Automatic shearing machine

A cutting machine and automatic technology, applied in metal processing, etc., can solve the problems of large space occupation, high price, complex positioning structure and control structure, etc., and achieve the effect of improving production efficiency and rapid material retrieving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

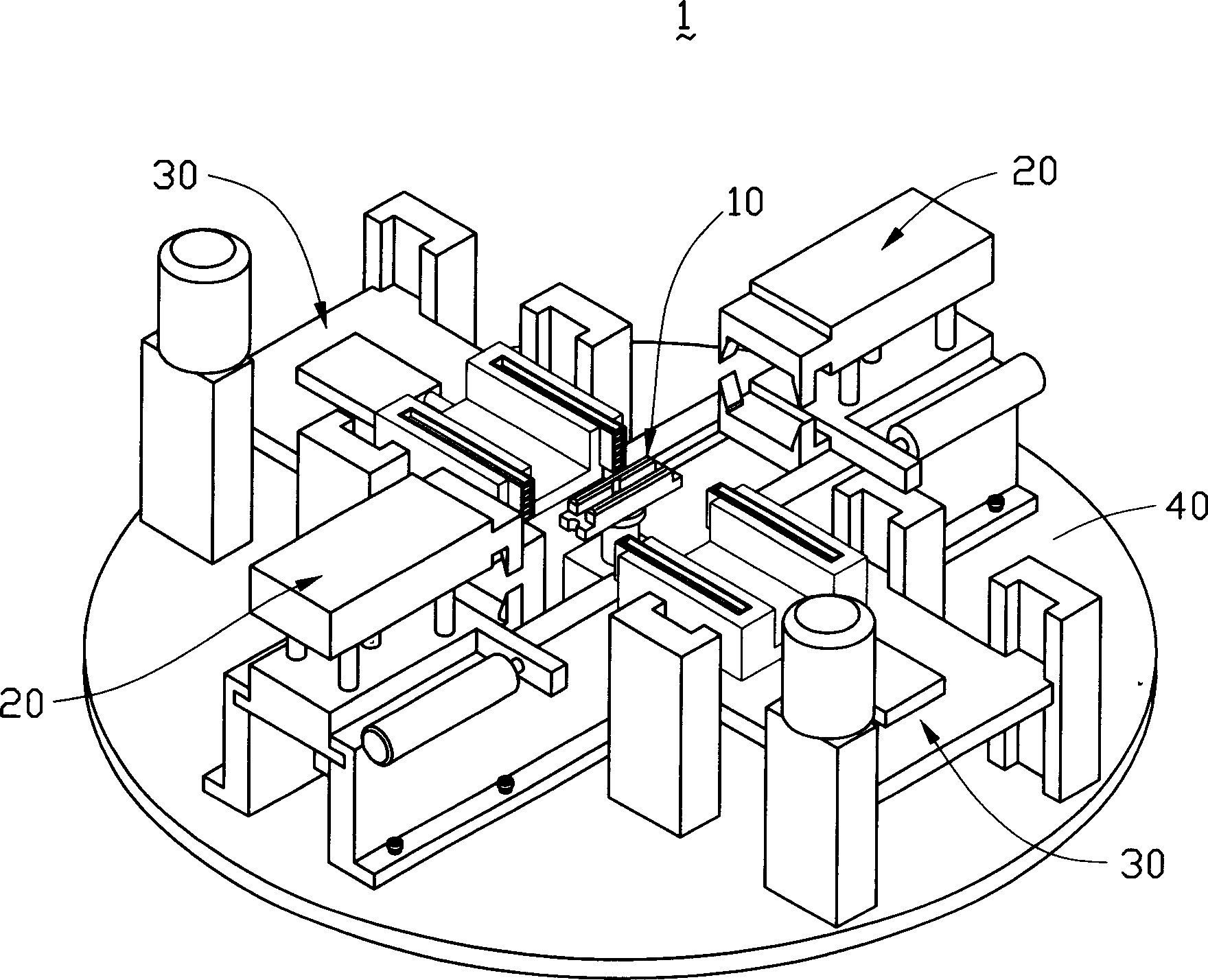

[0032] Please refer to figure 2 As shown, the automatic shearing machine 1 of the present invention at least includes a material receiving mechanism 10, a shearing mechanism 20, a material retrieving mechanism 30, a main part carrying these mechanisms, and an electrical control part that can control the actions of these mechanisms, wherein the main part includes organic Seat 40, electric box and other auxiliary equipment etc., and the electrical control part is mainly made of programmable controller, relay and other auxiliary circuits. Because the focus of the invention of the automatic shearing machine 1 of the present invention is: the integrated structure and shearing method of the material receiving mechanism 10, the shearing mechanism 20 and the material taking mechanism 30, and some other existing components, such as auxiliary equipment etc., will no longer Details.

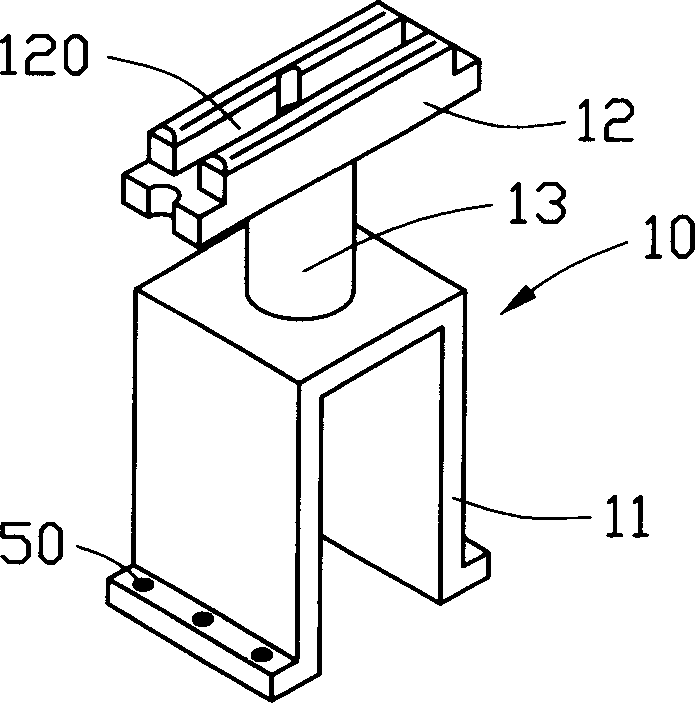

[0033] Such as Figure 3A and Figure 3BAs shown, the material receiving mechanism 10 mainly include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com