Food-trash processing unit for kitchen

A food waste treatment and kitchen technology, applied in waste treatment, sludge treatment, preliminary treatment to promote the drying of solid materials, etc., can solve the problems of large size, expensive, unsuitable for ordinary families and restaurants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

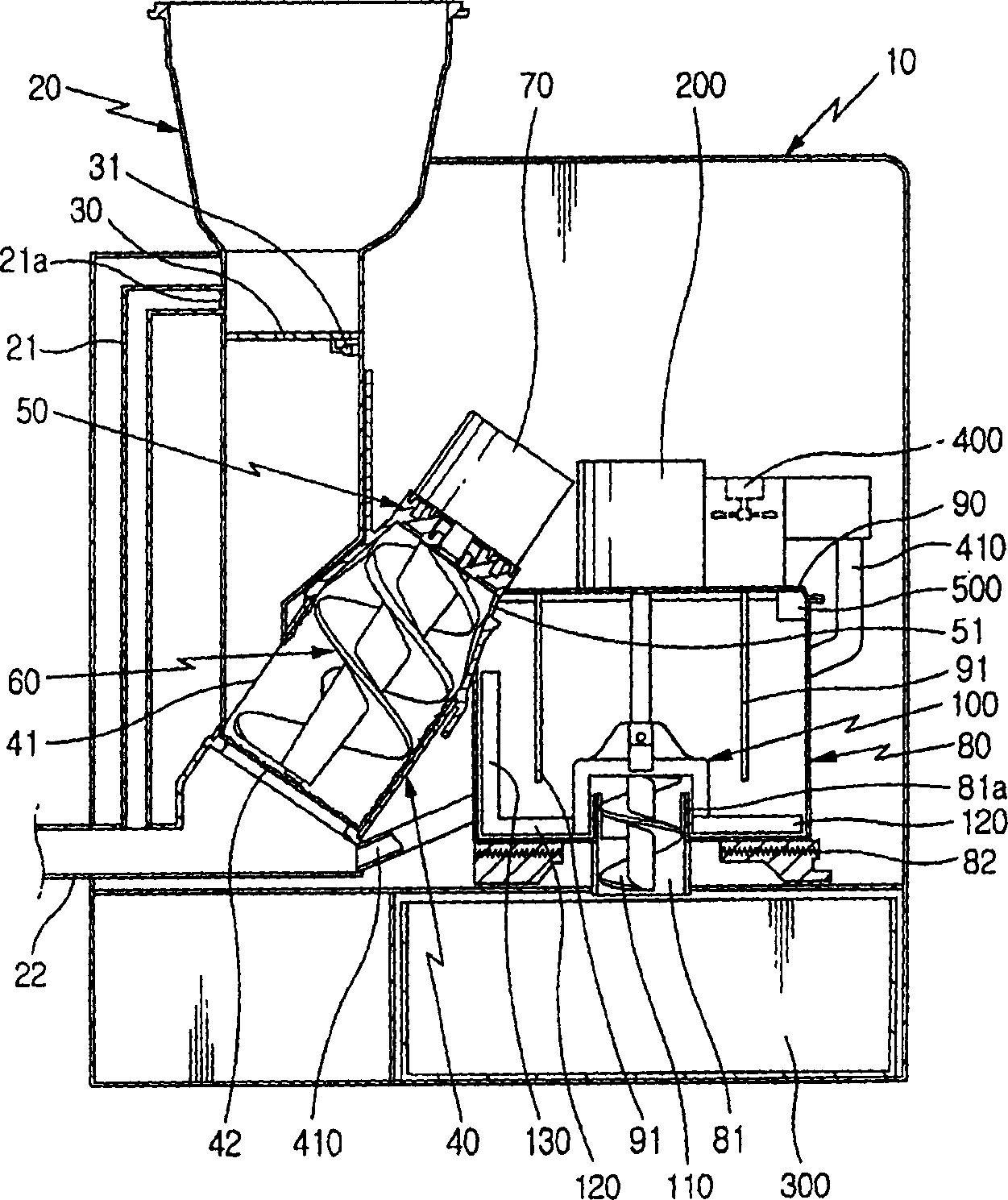

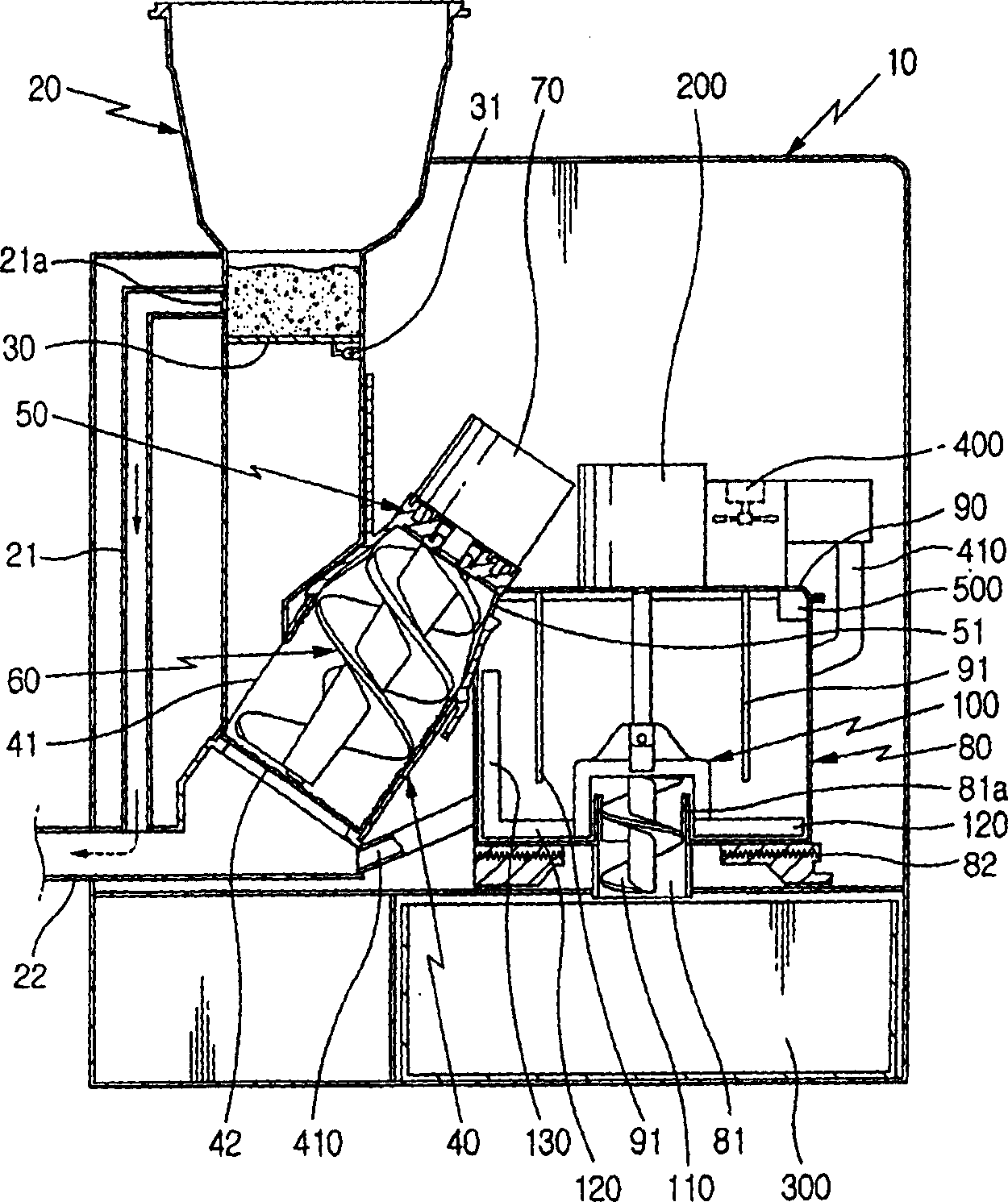

[0016] The technical structure of the present invention will be described in detail below with reference to these drawings.

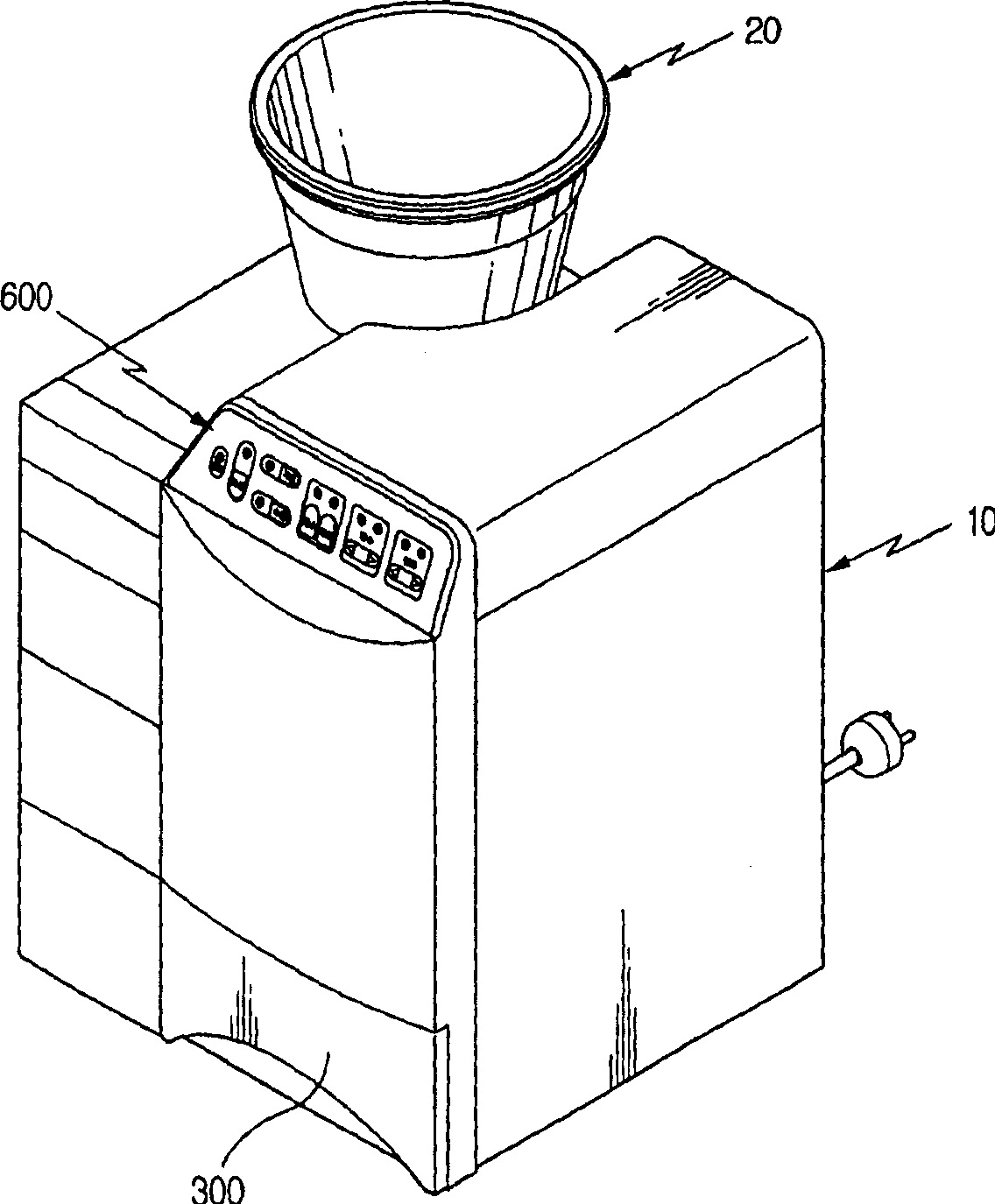

[0017] Briefly, the food waste disposal unit for kitchen according to the present invention is characterized in that, as Figures 1 to 7 As shown in , the unit comprises: a main body 10 placed in the lower space of the dish washing station; an inlet pipe 20 provided in the main body 10 in connection with the drain of the dish washing station, the inlet pipe is provided with a branch pipe 21 and a The discharge pipe 22; the closing plate 30 placed in the inlet pipe 20 which can be opened or closed automatically by the switch actuator 31; There are inlet openings 41 and filter-separation screens 42; caps 50 mounted thereon in the upper part of the dewatering drum 40, said caps being provided with a discharge opening 51; drive screws 60 supported on the caps 50, said drive screws assembling Inside the filtration-separation screen 42; the motor 70 for driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com