Making method of paper for furniture and construction material and its product

A manufacturing method and technology of building materials, applied to crafts, paper, and papermaking for producing decorative surface effects, which can solve problems such as changing colors or patterns, increasing manufacturing costs, and increasing processing time, so as to achieve simple manufacturing processes, The effect of good mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

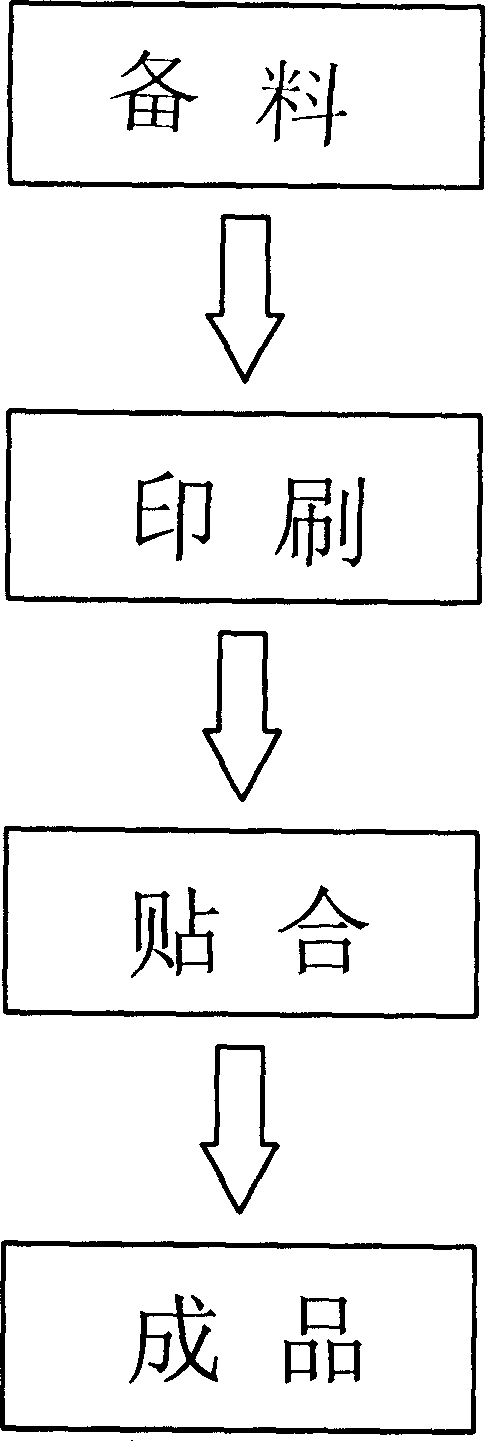

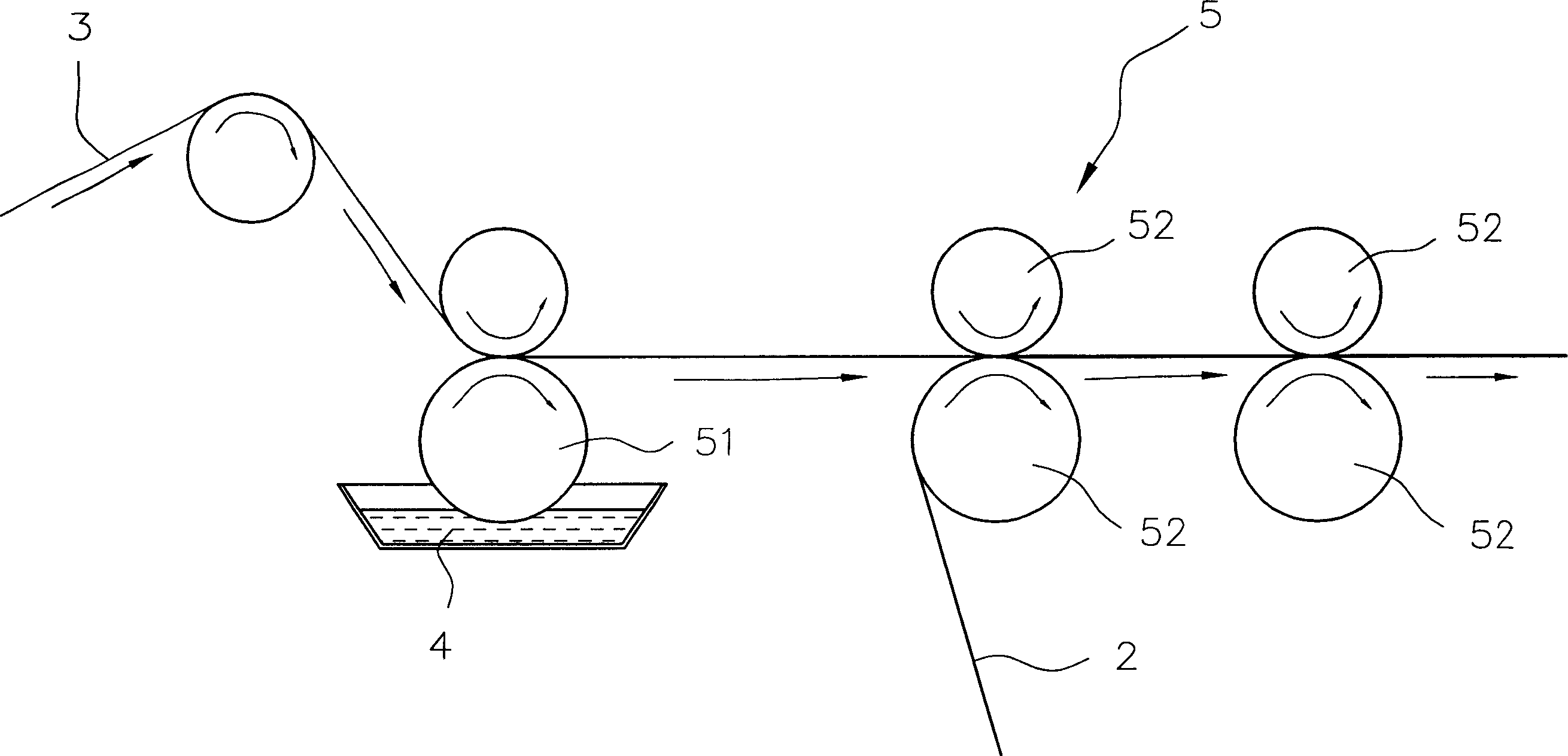

Method used

Image

Examples

Embodiment approach

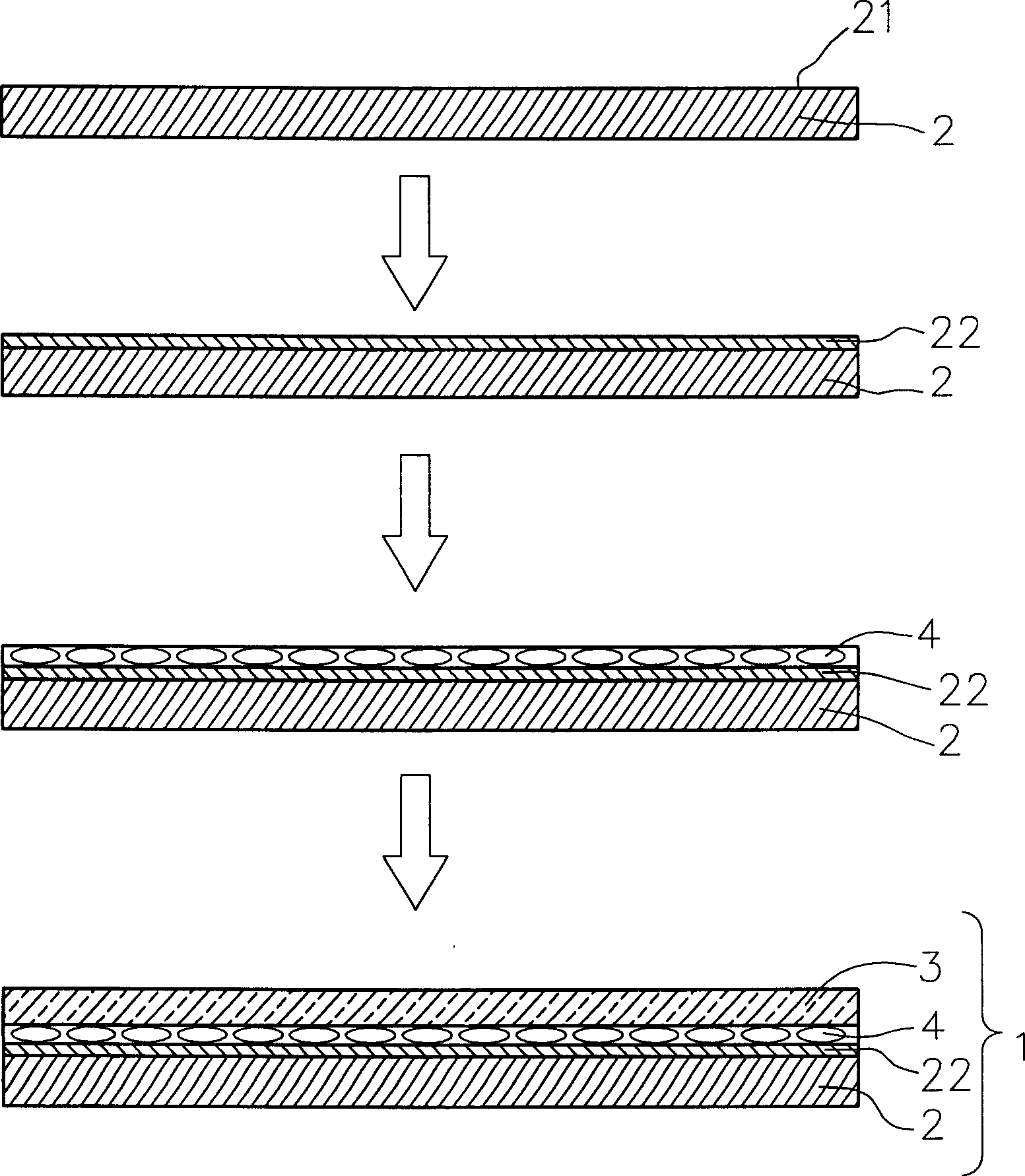

[0043] 1. During the production process of the adhesive film, add a flatting agent before the adhesive film is cured to control its atomization degree to produce a translucent adhesive film, and then attach the adhesive film to the printing layer of the backing paper, Make the paper for furniture and building materials present a matte effect.

[0044] 2. After selecting a transparent adhesive film and pasting it on the printing layer of the backing paper, then grind the surface of the adhesive film to control the degree of atomization of the adhesive film, so that the furniture and building materials paper presents a matte surface Effect.

[0045] see Figure 4 The product structure of paper for furniture and building materials can be obtained by the above steps, including a bottom paper 2, the bottom paper 2 has a printing surface 21, and a printing layer 22 is printed on the surface of the printing surface 21, and the printing layer 22 is opposite to the bottom paper. One si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com