Dynamic scheduling method based on pheromone for semiconductor production line

A dynamic scheduling and production line technology, applied in data processing applications, comprehensive factory control, instruments, etc., can solve problems such as poor flexibility and changing queuing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

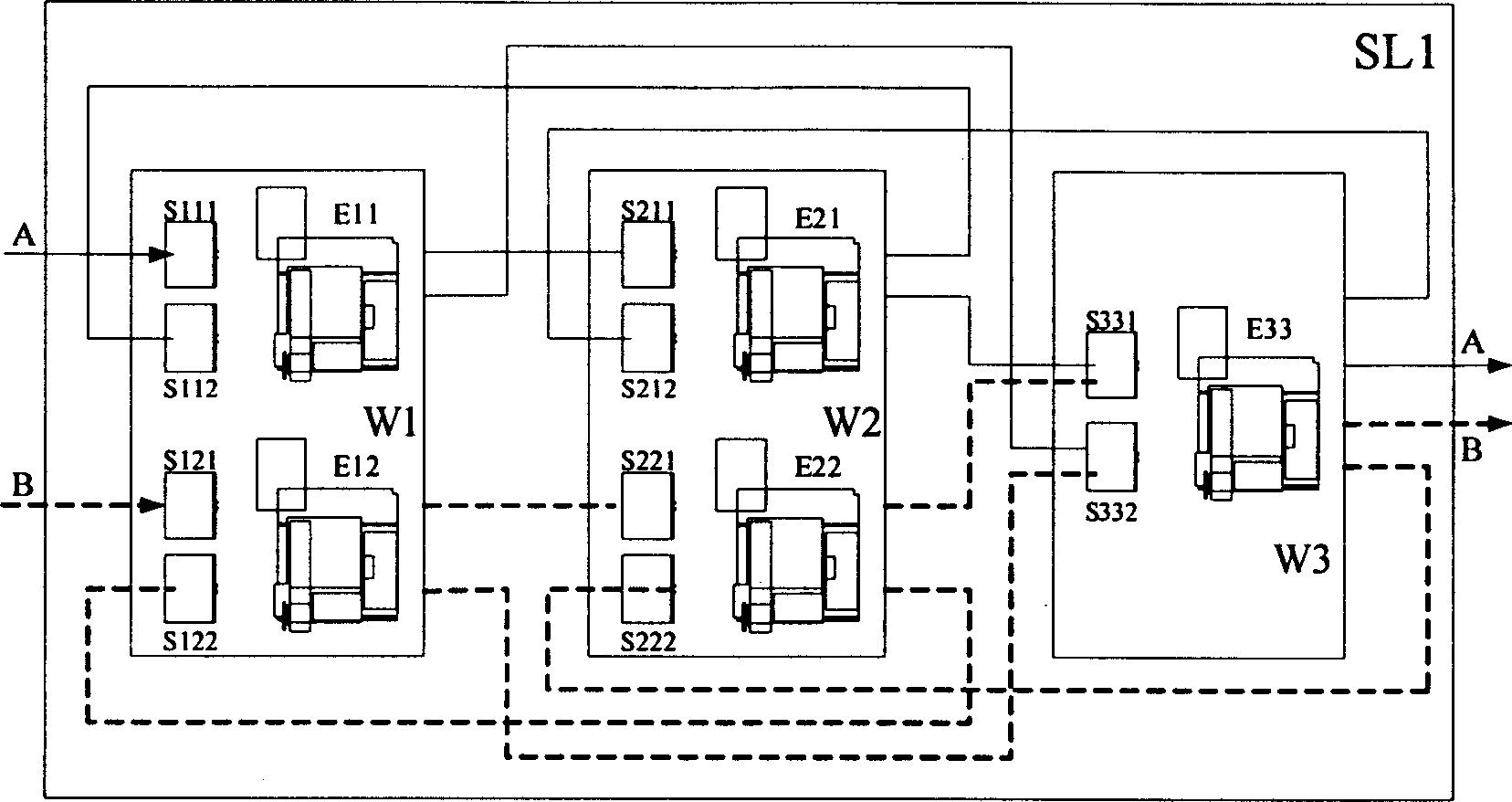

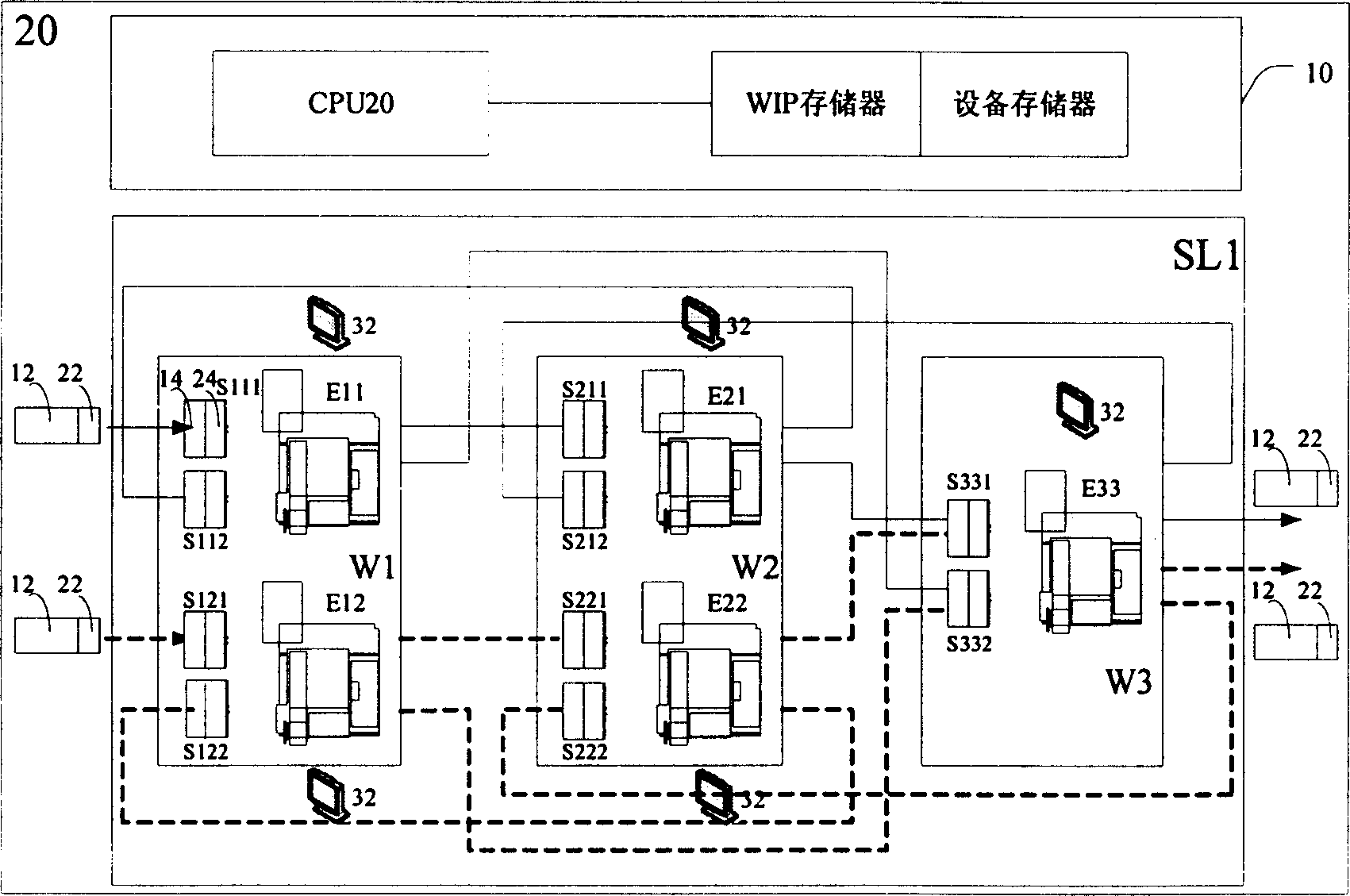

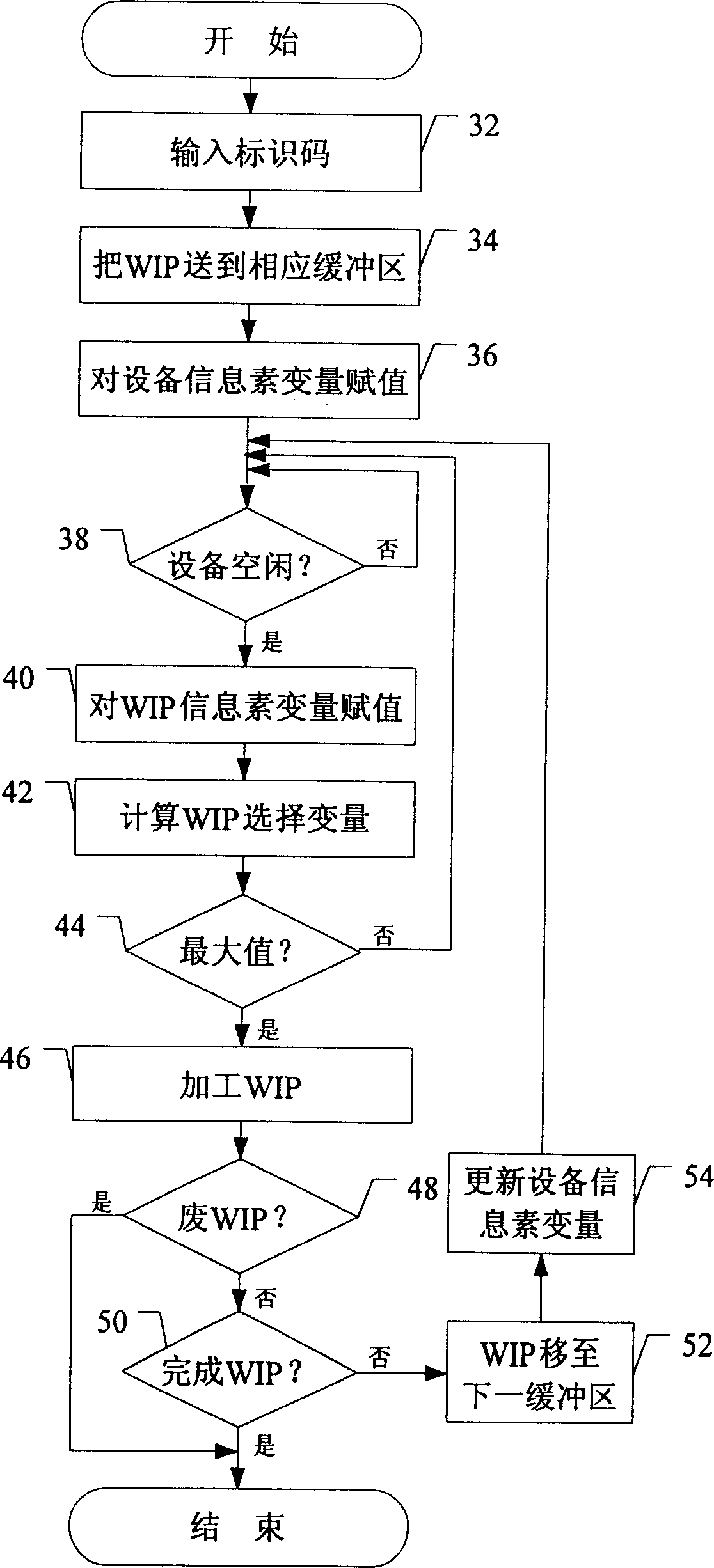

[0061] Further illustrate the concrete technical scheme of the present invention below in conjunction with accompanying drawing description:

[0062] Each WIP in the present invention represents one product among multiple product types manufactured using a semiconductor production line, and the present invention can also be applied to all WIPs in a single product type. The method utilizes a pheromone-based multi-objective optimization method to generate selection variables for WIP awaiting processing at each facility. The method selects the WIP with the largest selection variable for processing at each facility.

[0063] Specifically, once a notification that a certain device is available is received, the method is used to read the selection variables of each WIP in the buffer of the device, and select the WIP with the largest selection variable for processing.

[0064] In addition, when a product is complete, that is, when a WIP is fully processed through a semiconductor pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com