Heat sink module with sound silencing function

A heat dissipation module and functional technology, applied in the direction of instruments, electrical digital data processing, digital data processing components, etc., can solve the problems of fan wake disturbance, noise and heat dissipation, and achieve stable flow field, good sound quality, The effect of reducing the amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

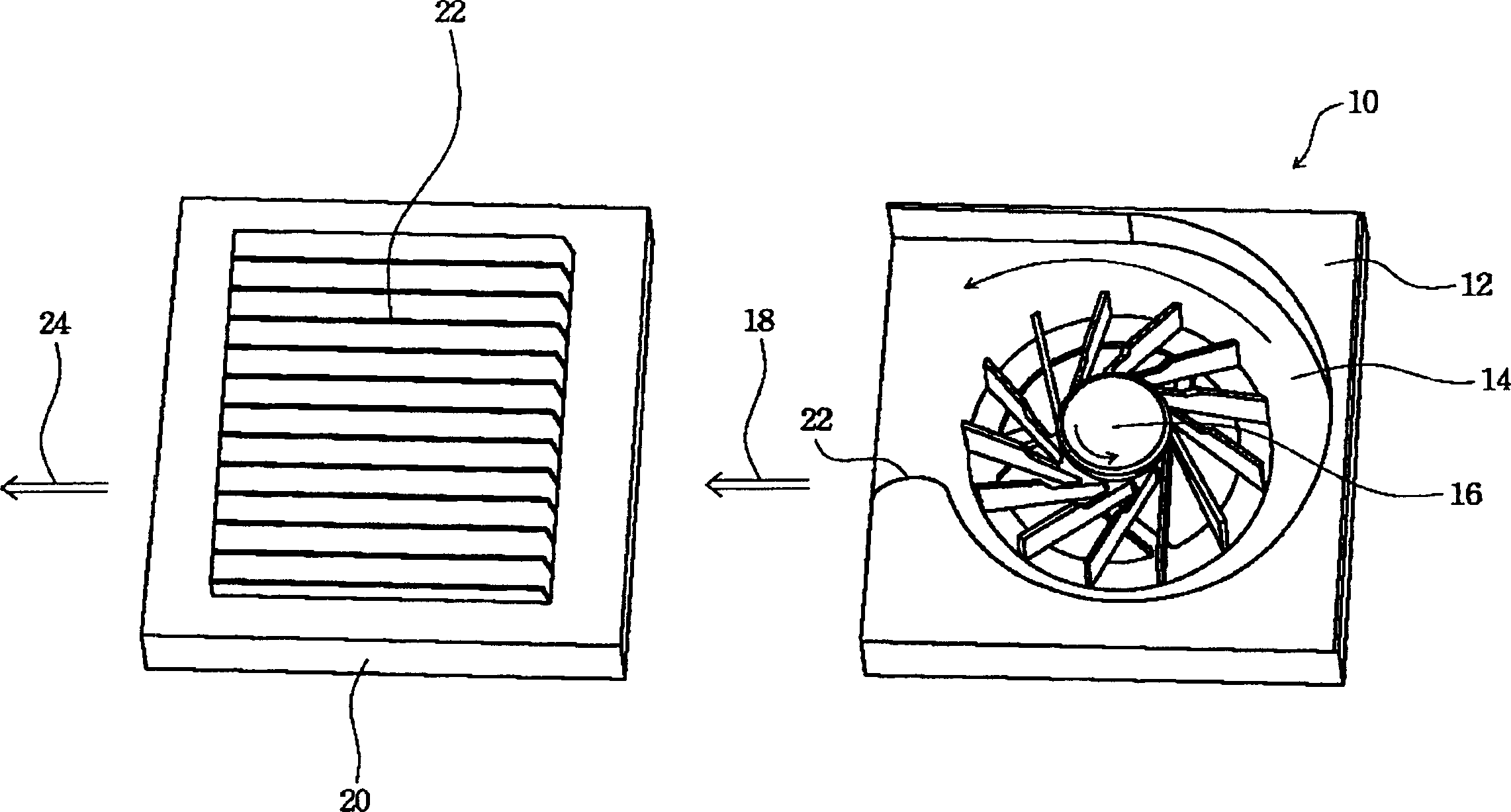

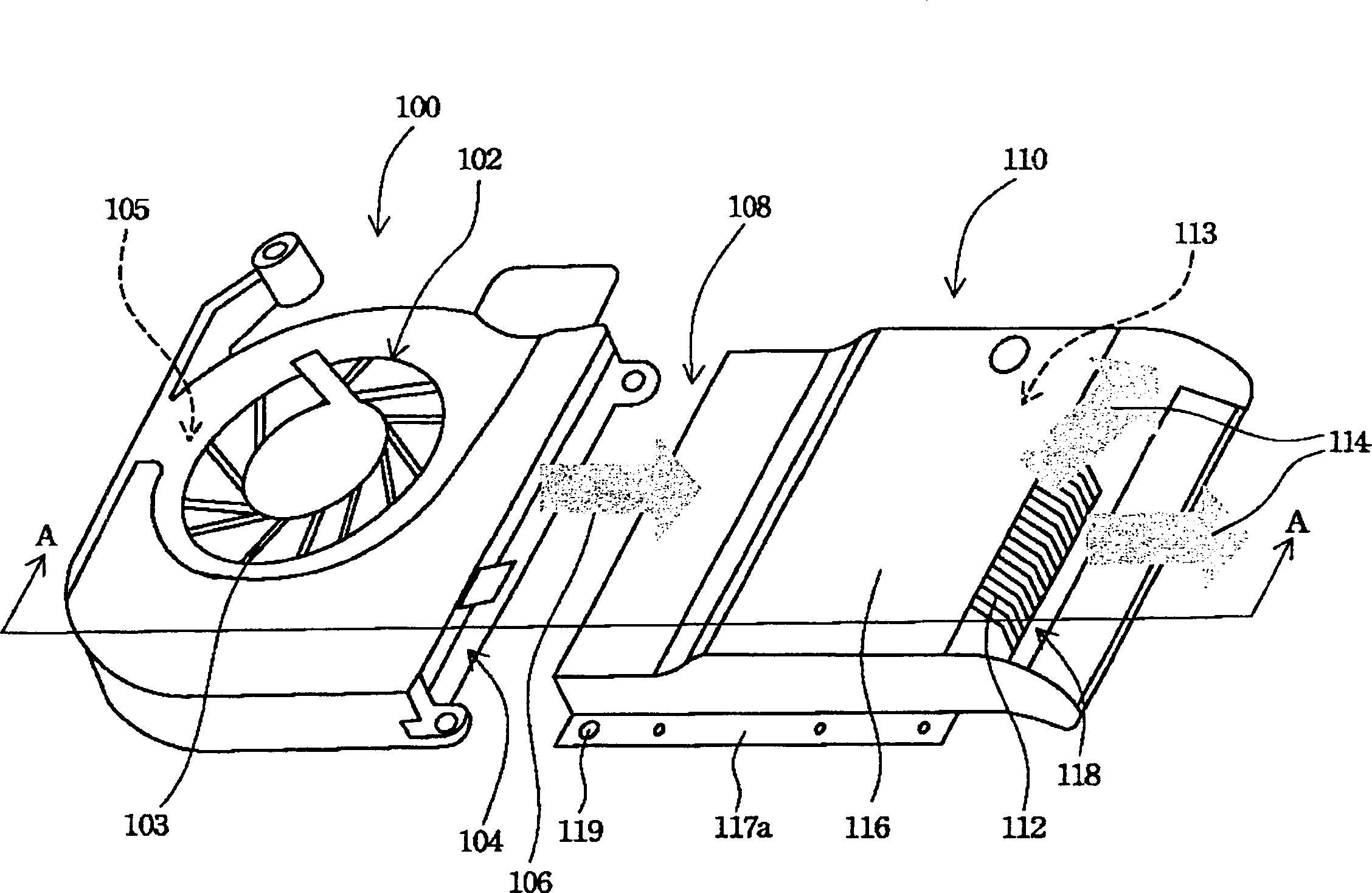

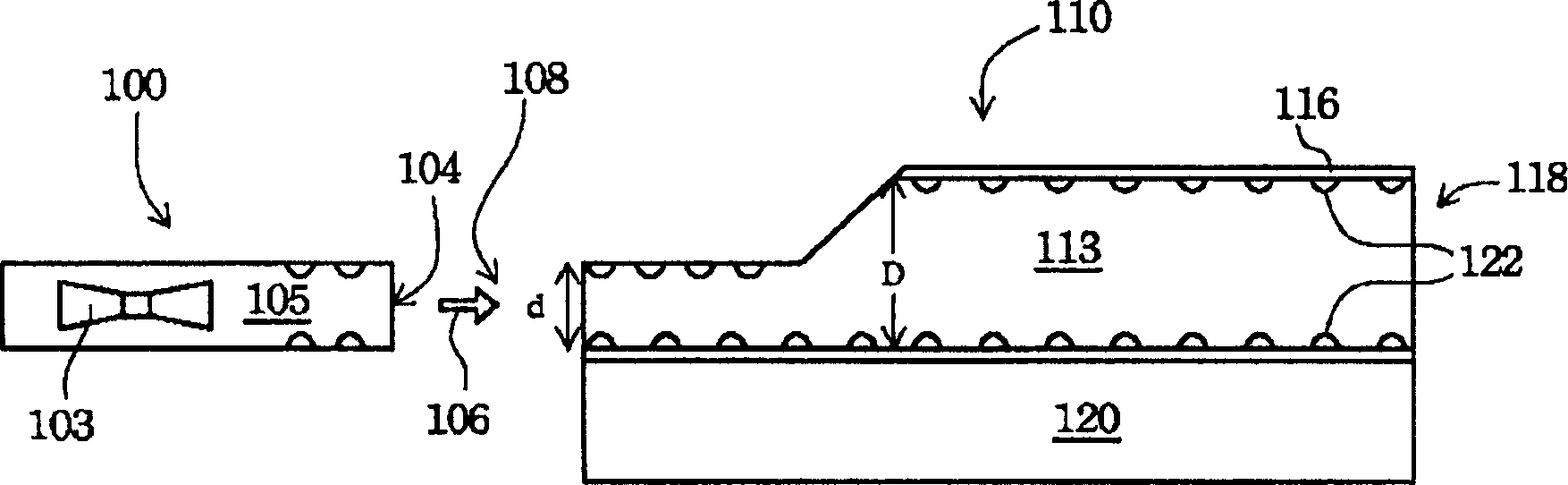

[0013] In order to solve the dilemma of noise and heat dissipation, the present invention proposes a heat dissipation module with a noise reduction function. In the present invention, an uneven structure is designed in the flow channel of the heat dissipation module (for example, the heat dissipation module of heat dissipation fins) to reduce noise.

[0014] Please refer to figure 2 , which shows a schematic diagram of a heat dissipation module with noise reduction function according to a preferred embodiment of the present invention. This embodiment includes a centrifugal fan 100 and a cooling fin module 110 . The centrifugal fan 100 has a centrifugal blade 103 . The motor (not shown) in the centrifugal fan 100 drives the centrifugal fan blade 103 , so that air is taken in through the air inlet 102 , passes through the volute channel 105 in the fan, and finally exits through the air outlet 104 . Due to the friction between the fluid and the tube wall in the spiral channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com