Revolving plate for a sliver depositing device

A technology of fiber slivers and turntables, which is applied in fiber processing, transportation and packaging, textiles and papermaking, etc., and can solve the problems of fiber sliver accidental drafting, deterioration of fiber parallelism, and damage to fiber sliver quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

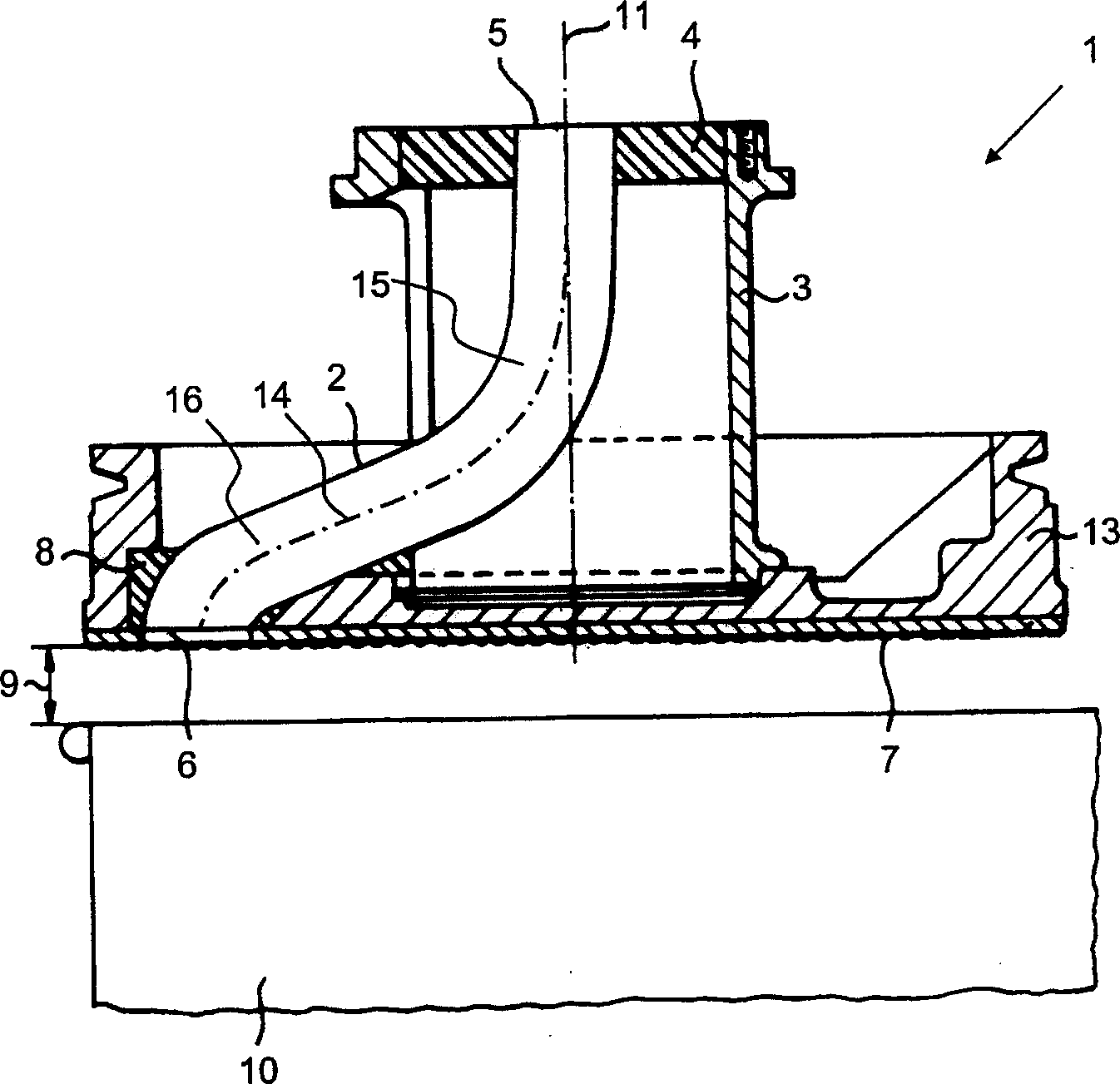

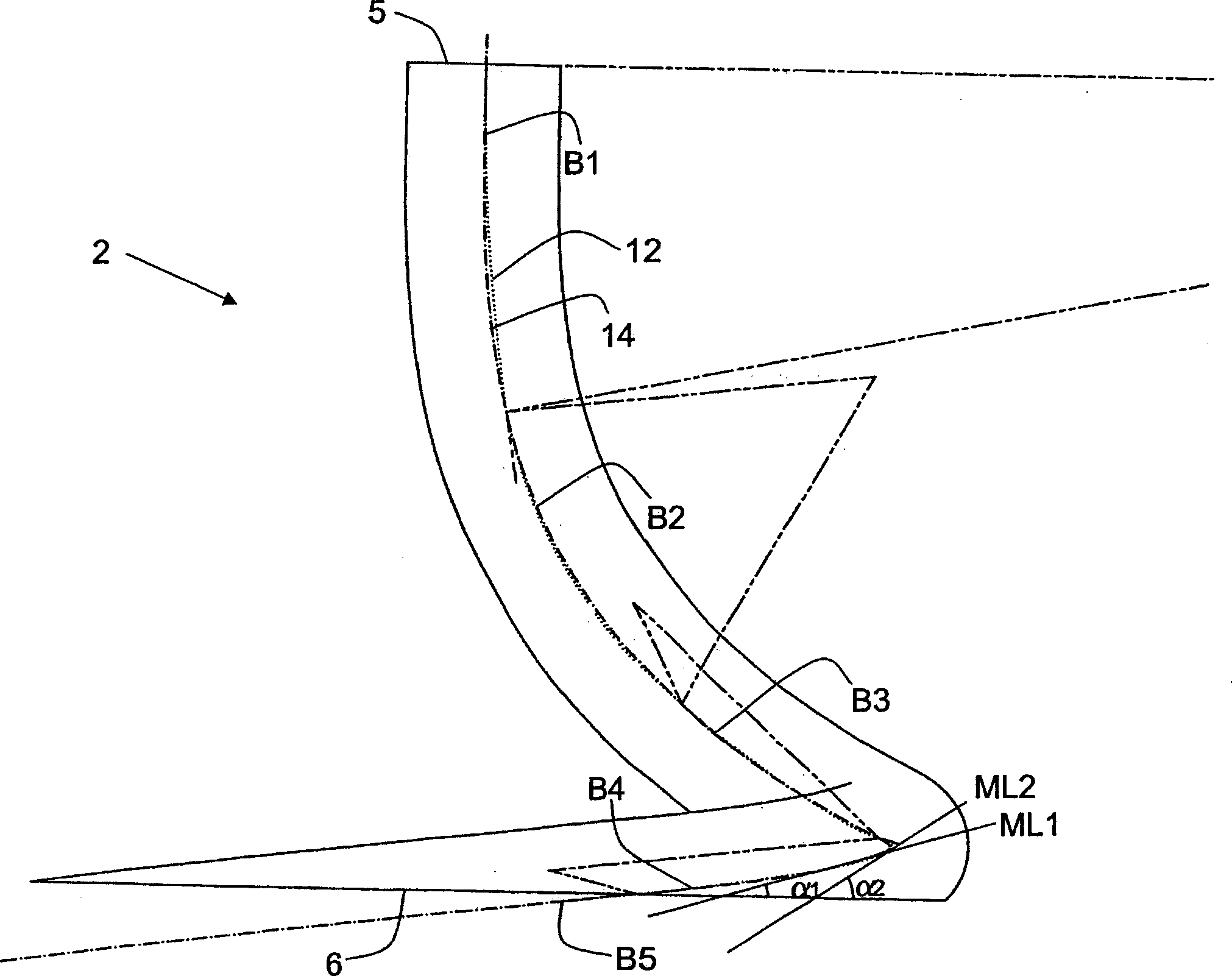

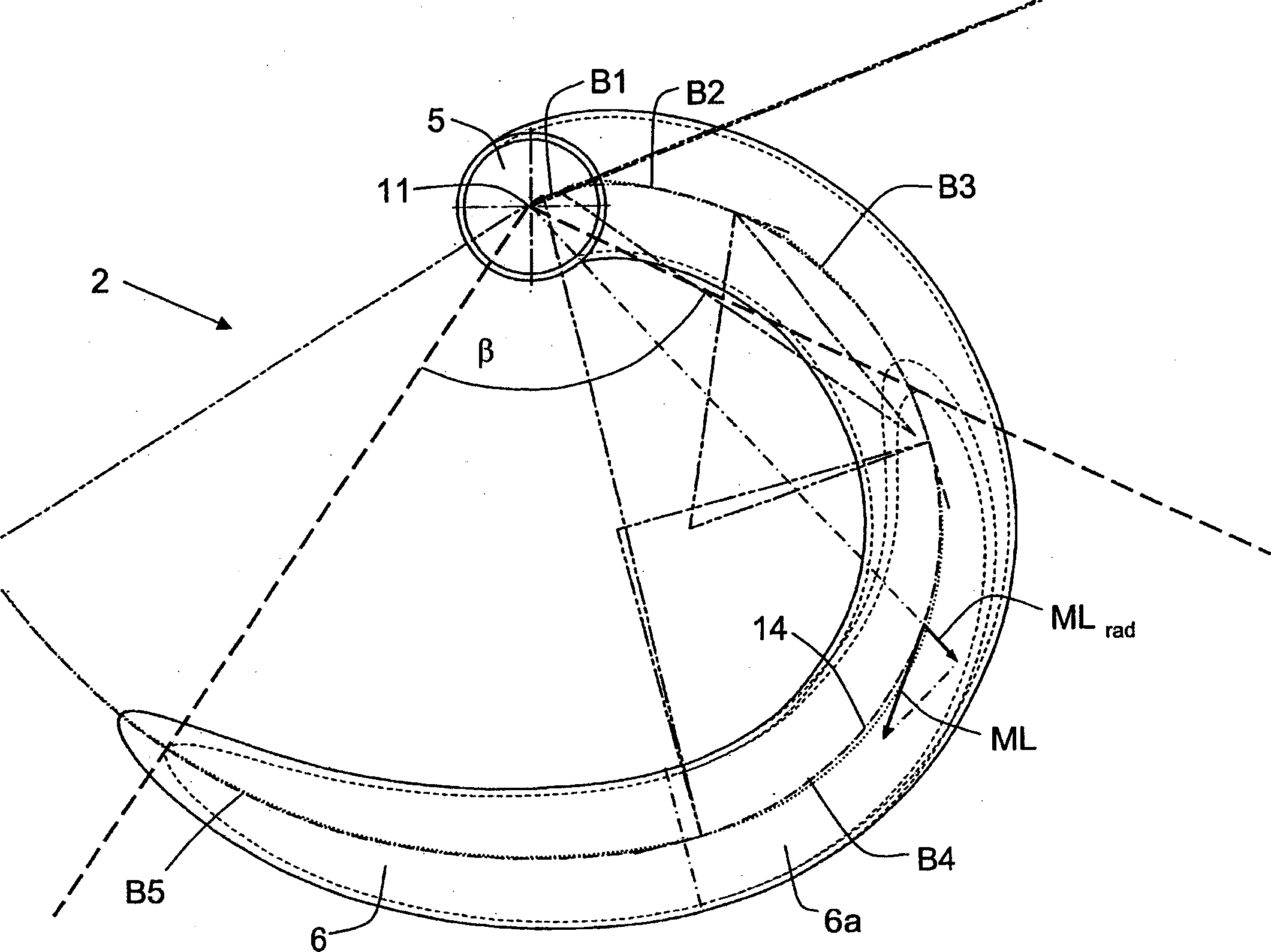

[0045] according to figure 1 , the known turntable 1 includes a disc body 13, a disc frame 3 and a centerline 14 space curve fiber strip pipe 2. The upper end of the fiber strip pipeline 2 utilizes casting material 4 to be fixed on the disc frame 3, and the lower end utilizes 8 casting materials to be fixed on the disc body 13. The disc body 13 has a pressing plate surface 7 at its lower end. During operation, the turntable 1 rotates around its axis 11 . The method of rotating disk support and rotation is not shown among the figure.

[0046] The fiber sliver enters the fiber sliver pipeline 2 parallel to the rotating shaft 11 within the scope of the input port 5, then turns around and leaves the fiber sliver pipeline through the output port 6 and enters the can 10 for stacking. The output port 6 is on the pressure plate surface 7 on the plane. The distance 9 between the pressing plate 7 and the can 10 will be chosen so small that it is impossible for the stacked fiber stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com