Fluidized production process for granular calcium chloride

A calcium chloride, fluidized technology, applied in the direction of calcium/strontium/barium chloride, calcium/strontium/barium halide, etc., can solve the problem that granular calcium chloride does not have a large area of promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

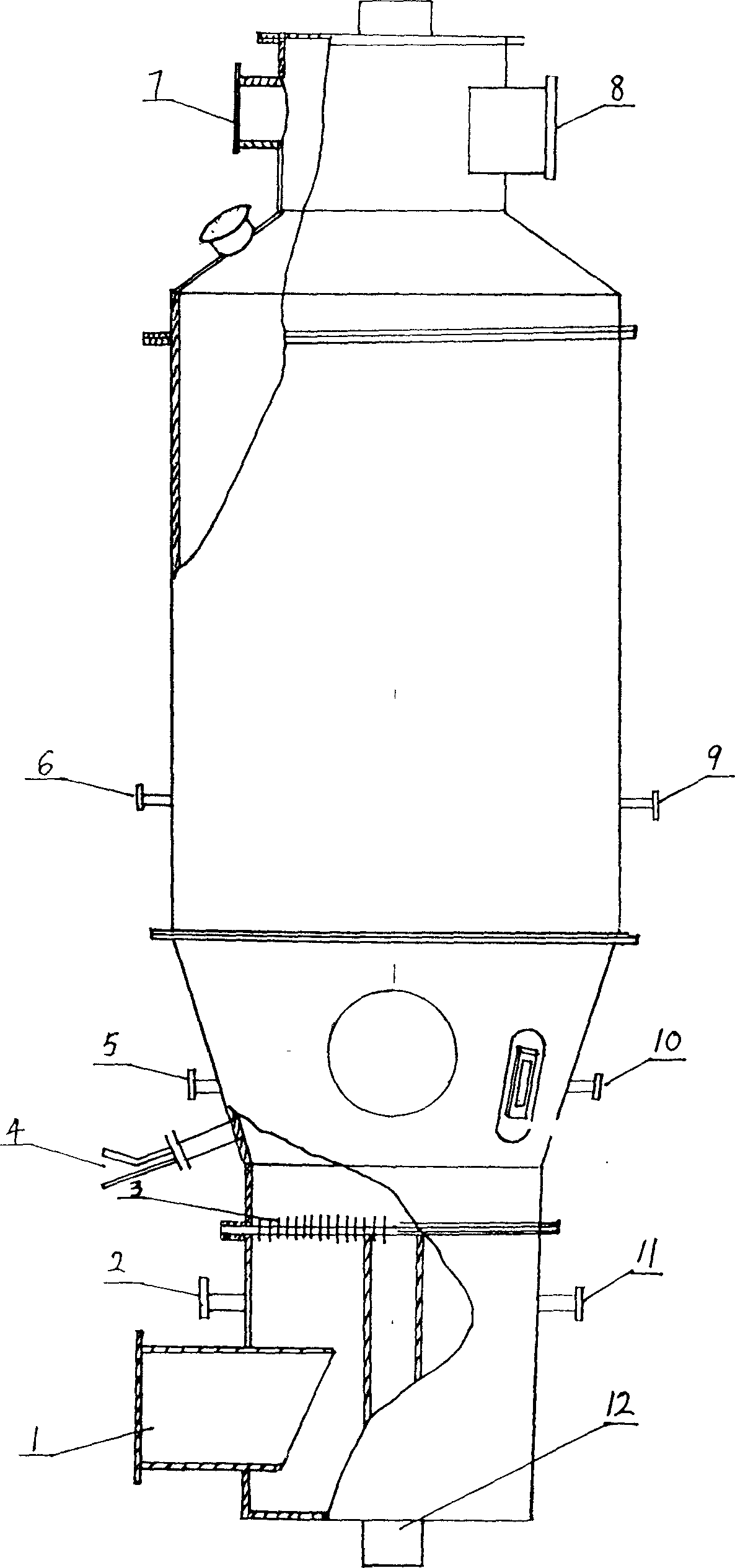

[0015] The lower part of the boiling granulation tower is the boiling section, which is an inverted cone-shaped cylinder. The lower part is an air distribution orifice plate 3, the upper part of the orifice plate is the boiling layer, and the lower part of the orifice plate has a high-temperature hot gas inlet 1. Material tube 12.

[0016] The process parameters are:

[0017] (1) The temperature of high temperature hot air under the orifice plate is 380-420°C

[0018] (2) Boiling section temperature 170-200°C

[0019] (3) Tower body temperature 160-190°C

[0020] (4) Under the orifice plate - pressure difference in boiling section (pressure difference between pressure measuring port 2 and pressure measuring port 5)

[0021] 380-420mmH 2 o

[0022] (5) Negative pressure in boiling section -30mmH 2 o

[0023] (6) Liquid calcium chloride is atomized by compressed air through the nozzle, and the air pressure is 0.2-0.5Mpa

[0024] ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap