Apparatus for heat recoverin multigrade flash desalting of sea water

A flash evaporation, thermal technology, applied in the field of water, waste water, sewage or sludge treatment, can solve the problems of small water production, aggravated system corrosion and scaling, small water production ratio, etc., to avoid the water production ratio The effect of decreasing, stable water production, and improving the water-making ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

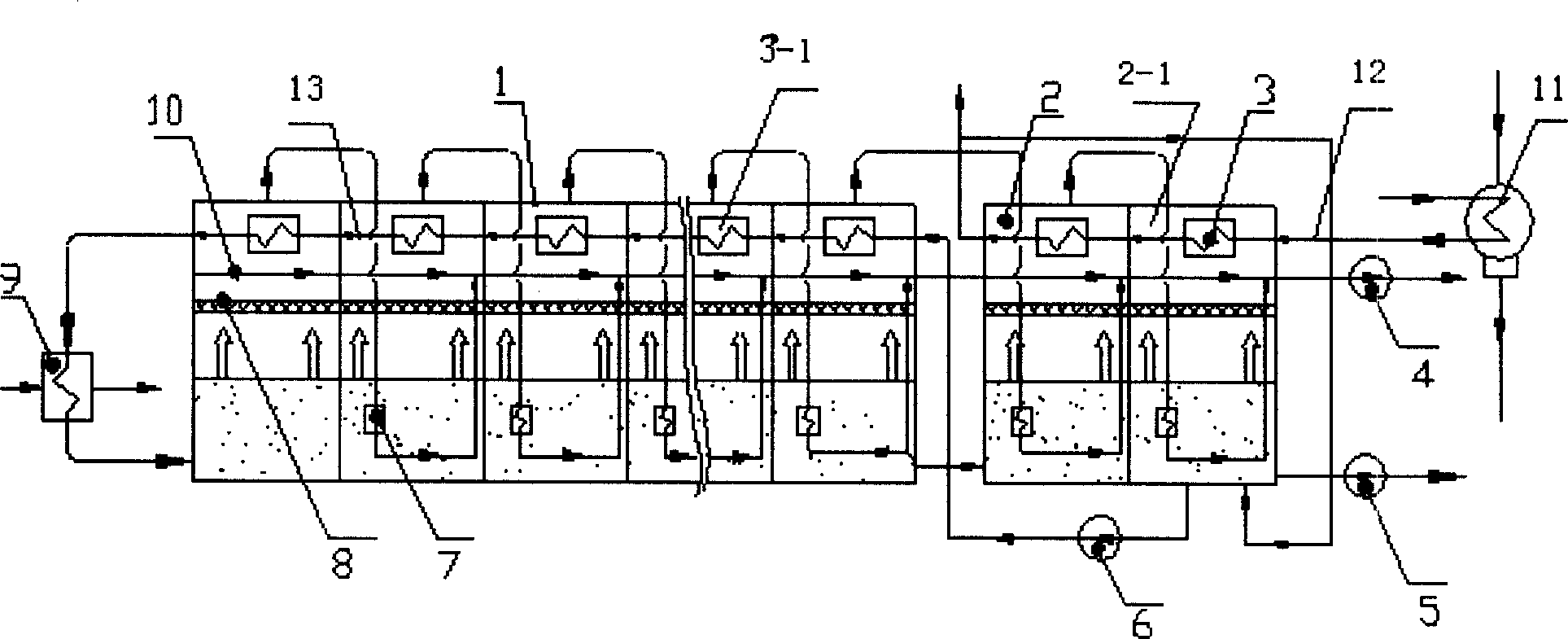

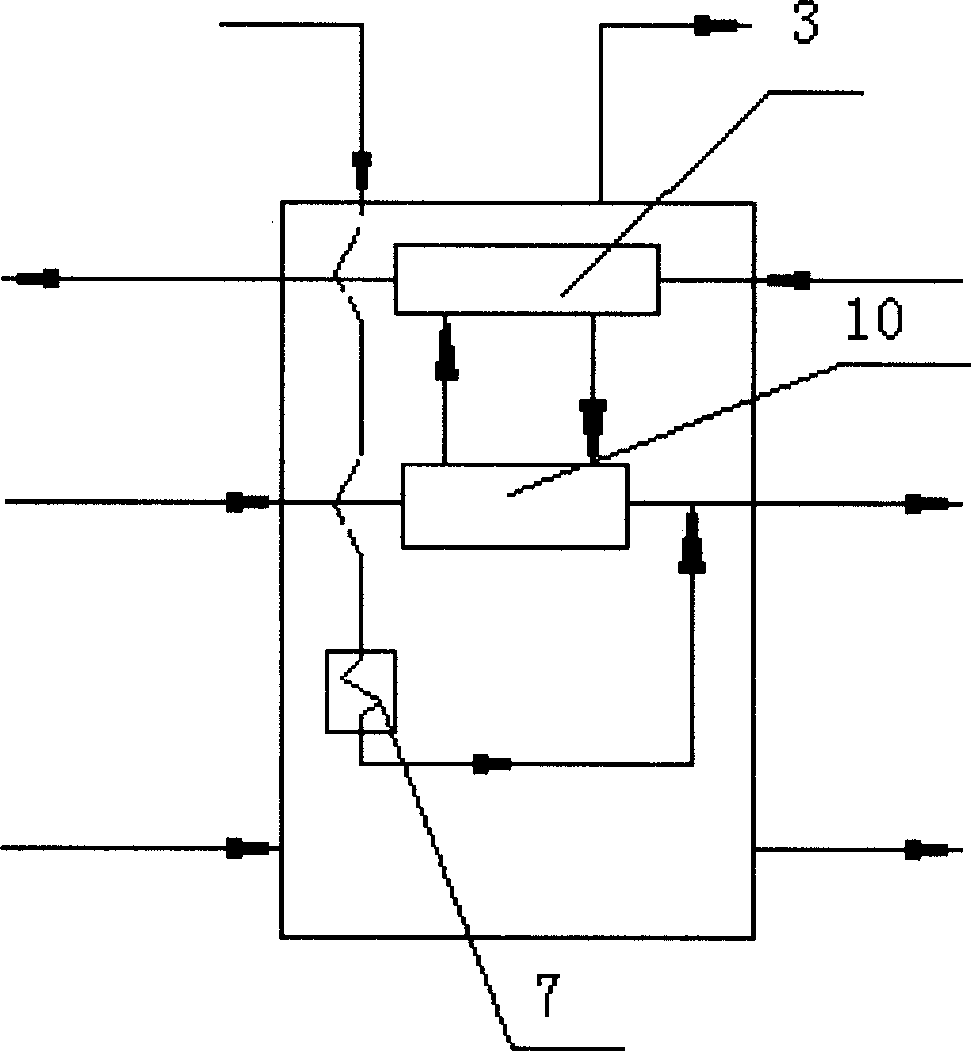

[0009] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0010] See figure 1 , 2. The present invention includes a hot discharge section circulating brine pipe 12 with an inlet connected to a condenser 11, the hot discharge section circulating brine pipe 12 passes through the upper end of the hot discharge section flash chamber 2 and flashes in the hot discharge section The circulating brine pipe 12 in the chamber 2 is also provided with a condenser 3 respectively. The outlet of the circulating brine pipe 12 in the heat discharge section is connected to the bottom end of the flash chamber 2-1 at the last stage of the heat discharge section, and the upper stage heat discharge The steam outlet of the flashing chamber 2 is connected to the lower end of the flashing chamber 2 of the next-stage hot discharge section through pipelines. The flashing brine at the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com