Distribution-feedback single-longitudinal mode optical-fiber laser

A fiber laser and distributed feedback technology, applied in the direction of the structure/shape of the active medium, can solve the problems of high operating cost, high temperature regulation and control system requirements, and adverse effects on the performance of other devices around the DFB laser, etc., to achieve wavelength stability Good performance, stable and reliable repeatability, high precision effect

Inactive Publication Date: 2005-12-21

SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

View PDF0 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

And the temperature range of 100 degrees Celsius, if it is necessary to work stably in the low temperature area (less than -30 degrees Celsius) for a long time, the requirements for the temperature adjustment and control system are very high, and the operating cost is high

However, the operating temperature higher than 50 degrees Celsius will have an adverse effect on the characteristics of the DFB laser and the performance of other surrounding devices.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0026] The difference between embodiment 2 and embodiment 1 is that the DFB fiber laser 6 is an erbium-doped DFB fiber laser. Its technical effect is the same as above, its application range is wider, and it has more practical value.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

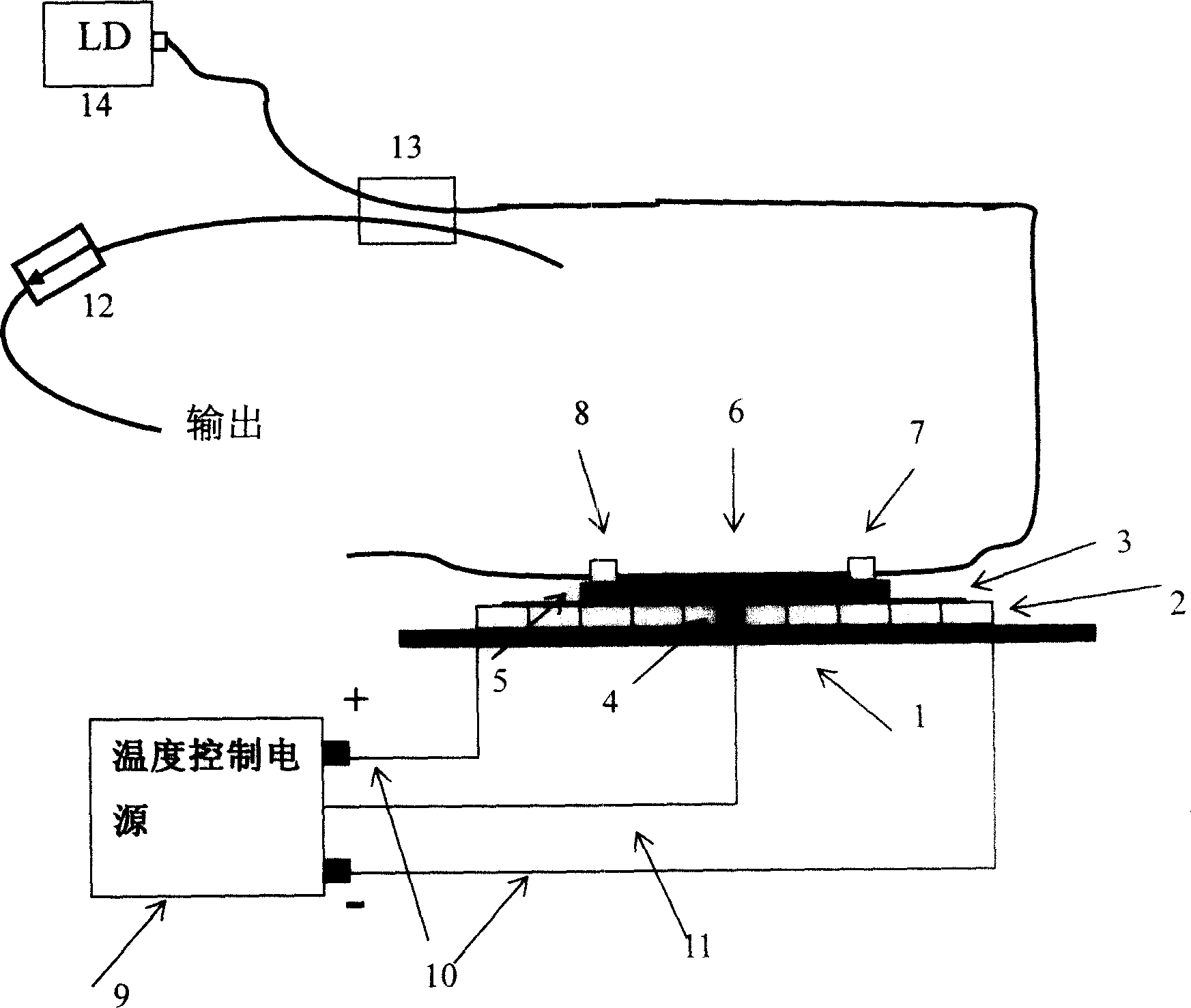

Structure of the disclosed fiber laser in single longitudinal mode including a DFB fiber laser is as following: two ends of DFB fiber laser are fixed on a thin metal plate through ultraviolet silica gel; the metal plate is placed on semiconductive ceramic chip, and a layer of conductive silica gel is between the metal plate and ceramic chip; the semiconductive ceramic chip is placed on a cooling plate; through a thermal resistor, the metal plate is connected to control pole of temperature control power source; through two pieces of conducting wire, two ends of the semiconductive ceramic chip are connected to two poles of temperature control power source. Except temperature control power source, each part said above is packaged in a thermal shield. Through a wavelength division multiplexer (WDM), one end of DFB fiber laser is extended out the shield to connect to a laser pump. Through a fiber optic isolater, third end of WDM constitutes output end of the disclosed laser.

Description

technical field [0001] The invention relates to a fiber laser, in particular to a stable operation tunable Distributed feedback of phase shift—distributed feedback (DFB) single longitudinal mode fiber laser. The laser can be used as the main oscillator in the front-end system of the inertial confinement nuclear fusion laser driver, and can be used in optical fiber sensors and spectral analysis devices. Background technique [0002] Write a grating on a Yb-doped fiber (ytterbium) to obtain a Yb-doped fiber DFB laser. Generated at the geometric center of the uniformly written DFB laser phase shift, a single longitudinal mode fiber laser is produced. The wavelength of such lasers can be determined by: [0003] λ=2nΛ [0004] Among them, λ is the operating wavelength of the DFB laser, n is the effective refractive index of the fiber, and ∧ is the grating period. Therefore, when the value of the grating period ∧ is changed, the operating wavelength of the DFB laser can be...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01S3/067

Inventor 陈柏陈嘉琳梁丽萍冯小星

Owner SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com