Method and arrangement in making of mechanical pulp

A mechanical pulping and pulping technology, applied in the regeneration of pulping liquid, textile and papermaking, fractionation/concentration of waste liquid, etc., to achieve the effect of improving cleanliness and reducing demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

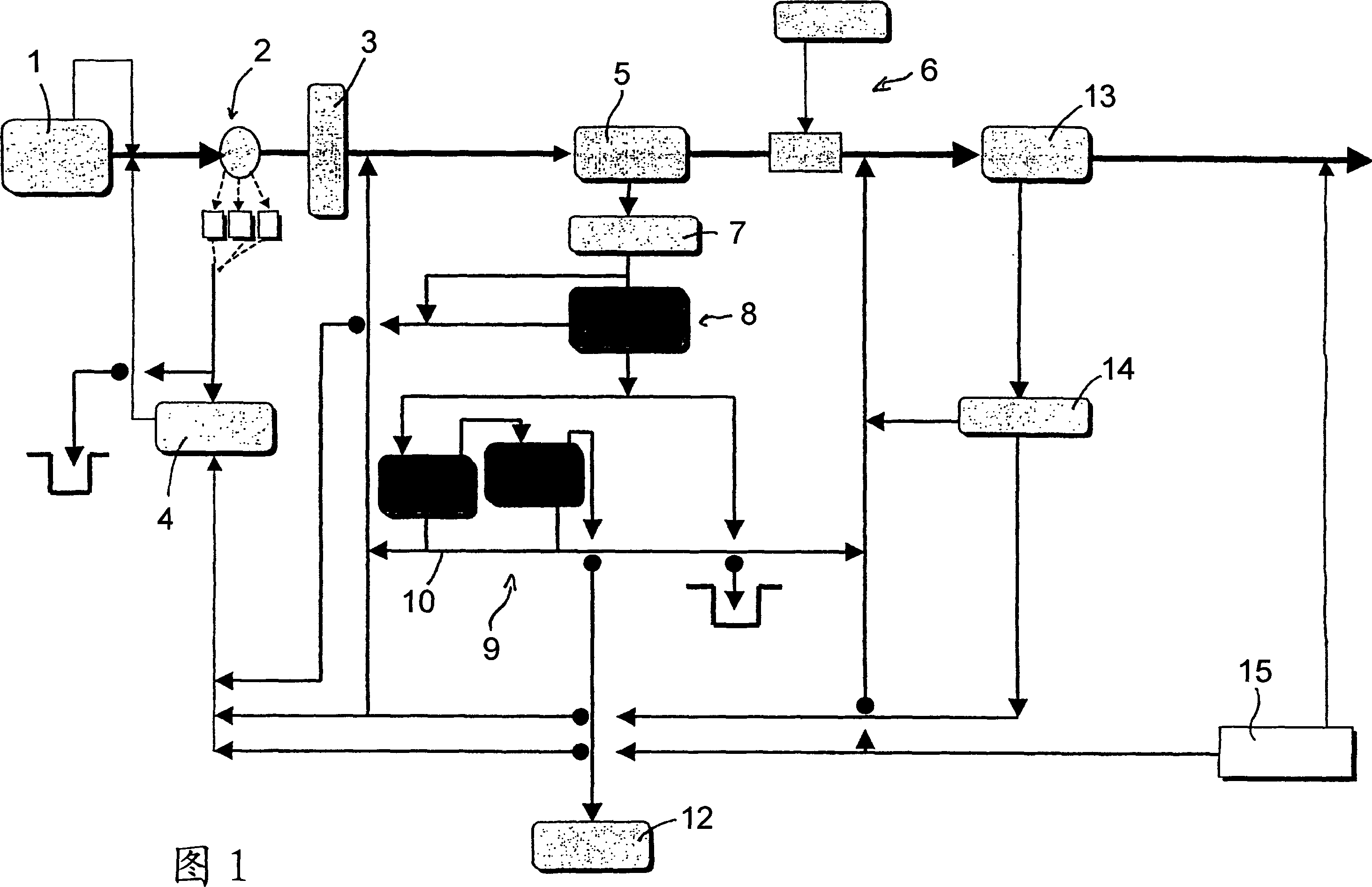

[0044] By way of an example, Figure 1 illustrates the pulping process schematically. As shown in Figure 1, pulp is produced from a mechanical pulp, ie, fiber separation, such as from a mill 1 or refiner, generally at a consistency of about 0.1% to 0.8%. The mechanical pulp preparation process used can be, for example, thermomechanical pulping (TMP), grinding (GW / SGW; groundwood / groundwood), pressure grinding (PGW: pressure groundwood) or thermal grinding ( TGW; thermal groundwood pulp). The mechanical pulping process can also be chemi-thermomechanical pulping (CTMP) or chemi-mechanical pulping (CMP), which do not use bleaching agents in refining. By defibration, the pulp is introduced into a thickening 2, for example into a disc filter. During the thickening step the consistency of the pulp is generally raised to about 6-12% and the pulp is generally directed to intermediate storage 3 . The thickened filtrate is introduced into the white water tank 4, from where it is led b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com