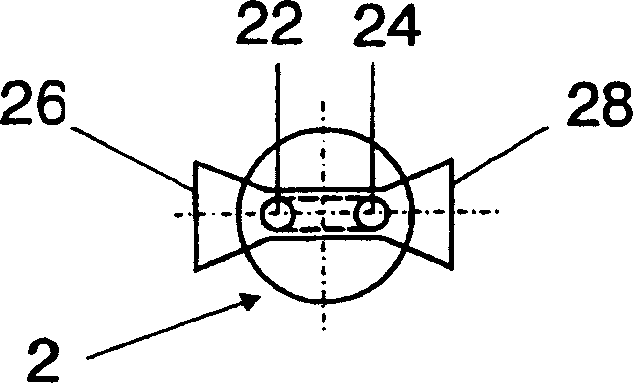

[0025] Figure 1 to 3 An embodiment of a halogen incandescent lamp is shown. The halogen incandescent lamp can be configured in a low-voltage working mode or grid voltage, and can be used in a living room or as a lamp in furniture.

[0026] The incandescent lamp 1 has a lamp tube shell 2, and the lamp tube shell 2 is in an initial state ( figure 2 Shown in dashed lines) has an approximately hollow cylindrical shape with the end formed by a spherically curved tip 4. Unlike traditional halogen incandescent lamps, it does not figure 1 The suction tip 6 shown in dashed lines in the middle forms a smooth plane, which does not hinder the reflection of the end surface. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com