Device and method for defibrating bast fibre plants

A bast fiber, plant technology, applied in the field of bast fiber plant defibrillation, to achieve the effect of improving impact and synchronous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

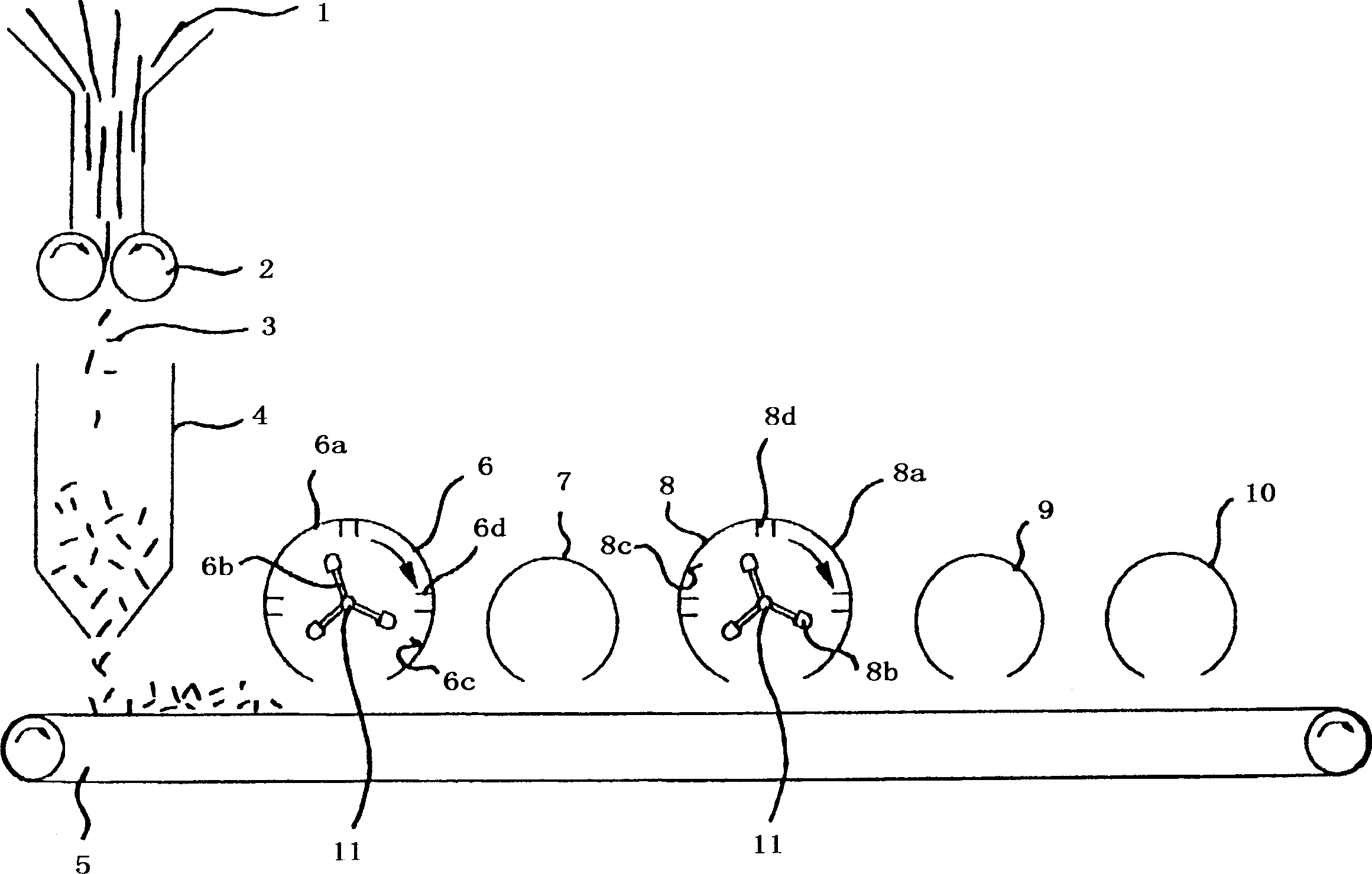

[0025]The raw material 1 is conveyed to the crushing device 2 according to the drawing. The raw material 1 is, for example, stem material of bast-fiber plants like flax, hemp, kenaf, safflower or jute. The raw material 1 is broken up on stem segments, ie pre-cut to the same or approximately the same length. The thus pre-cut raw material 3 then enters the intermediate silo 4 . The raw material 1 is preferably pre-cut to a length of approximately 80 mm to approximately 120 mm, further preferably approximately 120 mm to approximately 160 mm and particularly preferably approximately 160 mm to approximately 200 mm, and then conveyed to the intermediate silo 4 .

[0026] From the intermediate silo 4 the pre-chopped raw material 3 can be dosed onto a conveying device 5 for conveying the pre-chopped raw material 3 to a secondary processing section for disintegration and separation of the fiber fraction from the chips. The pre-cut raw material 3 is conveyed to the first power decompo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com