Fast spraying freezing coldproof method

A fast, metal mesh technology, used in water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve the problem of difficulty in ensuring the cooling effect of cooling towers, artificial ice restrictions, and failure to reach natural cooling water. and other problems, to achieve the effect of being beneficial to economic operation, saving manpower and material resources, and reducing power generation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

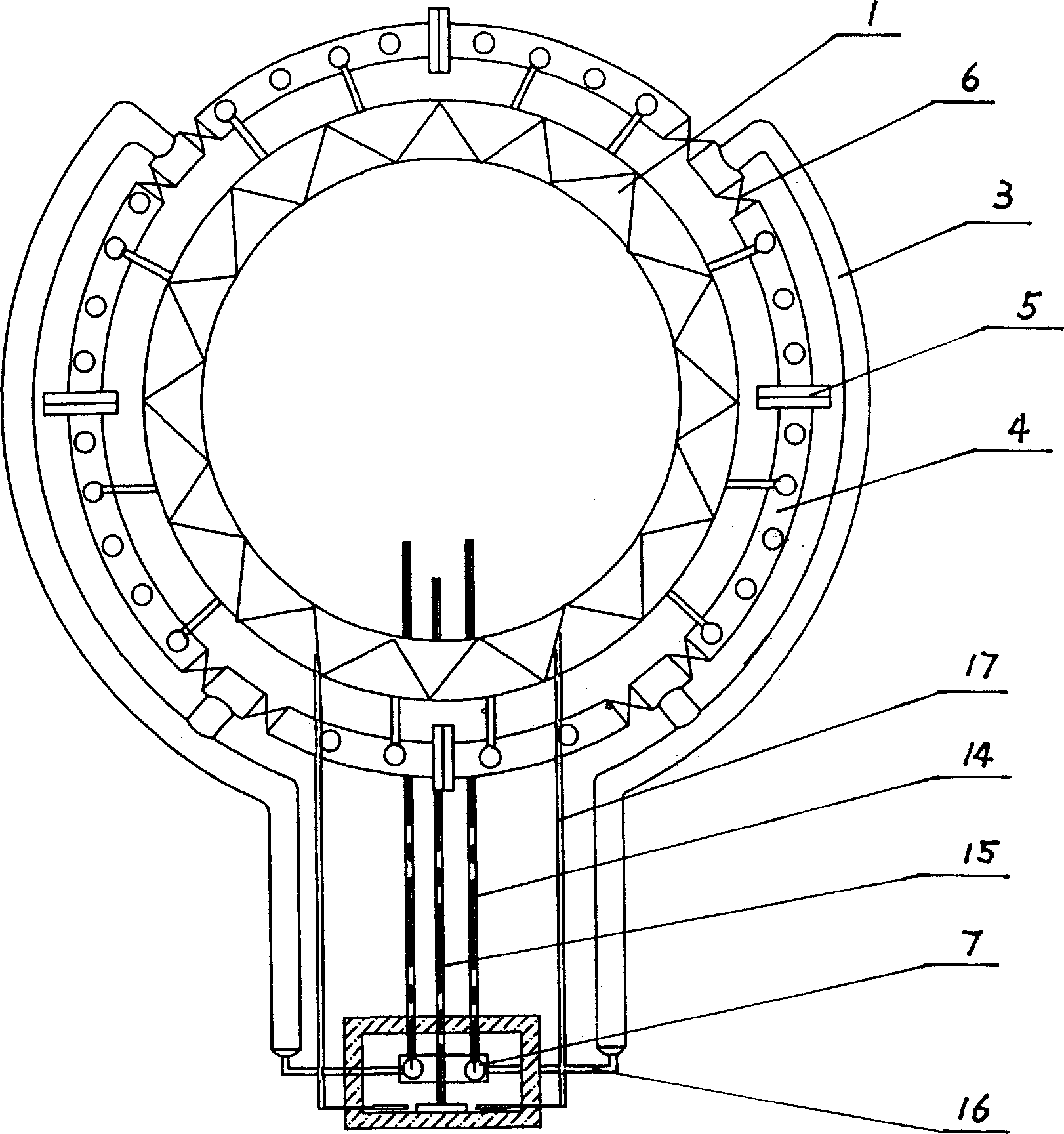

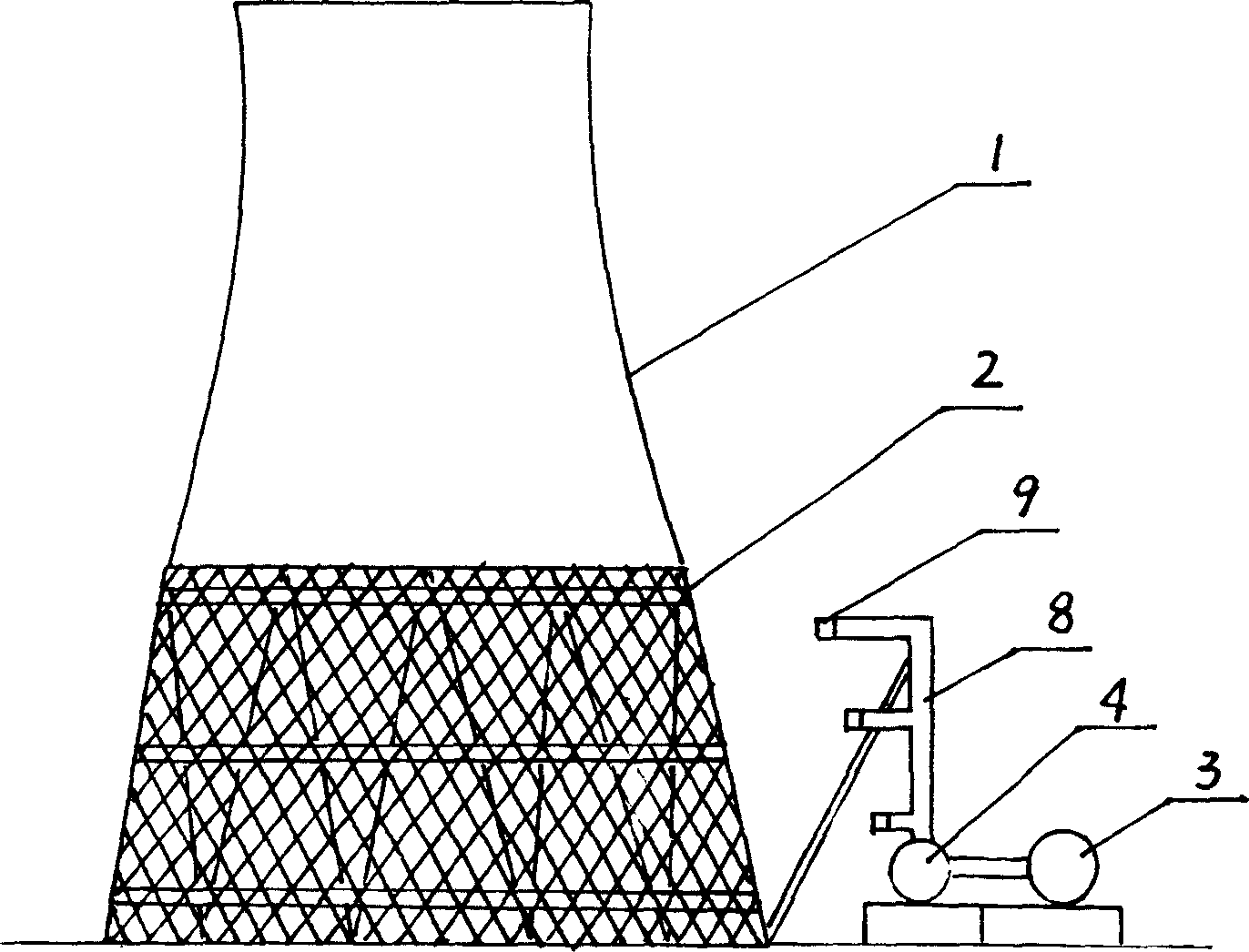

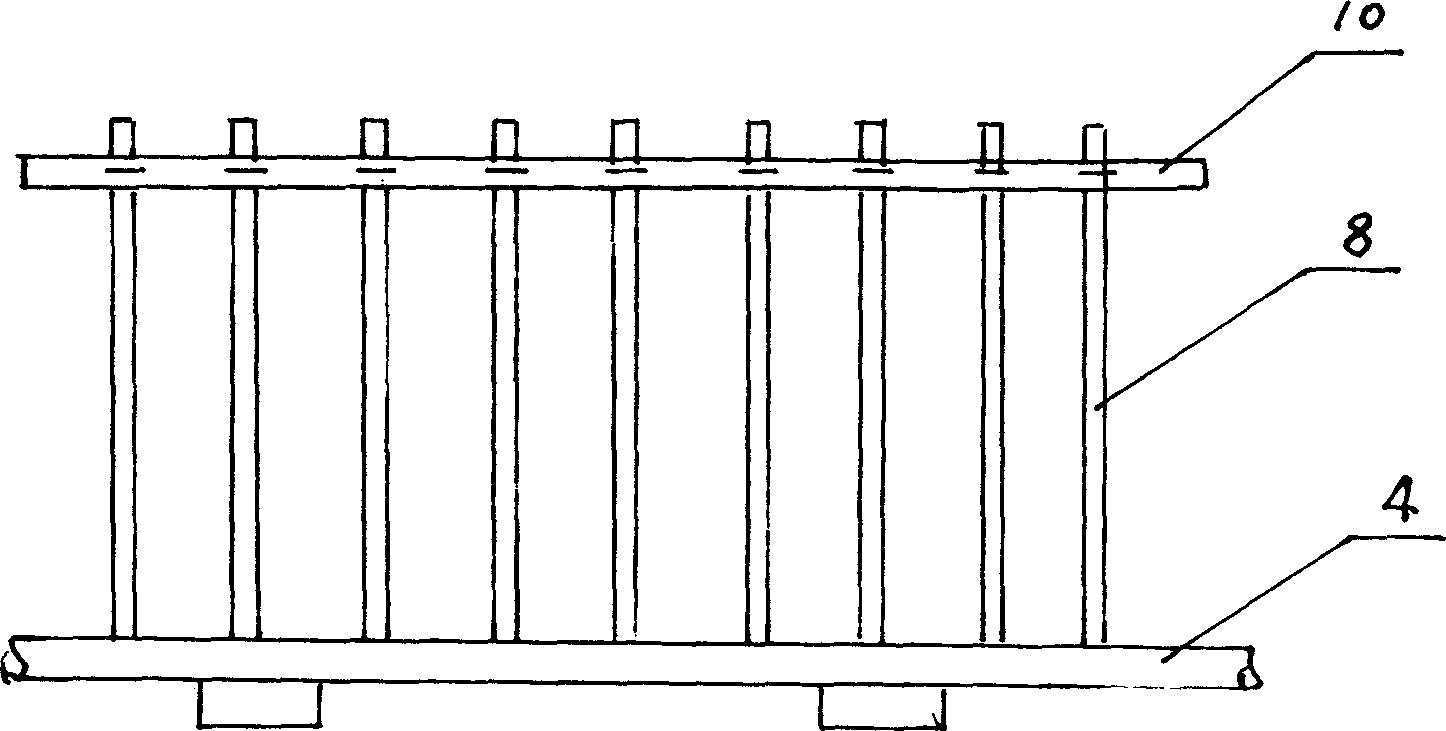

[0011] At the air inlet of the cooling tower 1, on the outside of the slanted pillar, use metal mesh 2 with a mesh size of 30×30mm to 200×200mm for enclosure. The slanted pillar and the rigid ring beam at the lower part of the tower are pasted with a plastic film that is resistant to freezing and penetration. Prevent water spray from freezing to cause harm. For the convenience of water pressure control, the inner side of the main water pipeline 3 is provided with segmented water pipes 4, and the segmented water pipes 4 are divided into four sections. 7. To supply water to the two sections of pipelines, design the number of branch water pipes 8 and water nozzles 9 according to the total area of the air inlet. Each branch water pipe 8 is connected together with a connecting plate 10 to ensure the stability of the facility. Select the size of the pipe diameter and the matching water pump 7 according to the total water flow and the required lift. The water pump 7 is located in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com