Method for preparing carrier catalytic element for gas detection in coal mine

A catalytic element, coal mine gas technology, applied in the direction of material resistance, etc., can solve problems such as unsatisfactory production safety, catalytic element poisoning, casualties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

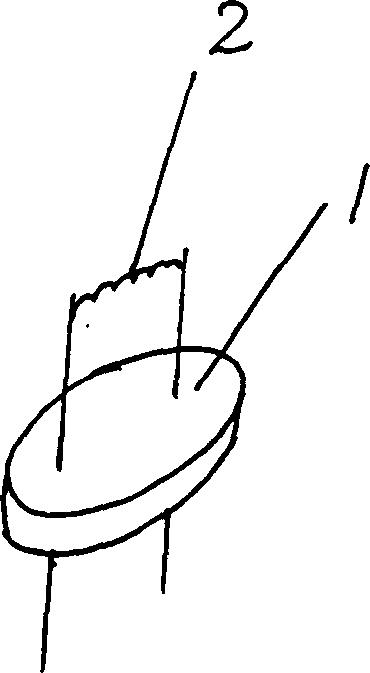

[0005] In the figure, 1 is a stent, and 2 is a platinum wire. Take thin platinum wire 2 (0.02MM in diameter) and wind it on a thin steel core (0.2MM in diameter) for 20 laps, cut it off and soak it in concentrated hydrochloric acid to corrode and remove the thin steel core to obtain platinum wire coil 2, and clean the platinum wire The two ends of the coil 2 are straightened and folded into right angles and welded on the component support 1. After welding, the platinum wire coil is coated with a carrier, which is pasty aluminum nitrate with a concentration of 60%, and then the platinum wire coil 2 is passed through Direct current heating for 20 seconds, the current is 50MA, and the voltage is 2.8V. After the carrier moisture evaporates, the current is increased to 100MA, and heating for 1 minute, so that the aluminum nitrate is completely decomposed. The black element that produces sensitivity is to coat the catalyst on the white element. The catalyst is a mixture of palladium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com