Ultrasonic wave and laser system for measuring three-dimensional space

A three-dimensional space, laser system technology, applied in the field of ultrasonic and laser systems, can solve problems such as errors, terrain damage, impact tests, etc., to achieve the effect of simple external structure, short time consumption, and easy movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

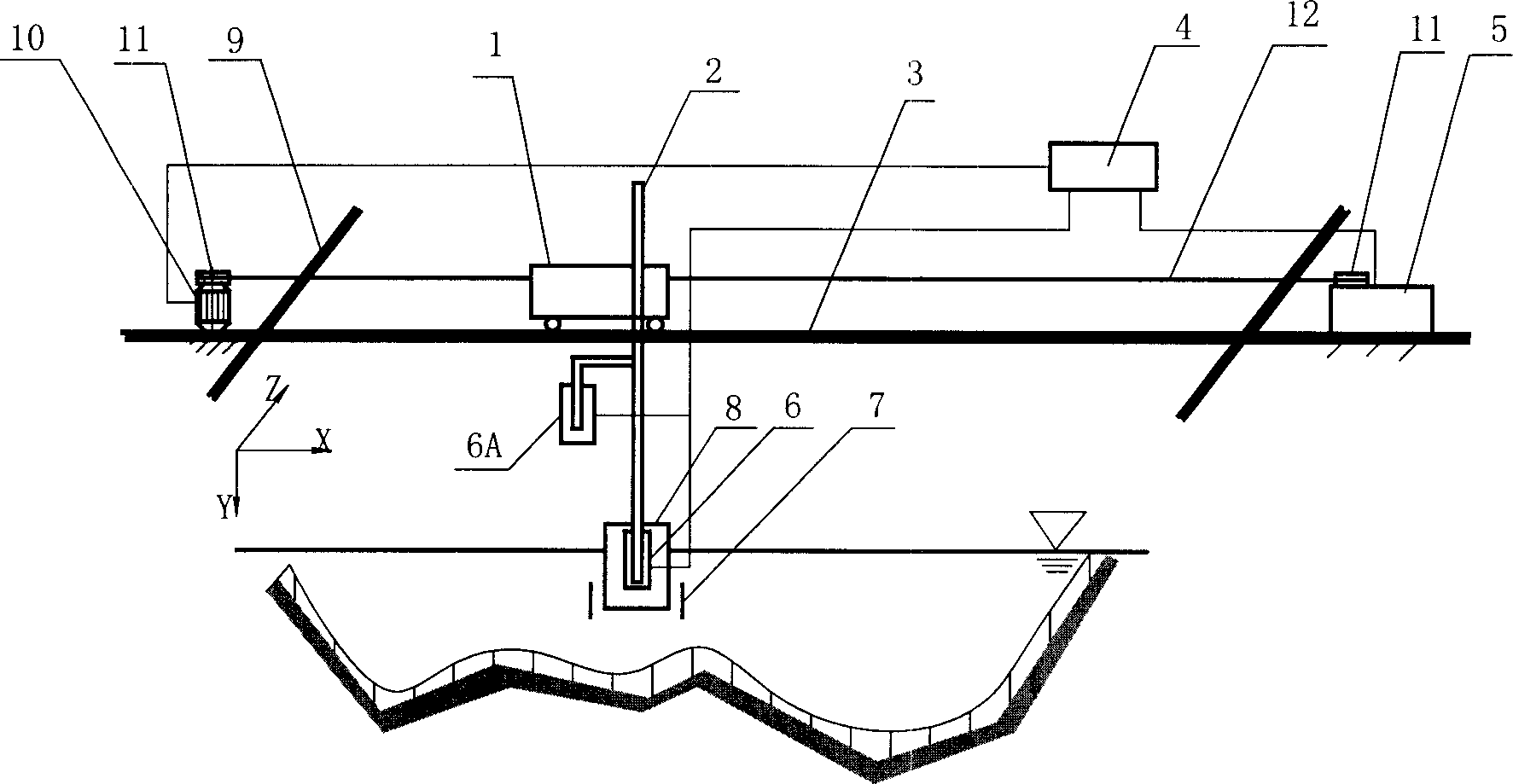

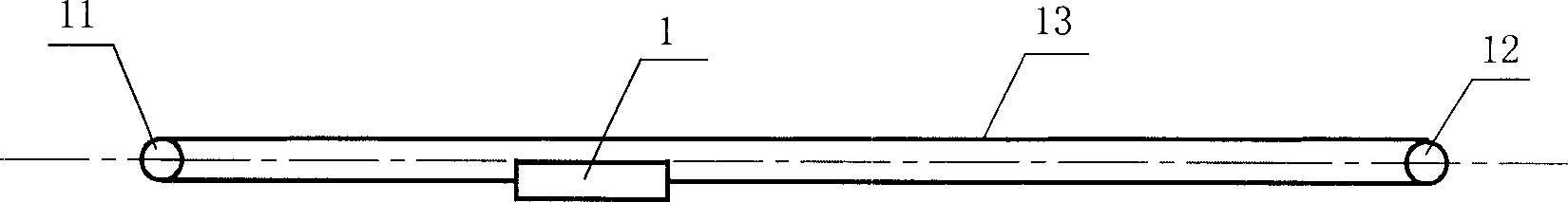

[0014] Such as figure 1 Shown, a kind of ultrasonic and laser system of measuring three-dimensional space of the present invention, it comprises: a computer 4, the horizontal guide rail 3 that straddles the river channel erection on the measured river channel, the fixed laser measuring instrument at one end of the lateral guide rail 3 The distance meter 5, the stepping motor 10 fixed at the other end of the transverse guide rail 3 and the measuring vehicle 1 sliding on the transverse guide rail 3, the stepping motor 10 drives the measuring vehicle 1 to slide laterally on the transverse guide rail 3 through the steel cable 12, stepping Pulley 11 is respectively housed on the motor 10 and the laser rangefinder 5, and steel cable 12 walks around two pulleys 11, and measuring vehicle 1 can be connected with one or two points of the front, rear, left or right of steel cable 12, certainly also can be as figure 2 As shown, the test car 1 is connected to the front and back of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com