Apparatus for shaping double wall pipes with screw connections

A threaded connection, double-walled pipe technology, applied in the direction of threaded connection, pipeline connection layout, pipe/pipe joint/pipe fittings, etc., can solve the problems of large interface cost, polluted soil, aggravated engineering cost, etc., to achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

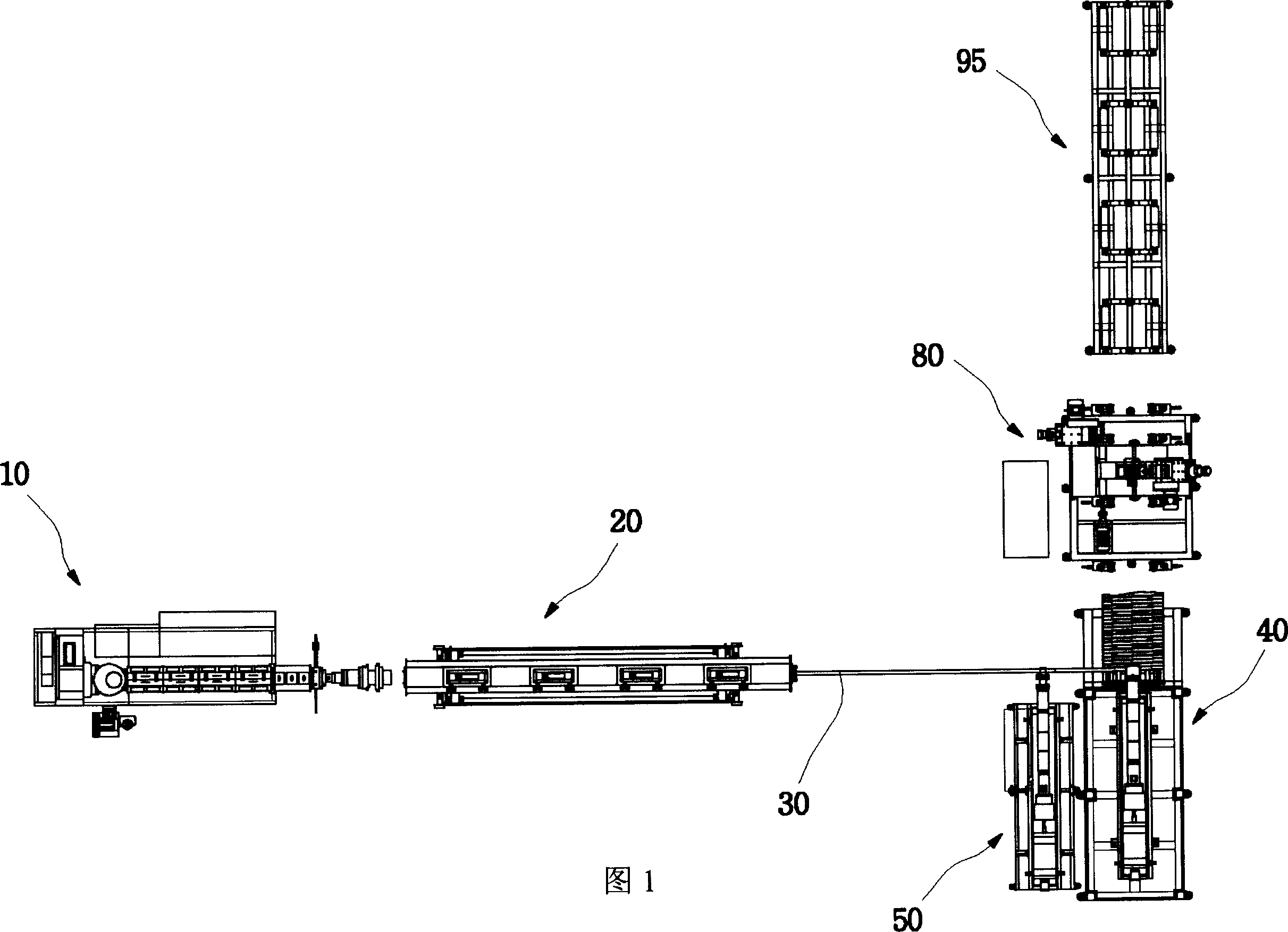

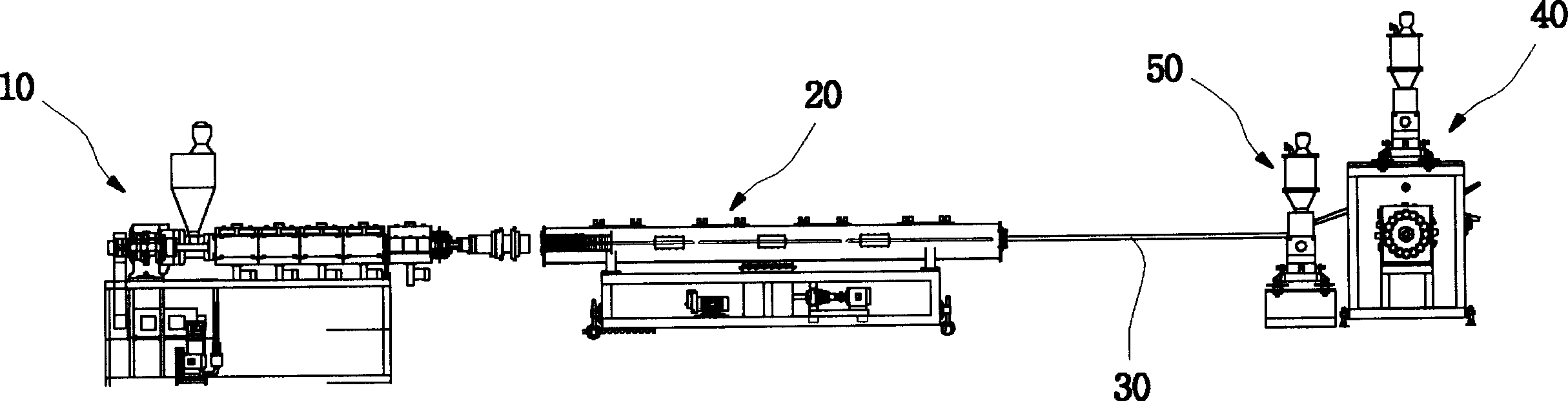

[0081] (1) Shape extrusion process

[0082] Through a pair of screws 11, the resin is melted and mixed to extrude a profile 30 with one or more central holes 31 inside.

[0083] During the above-mentioned extrusion process of the outer shape 30 , a reinforcing material such as the reinforcing duct 12 may be inserted inside the outer shape 30 .

[0084] (2) Cooling process

[0085] The extruded profile 30 is transferred to a cooling device 20 where it is cooled by a refrigerant or cold water.

[0086] At this time, the cooling device 20 is preferably maintained in a vacuum state.

[0087] (3) Shape transfer process

[0088] The cooled profile 30 is conveyed in a spiral to a hoist 41 provided on a duct forming device 40 .

[0089] (4) Inner wall covering process

[0090] The nozzle 51 of the inner wall covering extrusion device 50 covers the inner wall of the outer shape 30 with mainly yellow colored resin to form the inner diameter covering portion 52 , which forms the inn...

Embodiment approach 2

[0102] (1) Shape extrusion process

[0103] Through a pair of screws 11, the resin is melted and mixed to extrude a profile 30 with one or more central holes 31 inside.

[0104] (2) Cooling process

[0105] The extruded profile 30 is transferred to a cooling device 20 where it is cooled by a refrigerant or cold water.

[0106] At this time, the cooling device 20 is preferably maintained in a vacuum state.

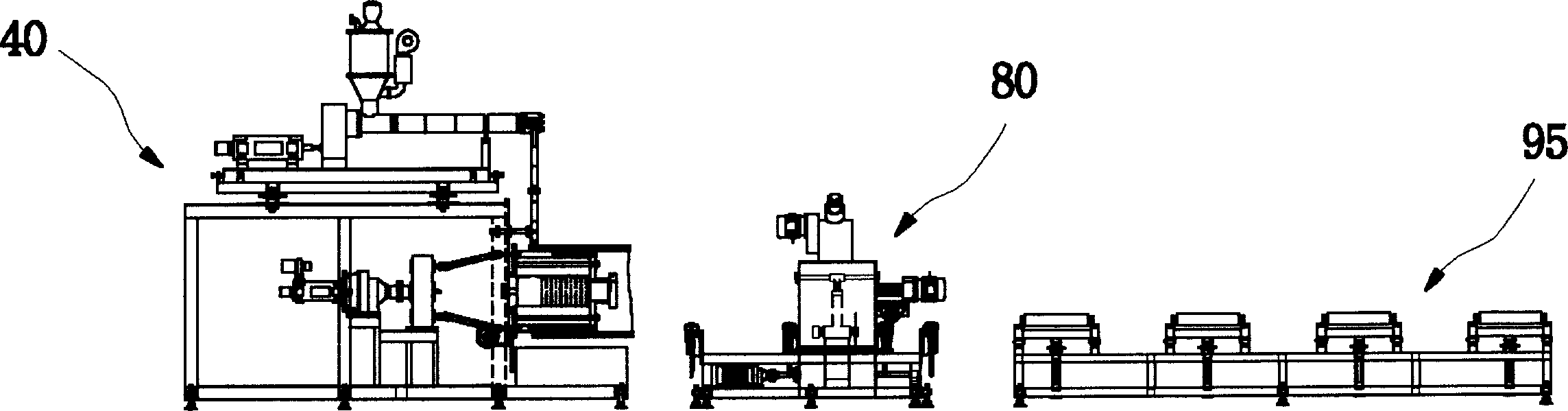

[0107] (3) Shape transfer process

[0108] The cooled profile 30 is conveyed in a spiral to the hoist 41 provided on the duct forming device 40

[0109] (5) hoisting process

[0110] The outer shape 30 forms the inner diameter covering part 52, and after forming the inner wall 71, when it is conveyed to the outside of the drum 42 of the winch 41 in a spiral shape, resin is supplied between the outer shapes 30 from the connection nozzle 61 connected to the extrusion device 60, and the outer shapes 30 are connected to each other to form a conduit. .

[0111] (6) Inner d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com