High differential pressure high accuracy cage type pressure regulating device

A high-precision, high-pressure differential technology, applied in fluid pressure control without auxiliary power, safety valves, engine components, etc., can solve the impact of service life, pressure regulator pressure adjustment range and adjustment accuracy limitations, rubber film strength is difficult Meet the use requirements and other issues, to achieve the effect of prolonging the service life, small fluctuations, and small pressure differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

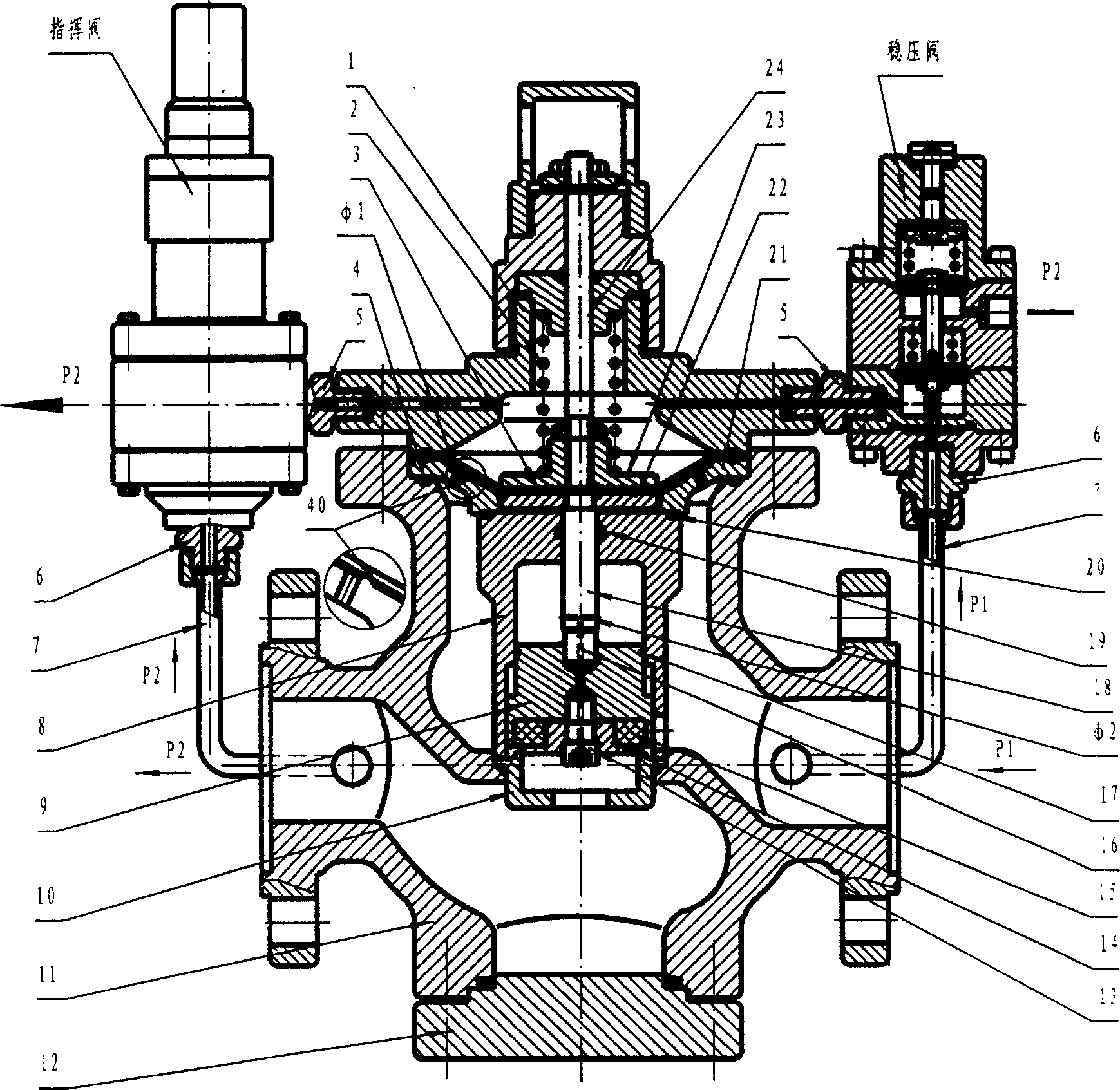

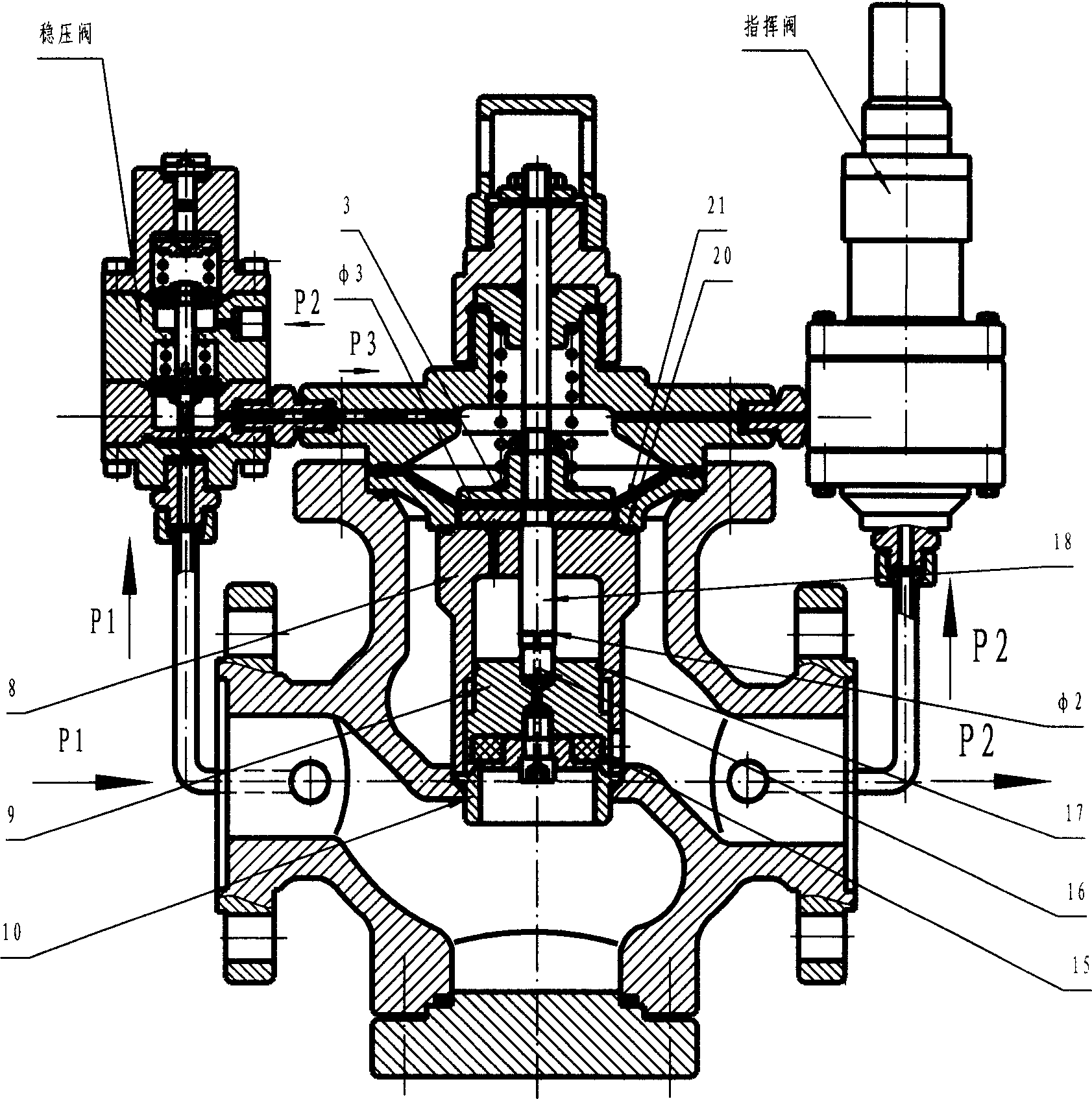

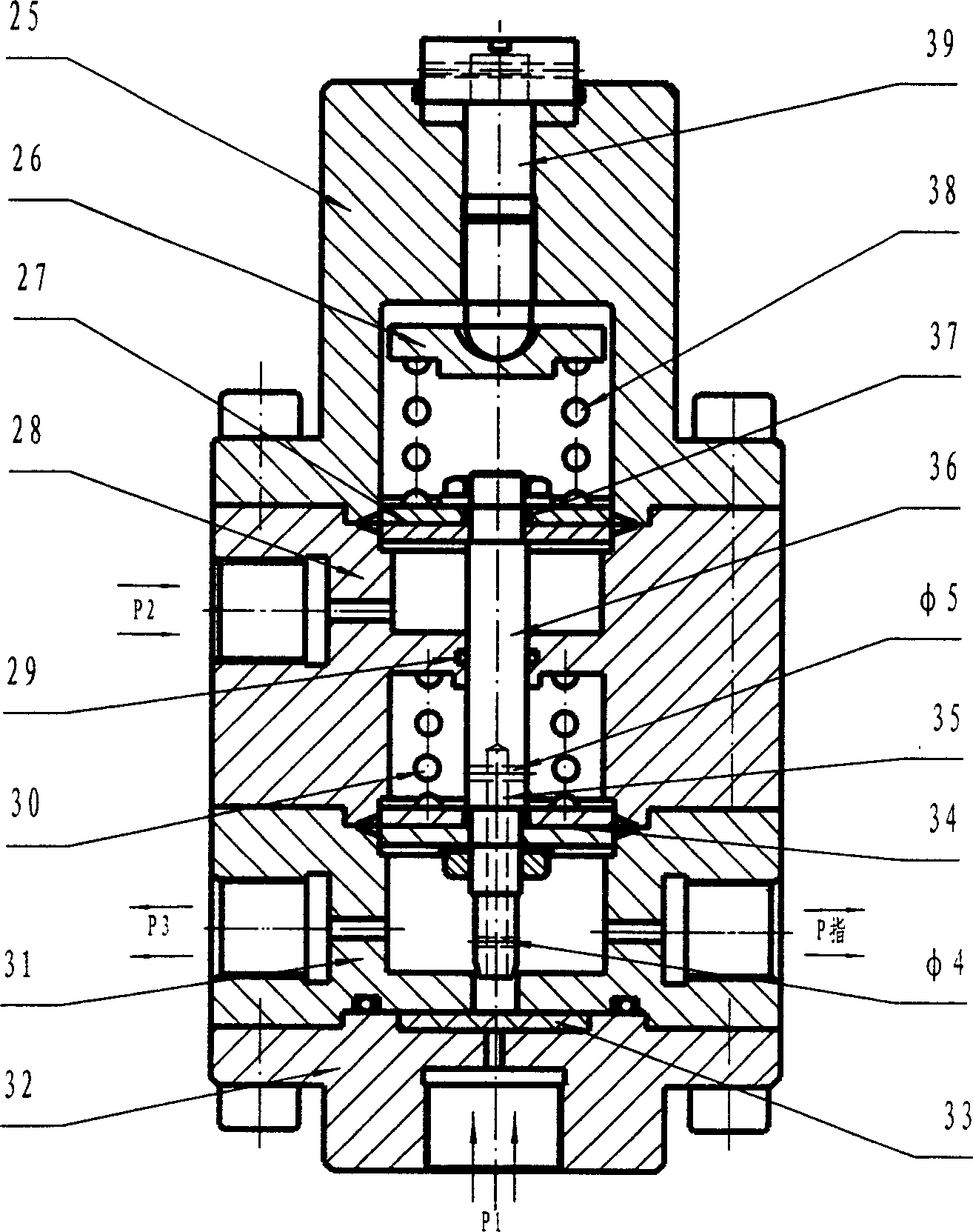

[0022] The present invention will be further described below according to the accompanying drawings:

[0023] figure 1 Shown is one of the embodiments of the present invention. The pressure regulator of the present invention is composed of a main valve, a pressure stabilizing valve and a pilot valve. It is the actuator; the function of the pressure stabilizing valve is to use the medium pressure and the spring force to make the change of the inlet and outlet pressure of the main valve always make the control pressure of the membrane chamber of the main valve change towards the set pressure stability direction, increasing The adjustment range can reduce the adjustment pressure residual value and improve the adjustment accuracy; the function of the command valve is to feed back the signal tube to the command valve diaphragm chamber according to the change of the inlet and outlet pressure of the main valve, and change the change of the valve opening degree to realize the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com