Indirect heating system with upgrading of ultra-fine fuel particles

A heating system and particle technology, which is applied in the direction of the burner for burning powder fuel, fuel supply, solid fuel pretreatment, etc., can solve the problems such as the difficulty of selecting the injection area and the inability to use particles, and achieve the effect of saving fuel costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

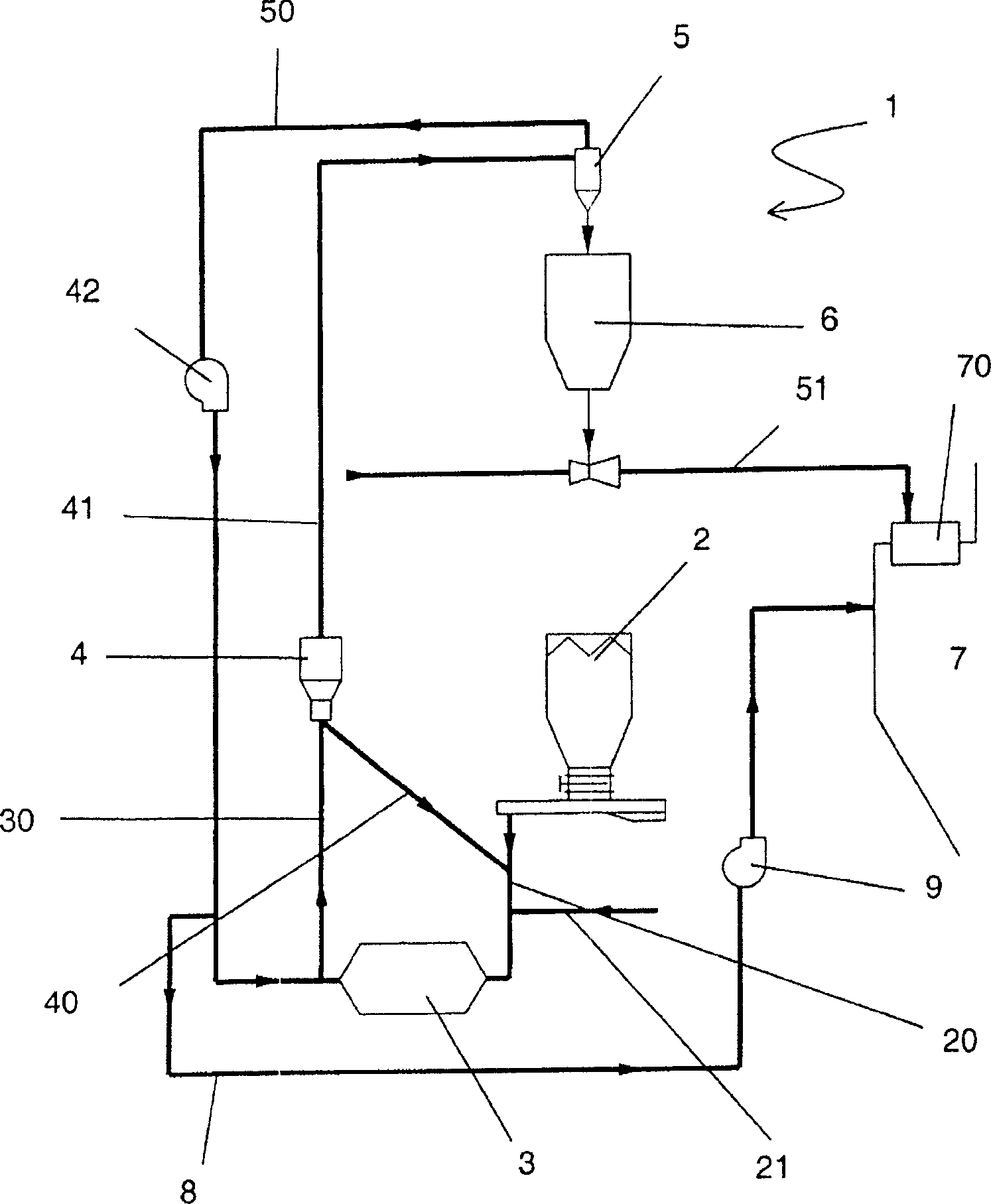

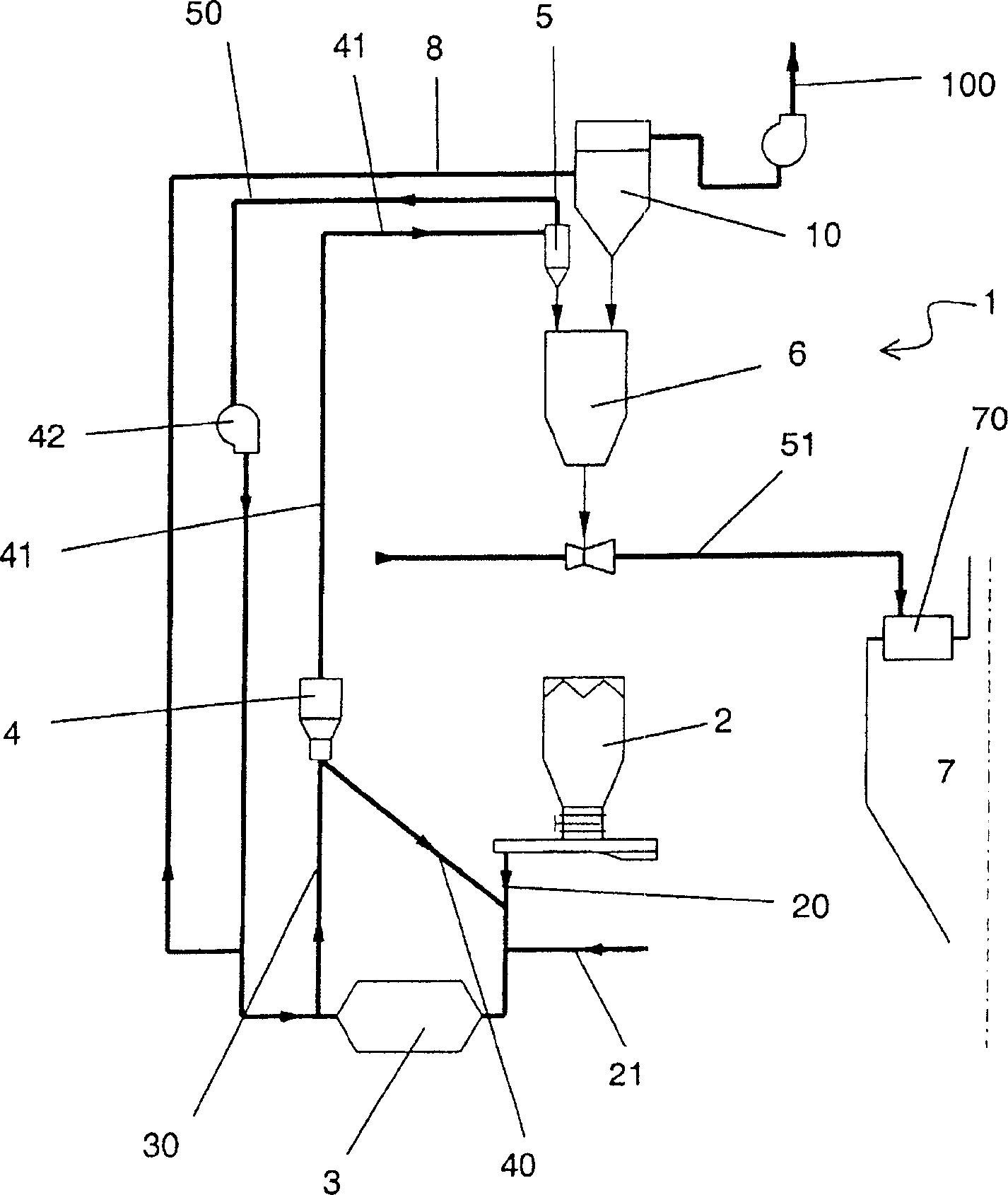

[0032] Existing indirect heating systems1( figure 1 and 2) includes the silos 2 where the raw fuel is stored, and the raw fuel reaches the grinder 3 through a pipe 20 where it is ground and dried by extremely hot air or gas coming through a pipe 21 . The pulverized fuel obtained is conveyed through the pipe 30 under the action of compressed air to the separator 4 which intercepts only the coarse particles and returns them through the pipe 40 to the inlet of the grinder 3 . Other particles are sent through pipe 41 to one or more cyclones 5 functioning to intercept pulverized fuel, after which these particles are released into an intermediate storage silo 6 and then sent through pipe 51 to the main combustion chamber 7. The burner 70 is to be fired. The gases leaving the cyclone 5 are returned to the circuit through the duct 50 and the fan 42 .

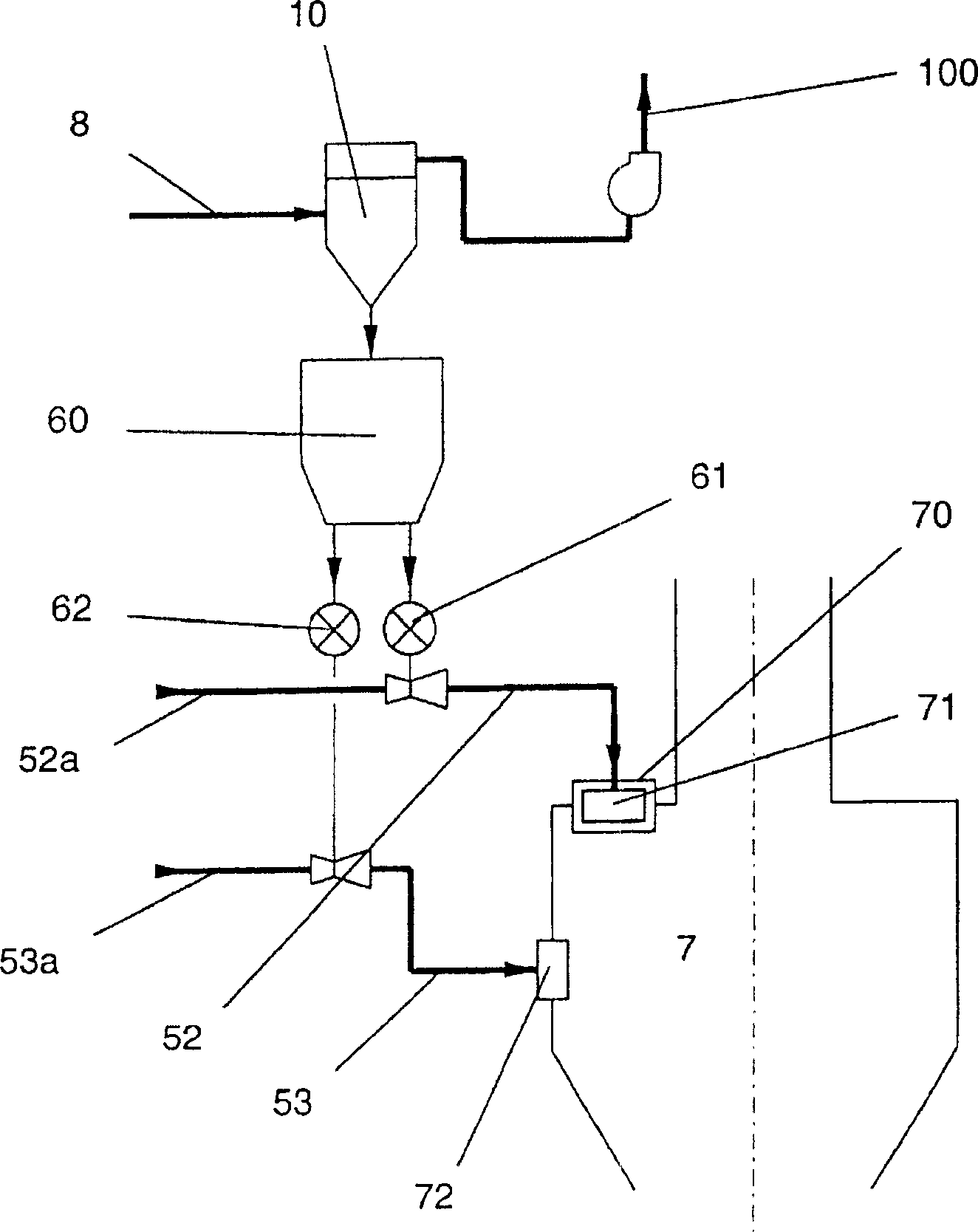

[0033] The milling system receives hot air or gas through duct 21 and itself generates residual gas (for example water vapor from e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com