Fe-based amorphous alloy ribbon

A technology of amorphous alloys and atoms, applied in the field of Fe-based amorphous alloy strips, which can solve the problems of brittle strips, inability to stably produce Fe-based amorphous alloy strips, surface crystallization and thermal stability decline, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

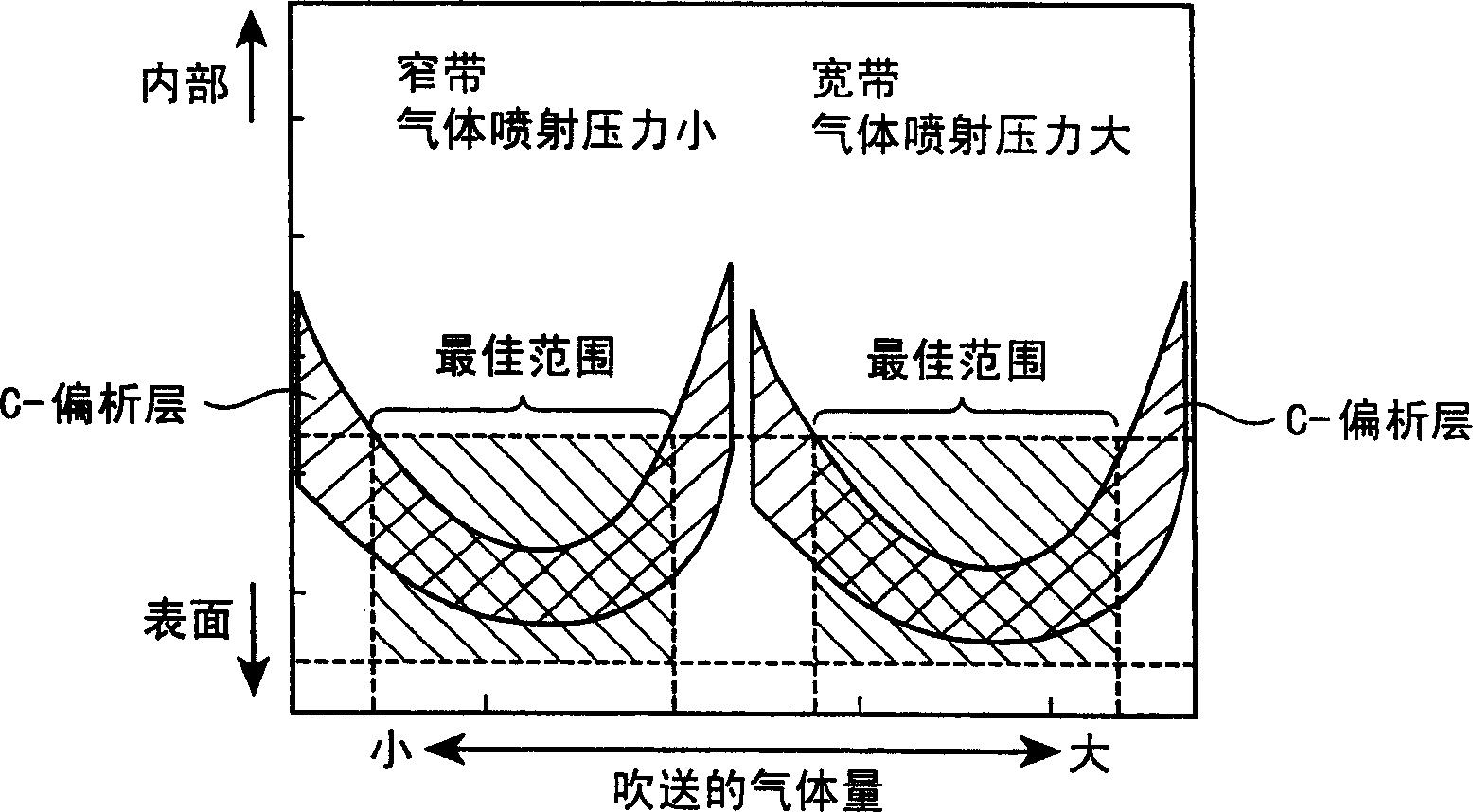

[0033] Composition of 200g as Fe 82 Si 2 B 14 C 2 The alloy is melted in a high-frequency electric furnace and sprayed through the furnace nozzle onto a copper roll rotating at 25 to 30m / s, while CO is blown from behind the nozzle 2 gas to produce Fe-based amorphous alloy ribbons with widths of 5 mm, 10 mm, and 20 mm and thicknesses of 23 to 25 μm. Each Fe-based amorphous alloy ribbon has a C-segregation layer at a depth of 2 to 20 nm from the surface. To minimize core loss, the Fe-based amorphous alloy ribbon was annealed at 300 to 400 °C. Change blown CO 2 Gas velocity, the properties of Fe-based amorphous alloy ribbons were measured. The results are shown in Table 1.

[0034] Measure B on a monolithic sample S and B 80 , and measure the core loss W 13 / 50 and W 14 / 50 , where W 13 / 50 is the core loss at 1.3T magnetic flux density and 50Hz frequency, W 14 / 50 It is the core loss at 1.4T magnetic flux density and 50Hz frequency.

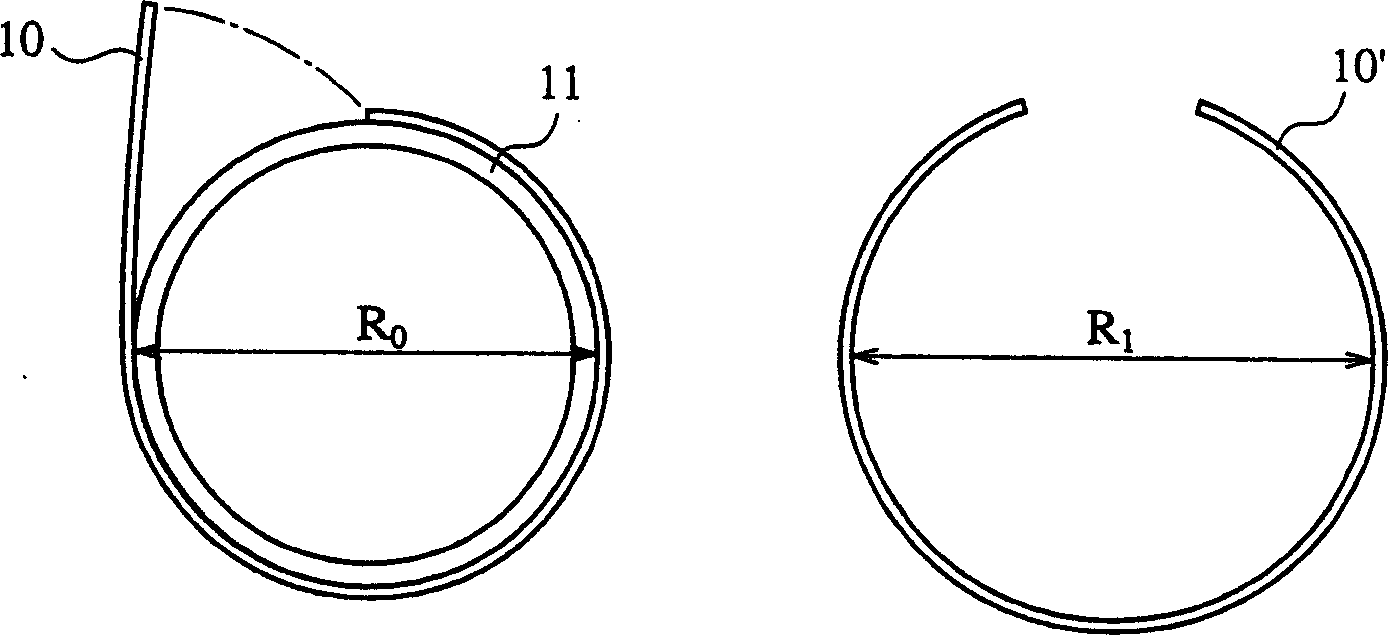

[0035] Such as image 3 As shown ...

Embodiment 2

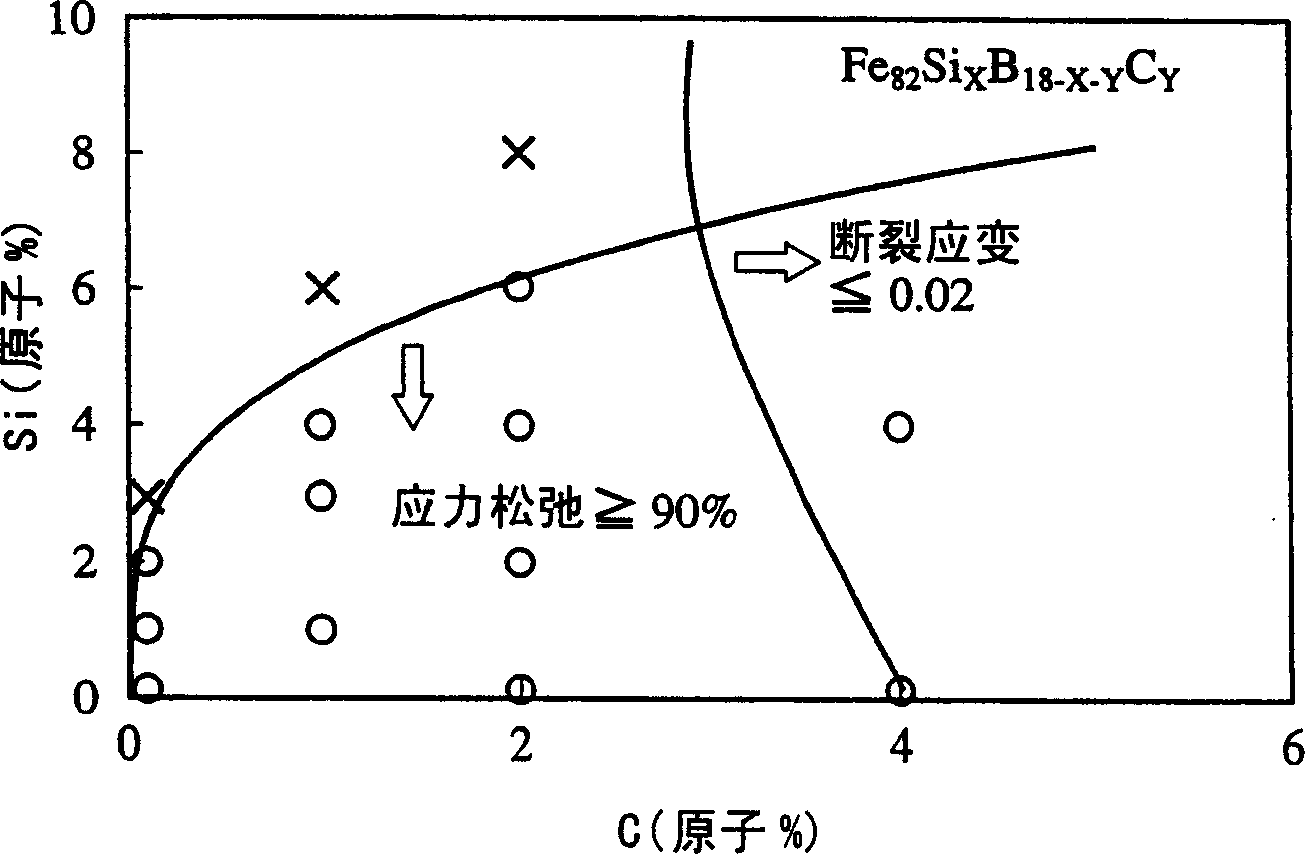

[0047] In the same manner as in Example 1, 200 g of an alloy melt having the composition shown in Table 3 was rapidly quenched to form a Fe-based amorphous alloy ribbon with a width of 5 mm and a thickness of 23 to 25 μm. The properties of each Fe-based amorphous alloy ribbon are listed in Table 3. B 80 High Fe-based amorphous alloy ribbons can maintain low core loss at high operating flux densities. Elemental analysis was performed in the depth direction of sample 8 from the roll contact surface thereof. The result is as Figure 5 shown. The average surface roughness Ra of samples 7 to 22 was 0.38.

[0048] sample

[0049] sample

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| fracture strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com