Glue board and fabricating method

A kind of plywood and integrated technology, applied in the direction of manufacturing tools, chemical instruments and methods, wood layered products, etc., can solve the problems of short service life, increased waste, easy softening of glue nails, etc., to reduce unnecessary damage, effective and reasonable application, economic benefit prolonging the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

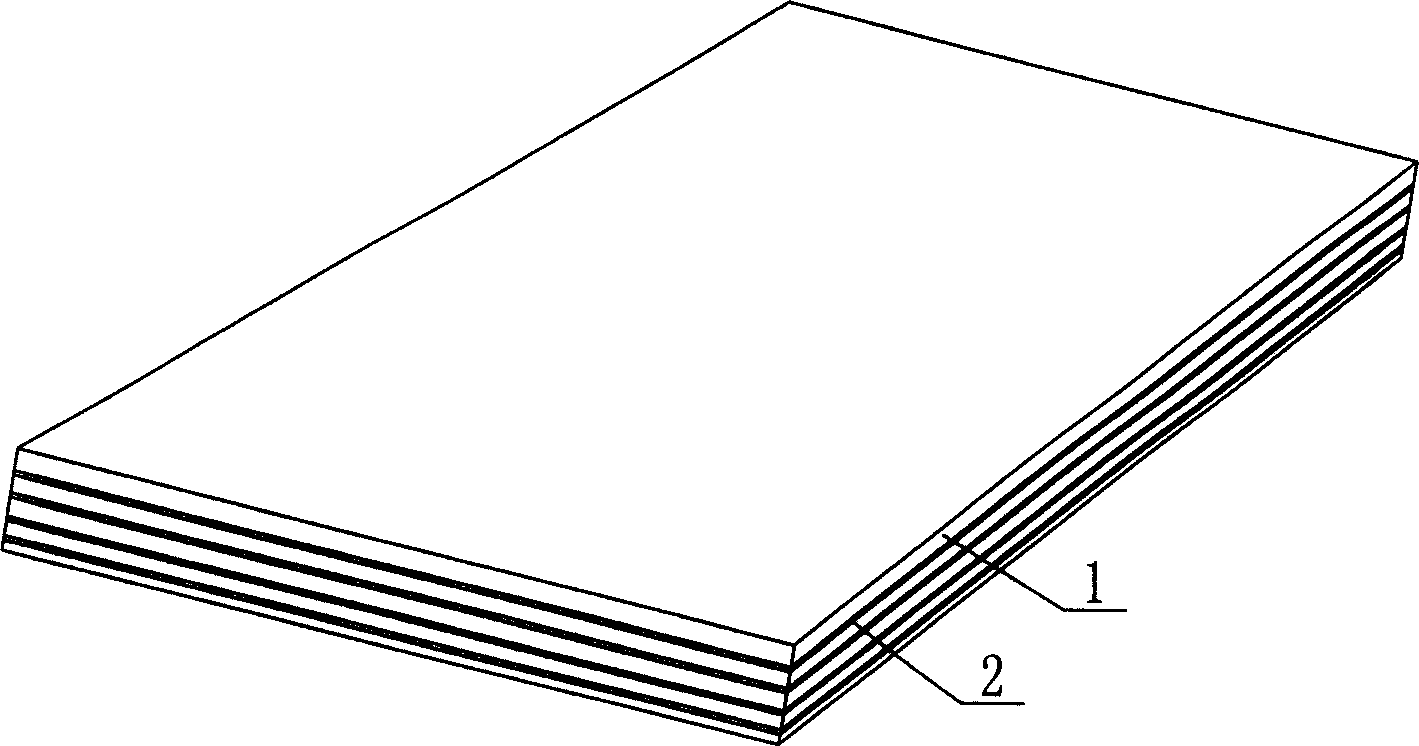

[0033] like figure 2 As shown, the plywood of the present invention is made up of at least two layers of superimposed veneers 1, and is characterized in that a layer is formed between two adjacent veneers 1 by recyclable PE or PP or PET or other waste plastics. The polymer film layer 2, wherein each of the veneers 1 is glued and connected as a whole by the polymer film layer 2 between two adjacent veneers 1 being heated and pressurized in a molding machine and melted into a glue nail.

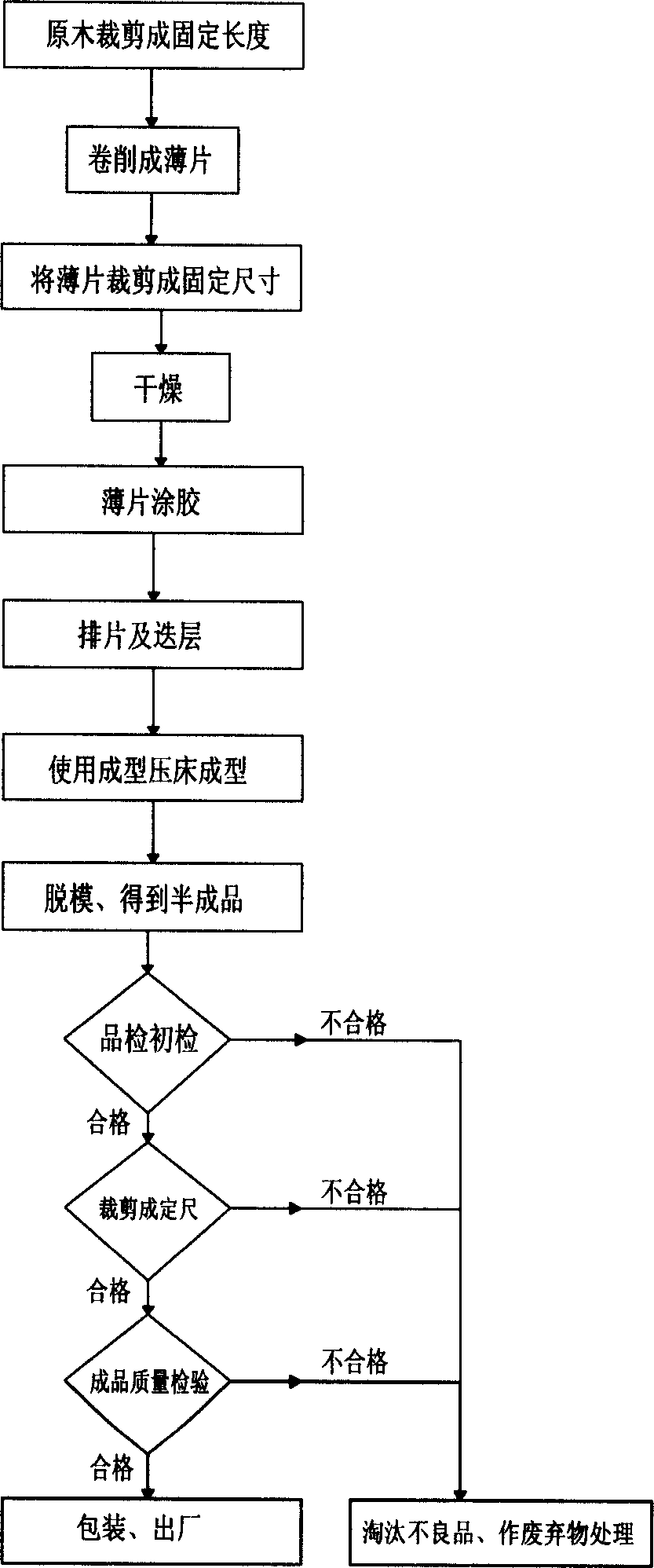

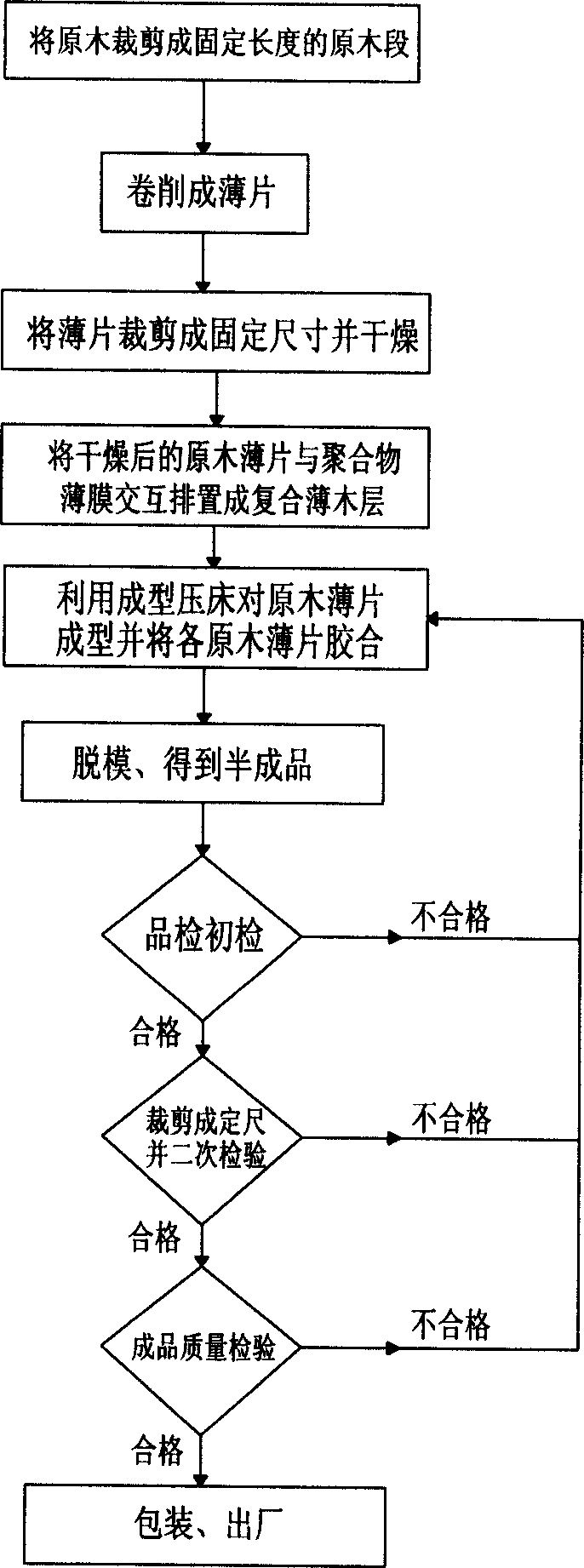

[0034] like image 3 Shown, the manufacture method of plywood of the present invention comprises the following steps:

[0035] (1), cutting the logs into log segments of suitable length;

[0036] (2), cutting the log section cut into a suitable length into log thin slices;

[0037] (3), cutting the log flakes into specifications and drying them;

[0038] (4), alternately arrange and laminate the dried log sheets and polymer films made of recyclable waste plastics such as PE, PP or PET to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com