Fluidized-bed gasification furnace

A fluidized bed gasifier and fluidized bed technology are applied in the field of fluidized bed gasifiers and can solve problems such as disadvantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

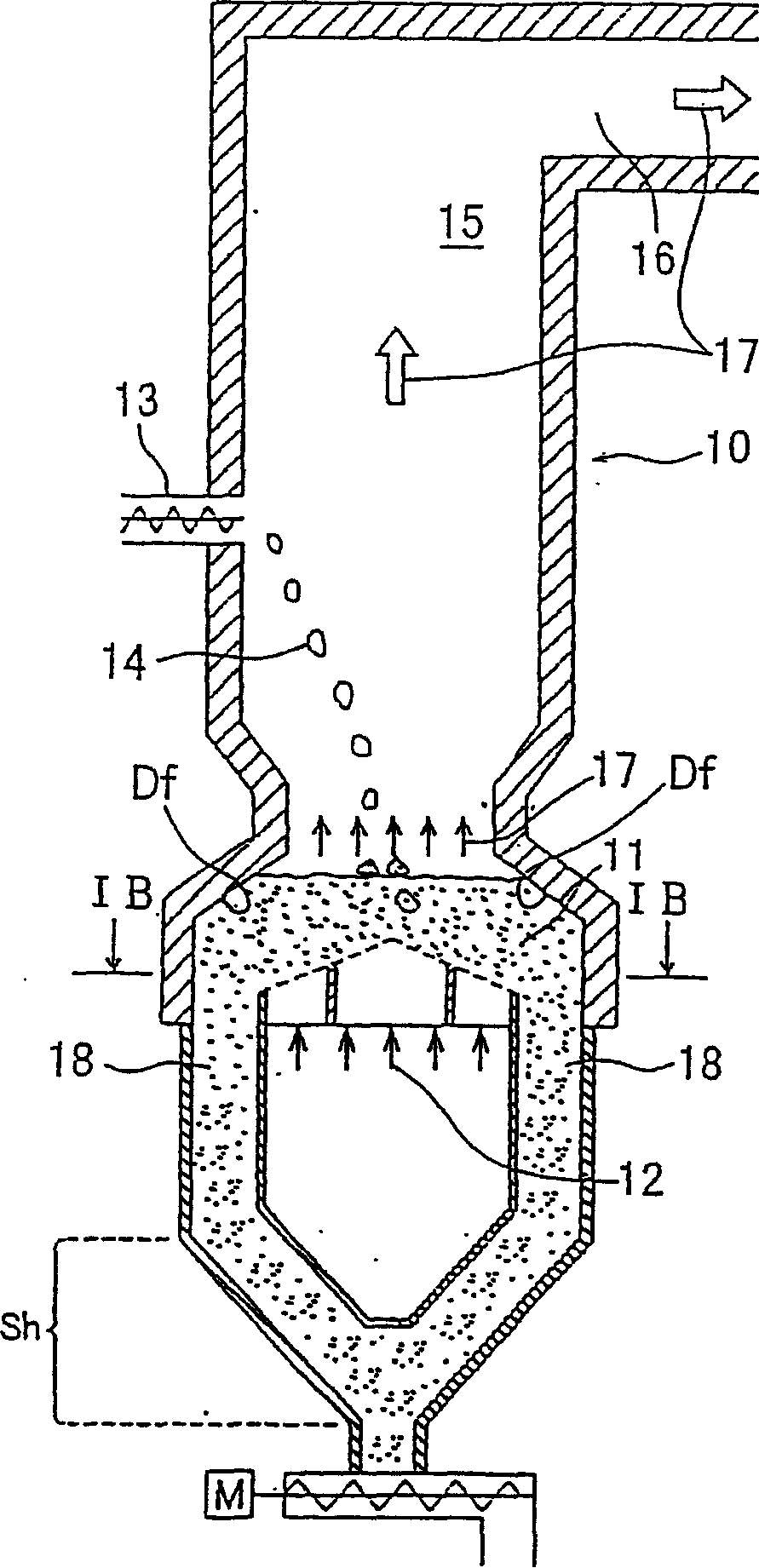

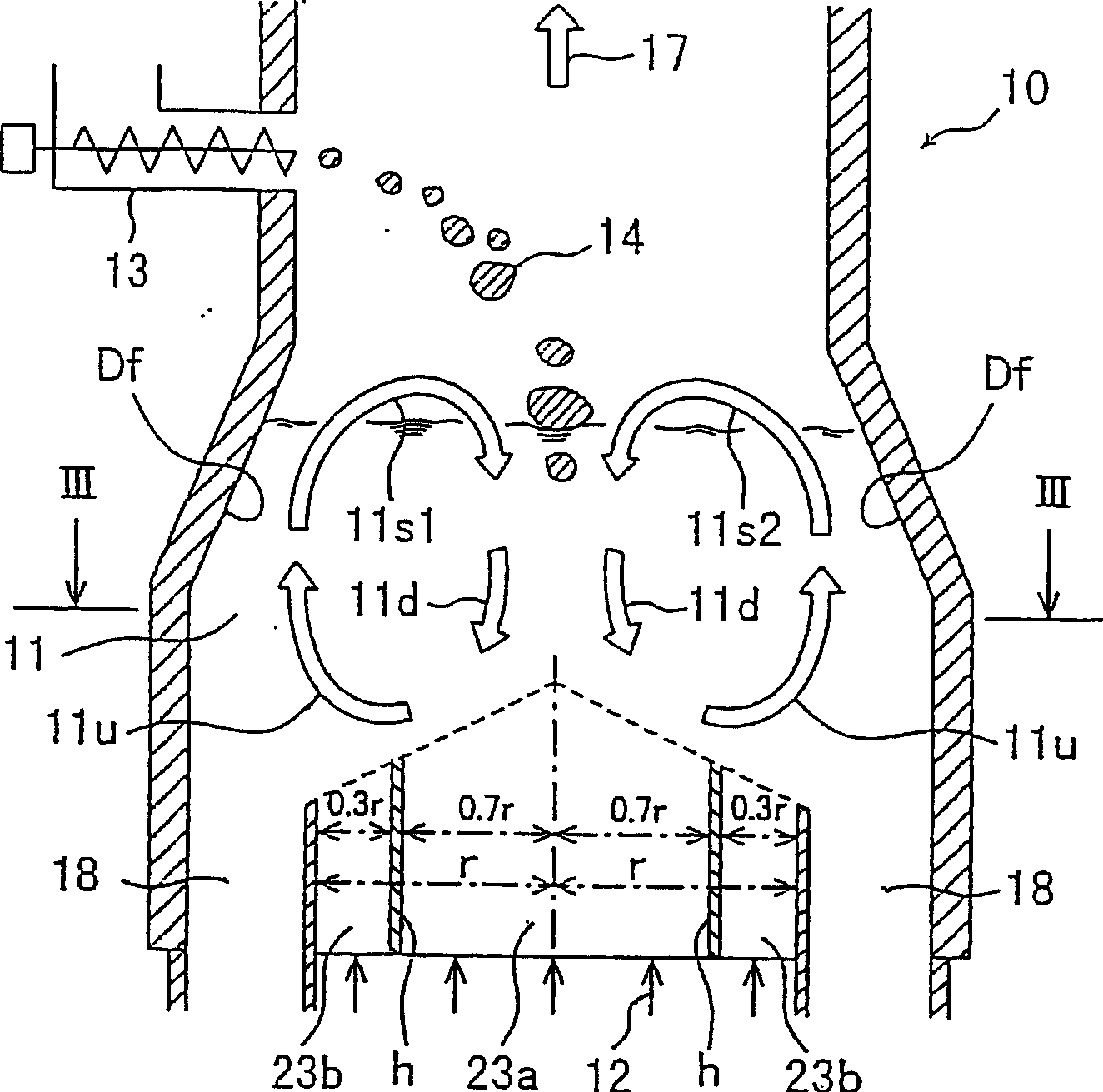

[0072] A fluidized bed gasifier according to an embodiment of the present invention will be described in detail below with reference to the accompanying drawings. Embodiments of the present invention will be described in comparison with conventional structures.

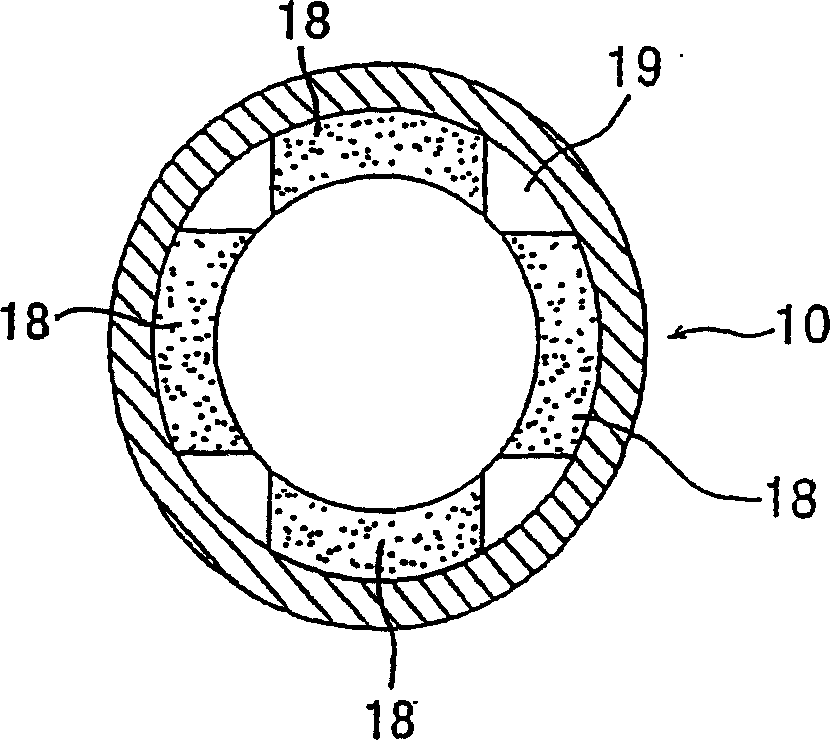

[0073] Figures 1A to 3 is a view of the overall structure of a conventional fluidized bed gasifier. Figure 1A is the vertical section view, Figure 1B along Figure 1A A cross-sectional view taken along the line IB-IB. figure 2 yes Figure 1A Magnified view of hearth area shown. image 3 is along figure 2 Sectional view taken on line III-III in

[0074] Such as Figures 1A to 3 As shown, a fluidized bed gasifier 10 has a fluidized bed 11 at its lower portion, in which a fluidizing medium such as silica sand is fluidized by introducing (ie, blowing) a fluidizing gas from the bottom of the fluidized bed gasifier 10 . In the fluidized bed (fluidized bed) 11, the descending fluidized bed 11d moving downward from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com