Dairy protein process and applications thereof

A technology of whey protein and denatured whey protein, which is applied in application, dairy products, animal protein processing, etc., can solve the problem of high processing cost and achieve high solubility, high yield, and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

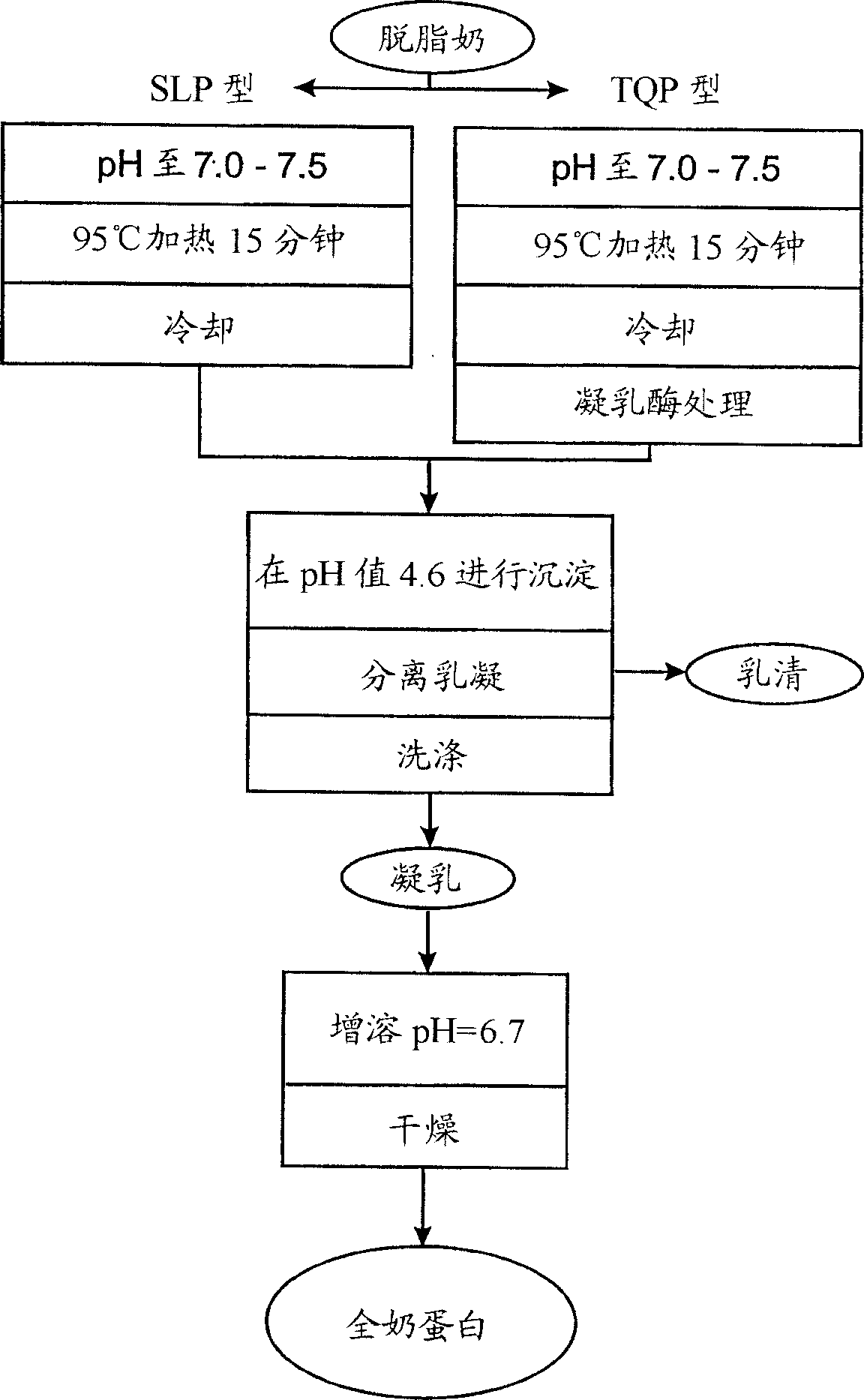

Method used

Image

Examples

Embodiment 1

[0129] Example 1 - Heat Treatment of MPC Solutions: Denaturation of Whey Proteins

[0130] A laboratory-scale test was carried out in which reconstitution was carried out by mixing an appropriate amount of CS-MPC85 powder (produced using the method described in International Application Publication No. WO 01 / 41578) in demineralized water at 35 °C (pH 6.9, 15%, w / w). Each of the four 1 L samples was indirectly heated as follows:

[0131] ●Control - no heating

[0132] ●Heat at 85°C for 7 minutes

[0133] ●Heat at 90℃ for 7 minutes

[0134] ●Heat at 95°C for 7 minutes

[0135] The MPC sample was conveyed through a heated tube, where it was heated by steam, and the flow rate was adjusted to achieve the time-temperature combination. The heated samples were then acidified with 5% sulfuric acid (pH 5.6, 20°C, followed by rennet treatment, 0.1%) to form curds. Whey obtained from each sample was analyzed and the amount of denatured whey was quantified using SDS-PAGE as described...

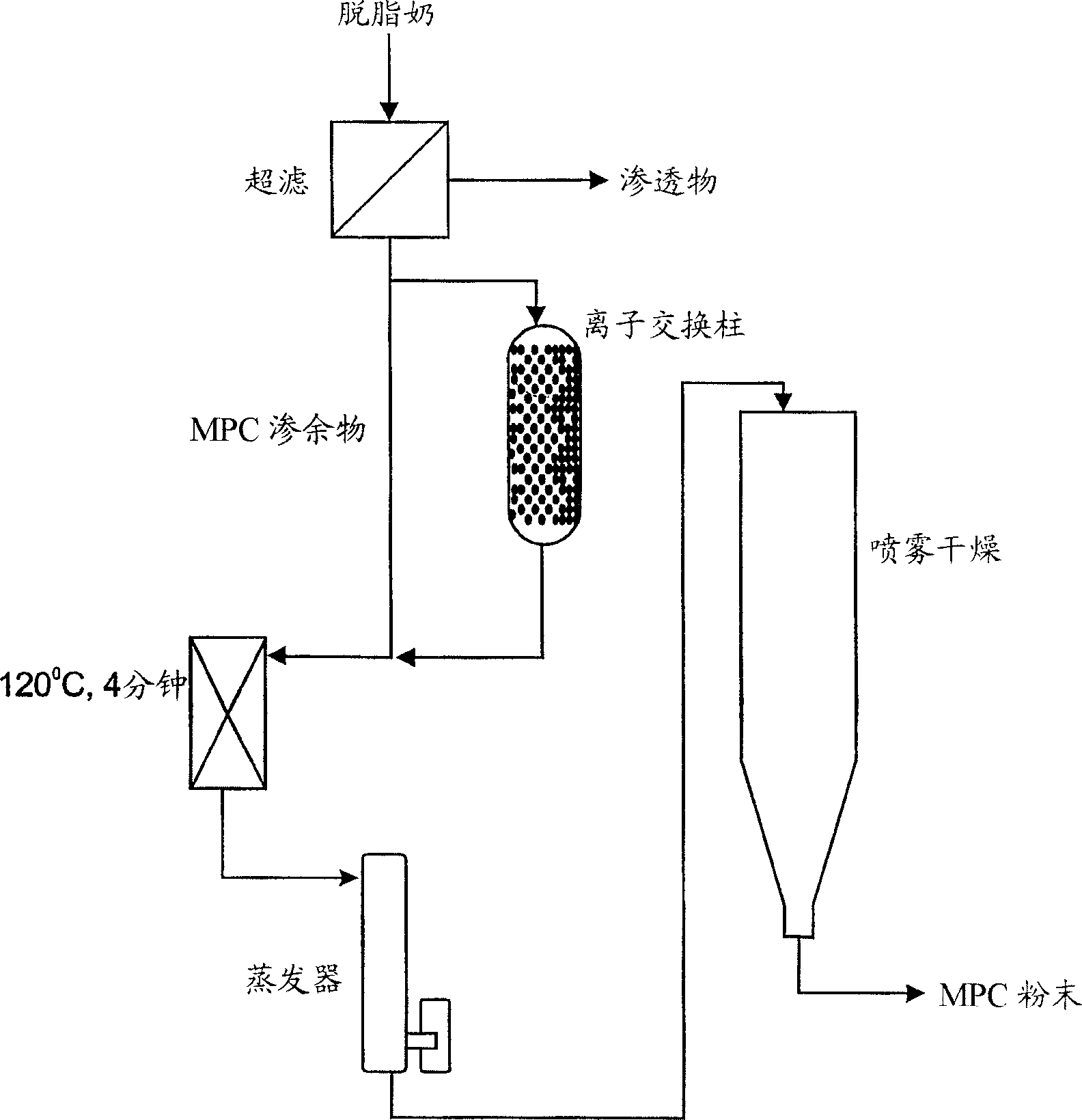

Embodiment 2

[0139] Embodiment 2-The low-temperature solubility comparison of standard MPC85 and CS-MPC85

[0140] High temperature heat treated (HHT-MPC85) was prepared by heat treating the standard MPC85 retentate at 120°C for 4 minutes, evaporating, and then spray drying. The CS-MPC85 retentate (International Application WO 01 / 41578) was also heat-treated at 120°C for 4 minutes, then evaporated and dried to obtain HY-MPC85. The solubility of the products was determined and summarized in the table below. The solubility of the powders was determined as described in the disclosure above. When the temperature was 60°C, the method was modified to maintain the water bath at 60°C.

[0141]

Embodiment 3

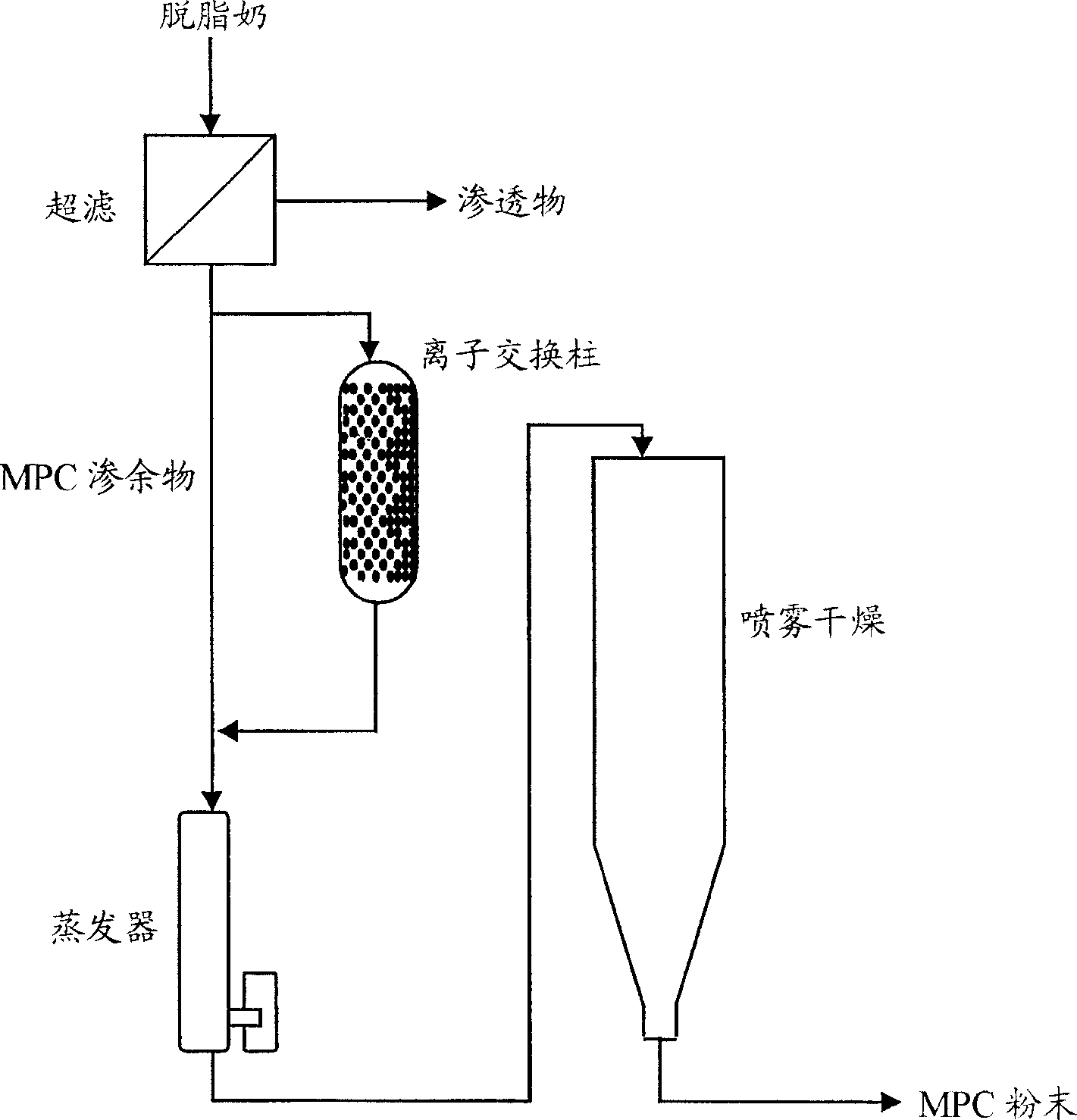

[0142] Example 3 - Ultrafiltration of MPC85 retentate or H from low-pH + - Ion-treated MPC5 retentate to produce HY-MPC

[0143] A skim milk ultrafiltration retentate with a protein content of 85% of SNF was obtained from NZMP (formerly Anchor Products) Hautapu. The retentate was then split into two streams. One stream was diluted with deionized water (~9°C) to bring the total solids to 2%. With 1M of H 2 SO 4 Adjust the pH to pH 3.5. The pH adjusted permeate is split into two streams A and B. Stream A is further decalcified by ultrafiltration. It was diluted (-8% TS) then adjusted to pH 6.9 with 10% caustic and mixed with the untreated feed stream. The MPC is labeled UF-HY-MPC.

[0144] Pass stream B through H + resin to remove calcium. Stream B was adjusted to pH 6.9 with 10% caustic and mixed with the untreated feed stream. The MPC is marked H + -HY-MPC.

[0145] Analysis indicated that the calcium content of the final mixture of the two streams was approximate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com