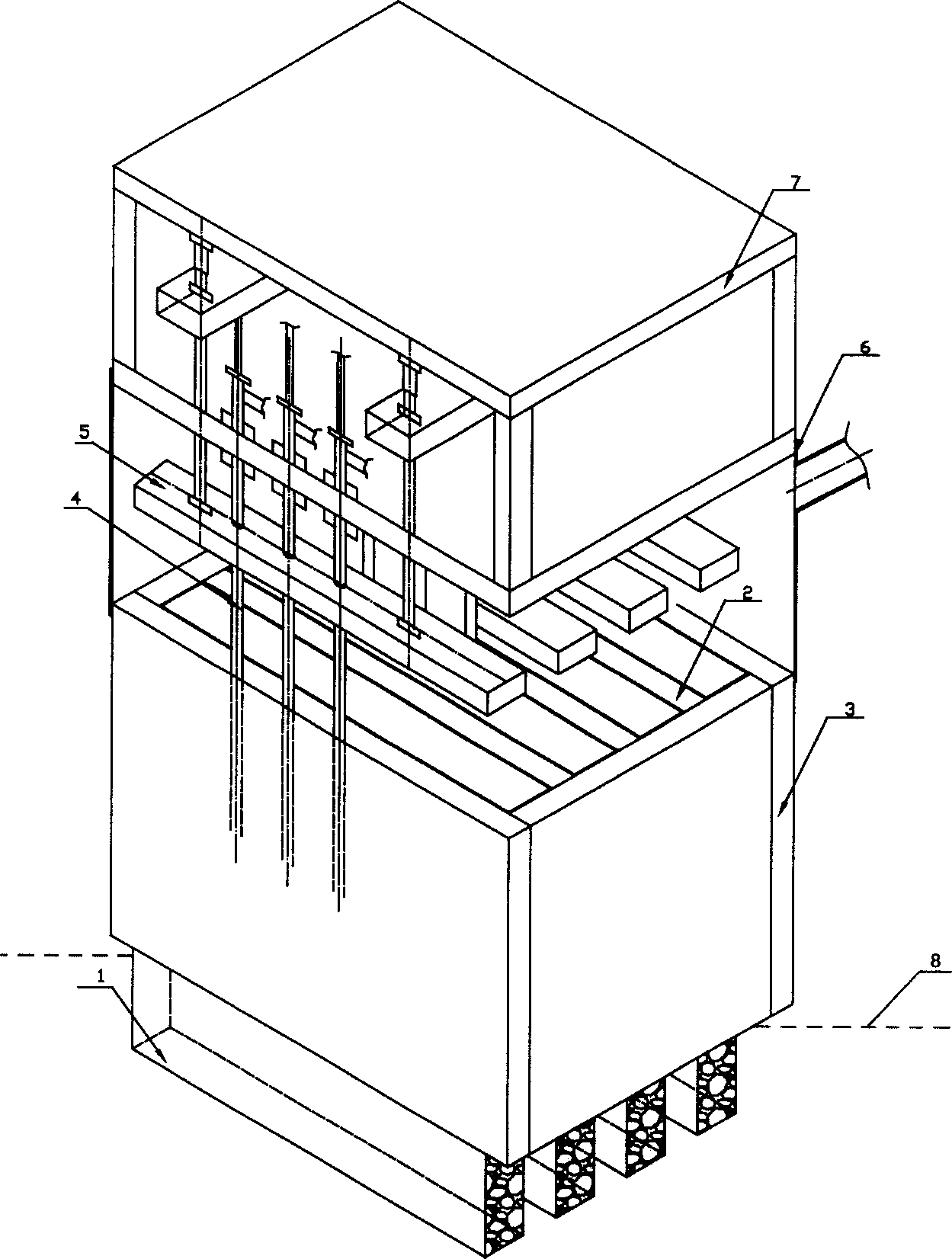

Method for industrial production of wide plate and its shaping equipment

A sheet forming and wide-width technology, which is applied to other household appliances, applications, household appliances, etc., can solve the problems of poor fluidity of mixtures, process conditions, unsuitable product shape and size deformation, and difficulty in producing wide-width sheets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

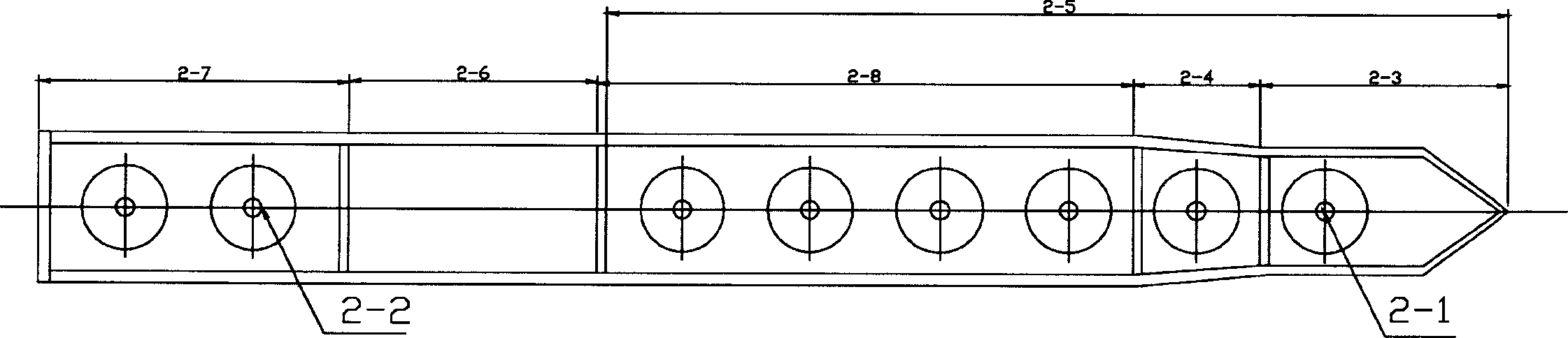

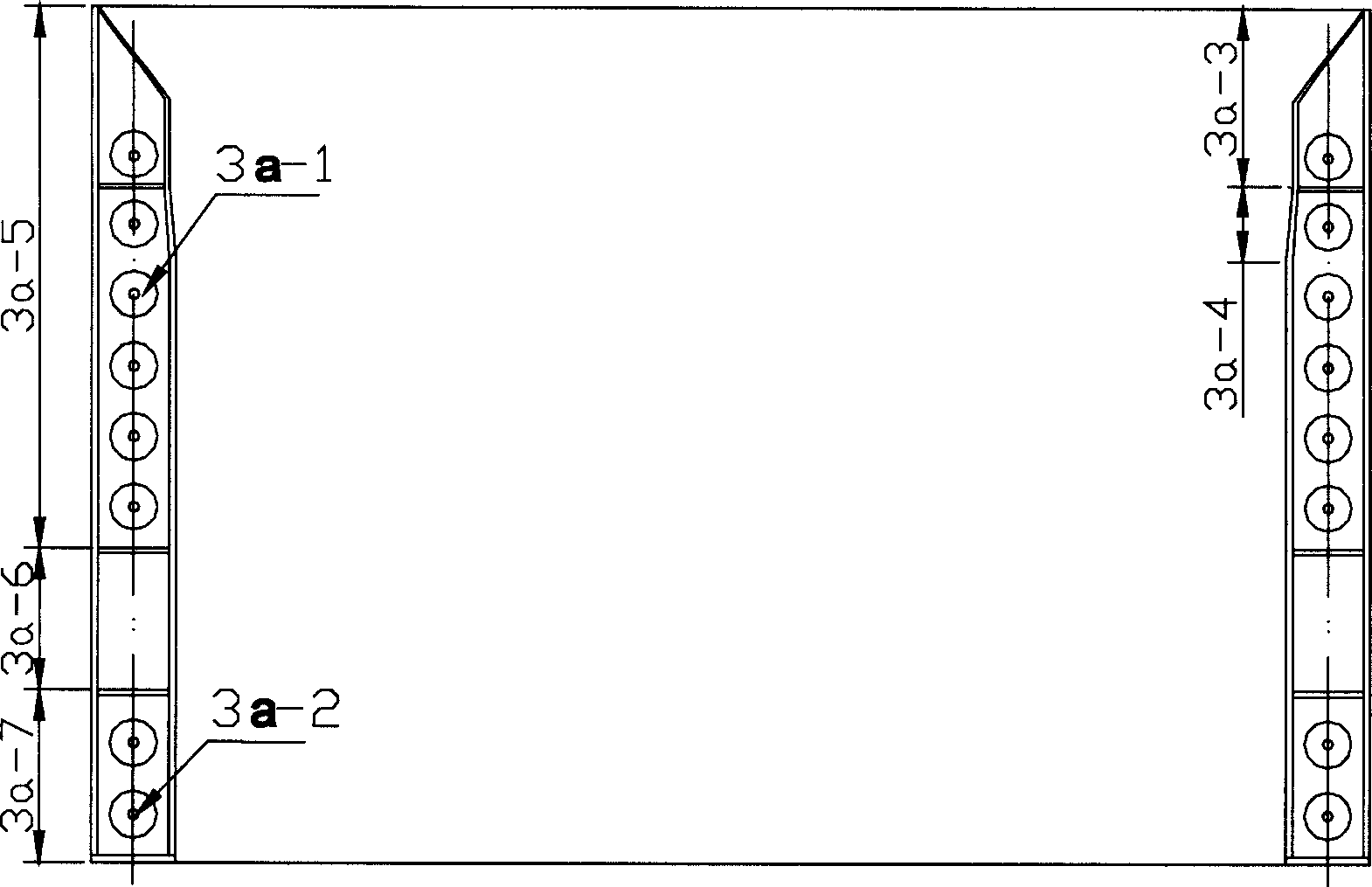

Method used

Image

Examples

Embodiment 2-3

[0045] The production steps and molding equipment of Examples 2-3 are the same as those of Example 1, except that the fibers are poplar or rice husk powder, respectively.

Embodiment 4

[0046] Embodiment 4 is the production of rubber-plastic elastomer hollow board

[0047] Mix the fine rubber powder 80 mesh with ethylene-vinyl acetate, dioctyl phthalate, and sulfur in a high-speed mixer with a spacer according to the weight of Table 2, the modification temperature is 170 ° C, the time is 7 minutes, and the mixer speed is 3000 rev / min for modification. Then add the high-density polyethylene into the oil mixer according to the weight of Table 2 and plasticize it to a molten state, then add the modified rubber powder, the mixing temperature is 170 ° C, and the time is 7 minutes, so that the added materials are completely compatible. After cooling, the rubber-plastic elastomer is pulverized as a raw material for rubber-plastic sheet molding. Then in the wide-width sheet forming equipment, the heating oil temperature is 170°C, the pressure is 30Mpa, and the finished product speed is m / 9 minutes to form a 1000mm rubber-plastic elastomer hollow sheet, and then the ...

Embodiment 5

[0048] Embodiment 5 is fiber hollow board

[0049] The components and weights of the materials listed in Table 3 are fully mixed in the mixer, and the fiber hollow board is formed according to the process parameters listed in Table 3 in the wide-width sheet forming equipment, and the finished fiber hollow board is obtained after finishing and testing.

[0050] Example formula

[0051] Example 4

[0052] Example formula

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com