Multi-axis robot provided with a control system

A multi-axis robot and control system technology, applied in general control systems, control/regulation systems, program-controlled manipulators, etc., can solve complex problems, long working hours, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

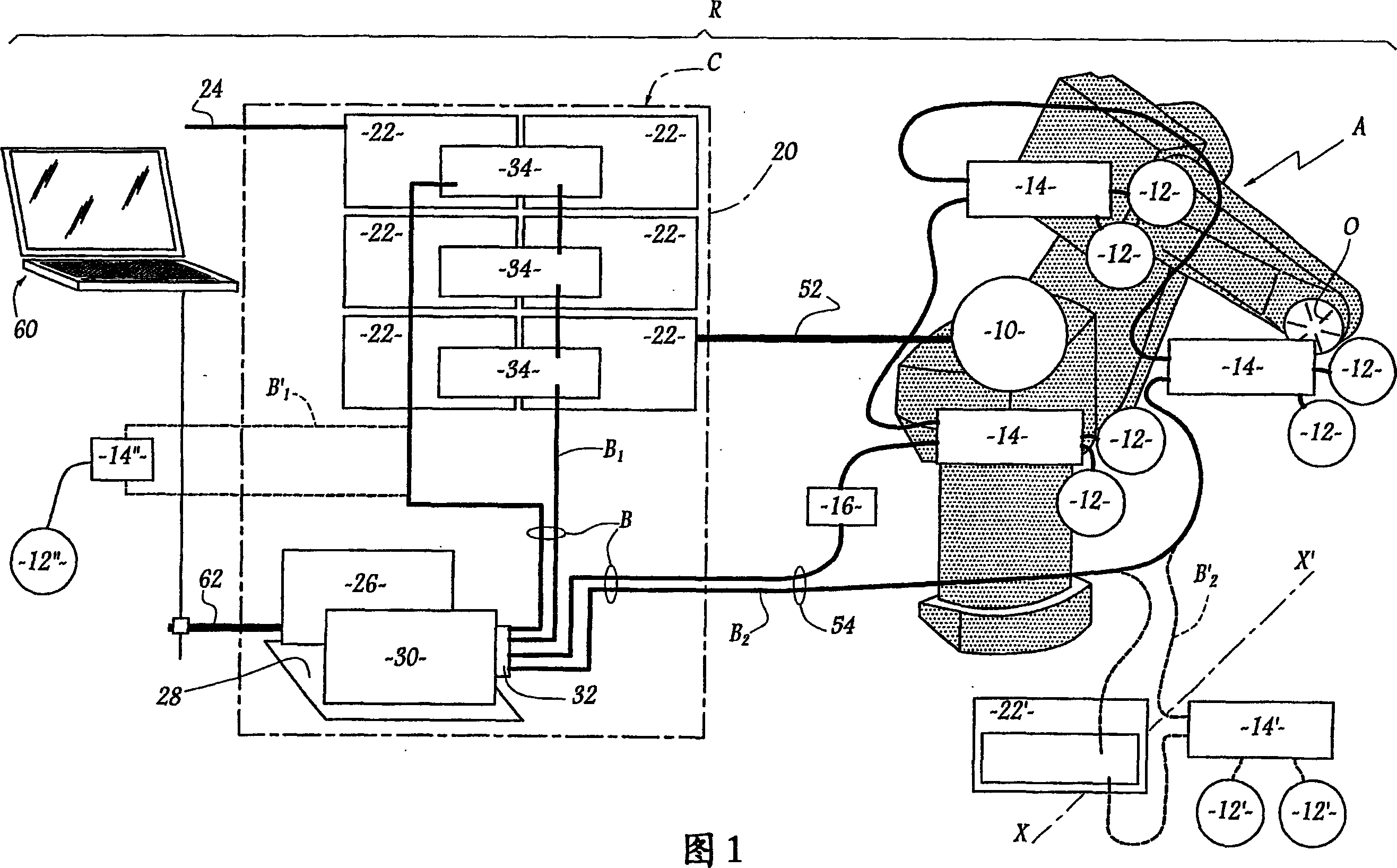

[0017] Through the following description of the embodiment of the multi-axis robot and its control system according to the invention, people can better understand the present invention and have a clearer understanding of other advantages. This embodiment is only given by way of example with reference to the accompanying drawings , where the simple graph is a theoretical rough representation of the associated control system and multi-axis robot.

[0018] The robot arm A of the robot R shown in the figure is arranged along the conveying path shown in the direction X-X'. The robotic arm is equipped with six motors, each of which moves the moving part of the robotic arm about one of the six axes of the robotic arm to move the tool O to a designated position. These electric motors are represented in the figure as mechanization 10 . In fact, they are distributed in the robot arm A. Distributed throughout the robot R are six analog position sensors or encoders 12 for measuring the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com