Honeycomb paperboard pressing and stoving process and apparatus

A technology of honeycomb cardboard and drying device, which is applied to cardboard items, mechanical processing/deformation, etc. It can solve problems such as weak adhesion and unsatisfactory flatness, achieve good heat dissipation effect, reduce cleaning and maintenance work, and improve transmission efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A pressure drying process for honeycomb paperboard, comprising the following steps:

[0019] ①. Paste the upper paper and the lower paper on the upper surface and the lower surface of the pre-coated honeycomb paper core to form a honeycomb paperboard, and press the upper paper and the lower paper respectively when pasting;

[0020] ②. Heat and dry the honeycomb cardboard, and continue to press the upper paper and the lower paper respectively while drying.

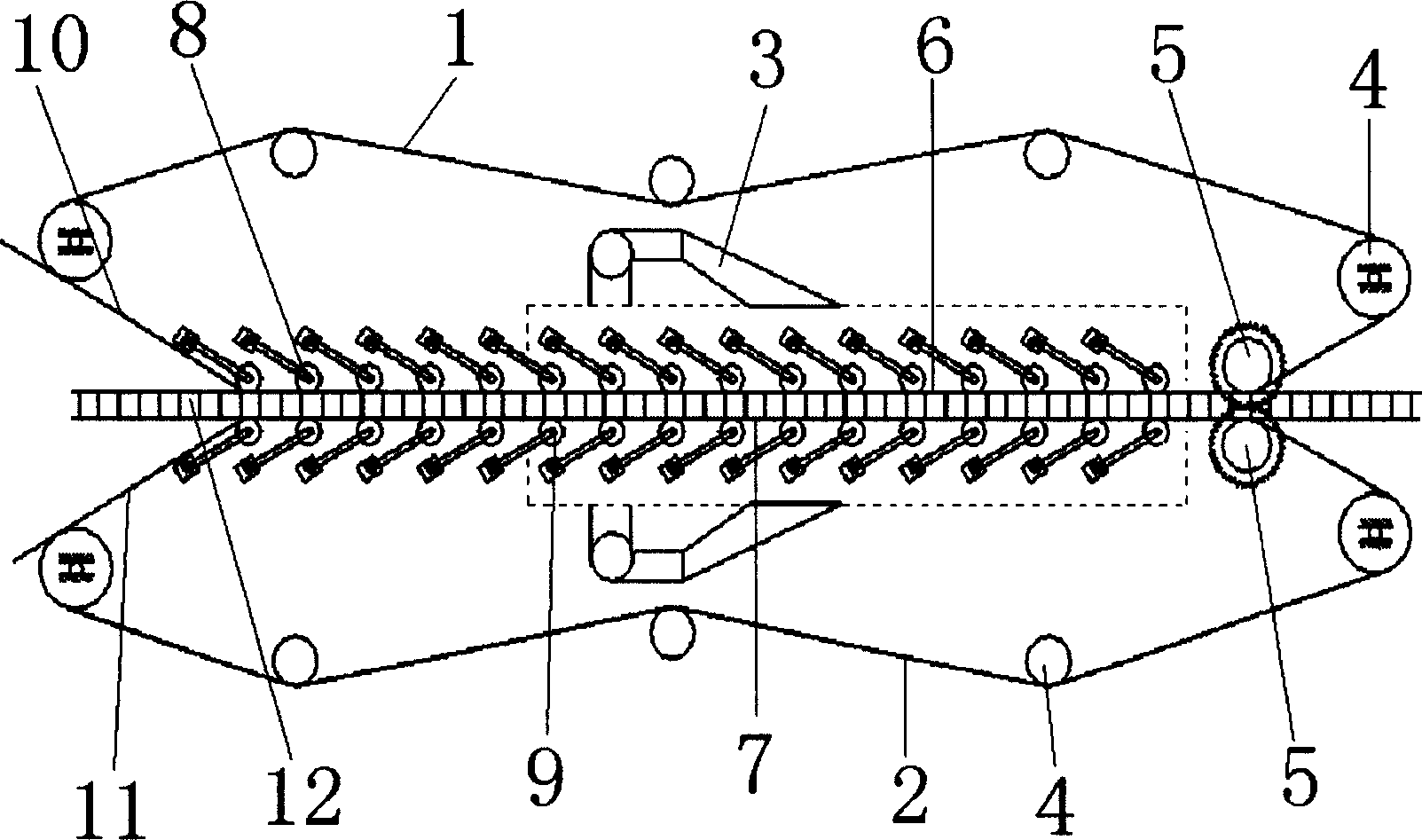

[0021] refer to figure 1 The honeycomb paperboard pressure drying device for realizing the above-mentioned honeycomb paperboard pressure drying process is as follows: comprising a first endless pressure belt 1, a second endless pressure belt 2 and an oven 3, the first endless pressure belt 1, The second endless pressure belt 2 is all tensioned on the respective tension roller 4 and the drive roller 5 that drives it to rotate. The first endless pressure belt 1 is located above the second endless pressure belt 2 .

...

Embodiment 2

[0029] refer to figure 1 , The first endless pressure belt 1 and the second endless pressure belt 2 are both polyester fluorine belts, and are uniformly opened with small holes. The rest of the structure and implementation are the same as in Embodiment 1.

[0030] The specially treated polyester fluorine press belt, and the small holes are reasonably set on the press belt, the heat penetration and heat dissipation effect is good, and the excess glue of the paper core will not stick to it. Even if it sticks, it will fall off by itself in a short time, which greatly reduces The cleaning and maintenance work of the stencil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com