Objective lens holder for an objective lens driving device

A technology of a driving device and an objective lens holder, which is applied in the field of objective lens holder, can solve the problems of high cost, reduced sensitivity, deterioration of inclination angle characteristics, etc., and achieves the effects of convenient assembly and thinning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

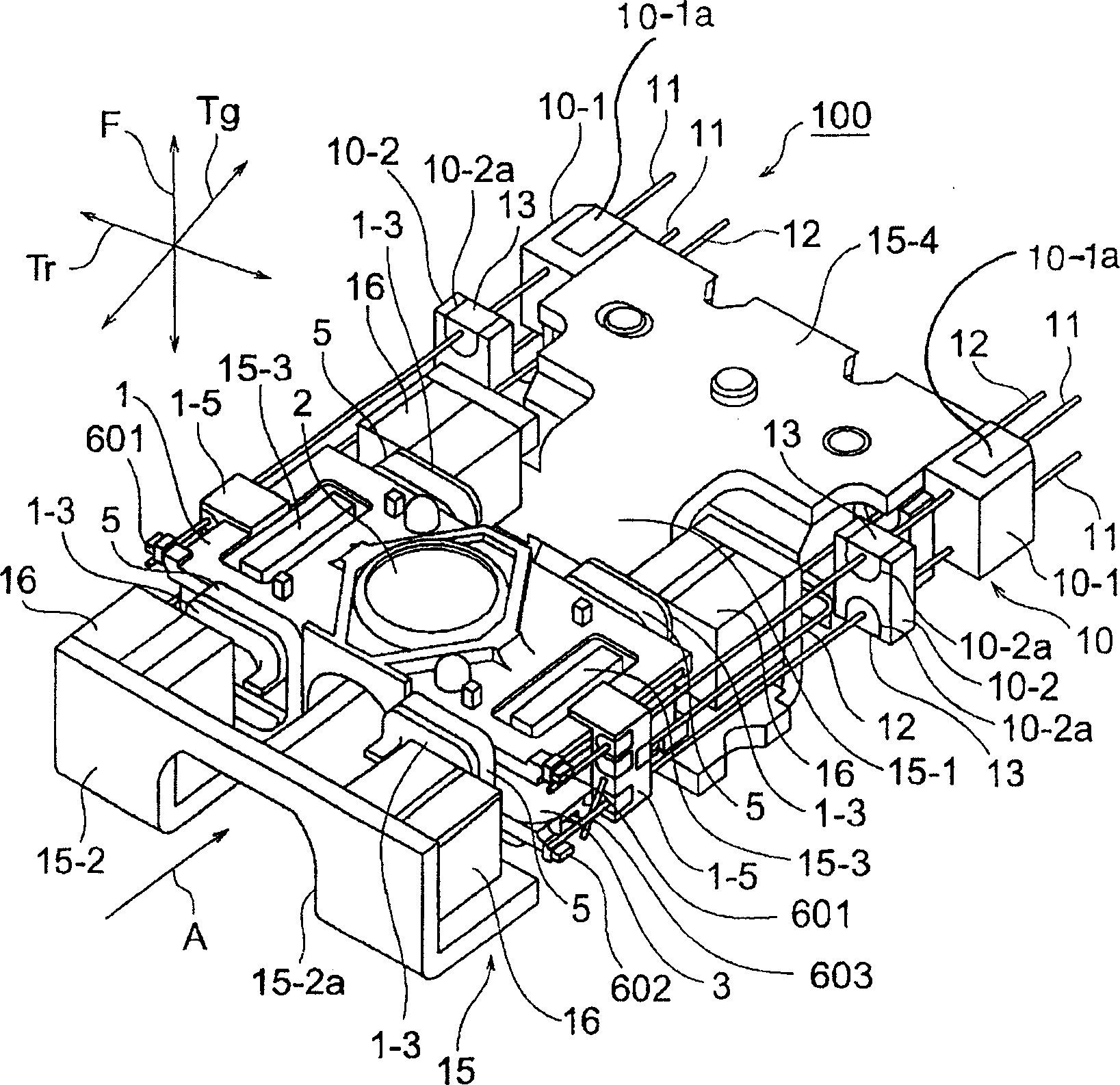

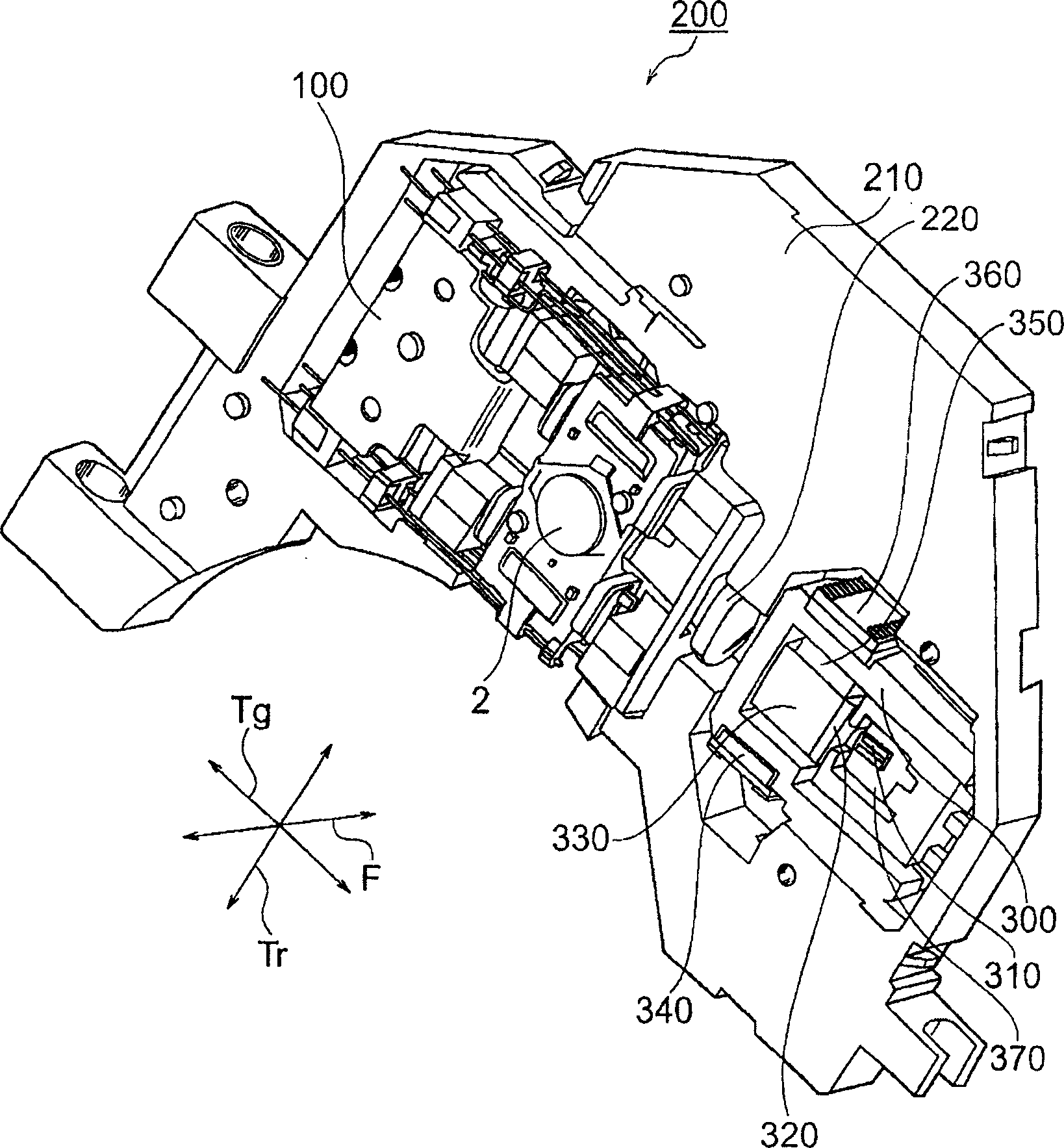

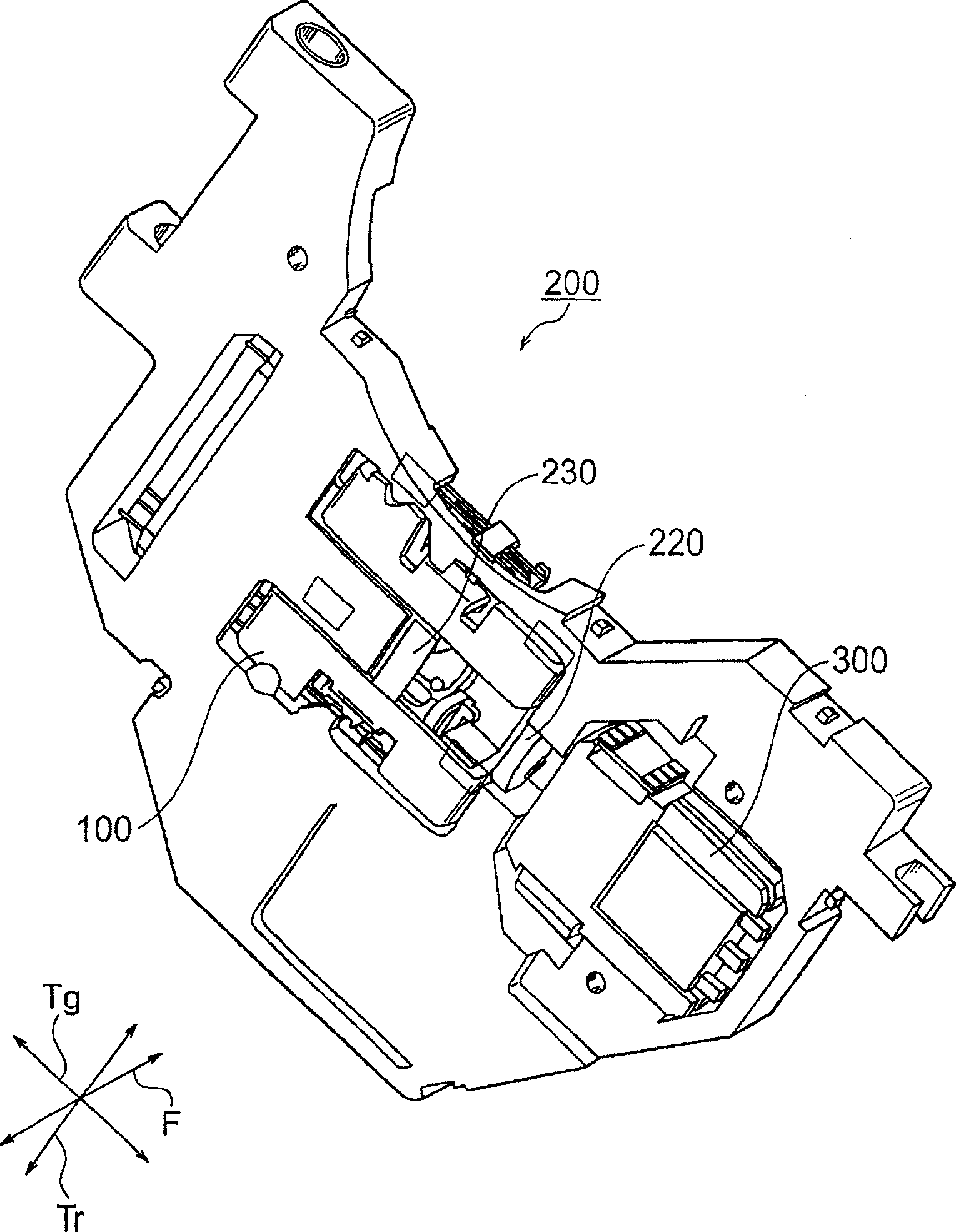

[0035] figure 1 It is a perspective view of an objective lens driving device 100 according to an embodiment of the present invention, showing a state in which a metal top cover (not shown) is removed.

[0036] Such as figure 1 As shown, the objective lens driving device 100 has an objective lens holder 1 . The objective lens holder 1 has a lens mounting portion (described later) formed of a through hole for mounting the objective lens 2 at a central position. On both sides of the lens mounting portion of the objective lens holder 1 in the tracking direction Tr, a pair of main winding frame portions (to be described later) for winding a tilt coil and a focus coil 3 to be described later are provided.

[0037] This main winding frame part is made open, so that the opening above it can expose a part of the yoke (to be described later). Among the four outer wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com