Aqueous polyurethane cement composition

A technology of water-based polyurethane and composition, which is applied in the field of water-based polyurethane mortar composition, which can solve the problems of reduced material strength or surface strength, easy damage to the surface of the coating film, etc., and achieves no warping, easy coating construction, and heat resistance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

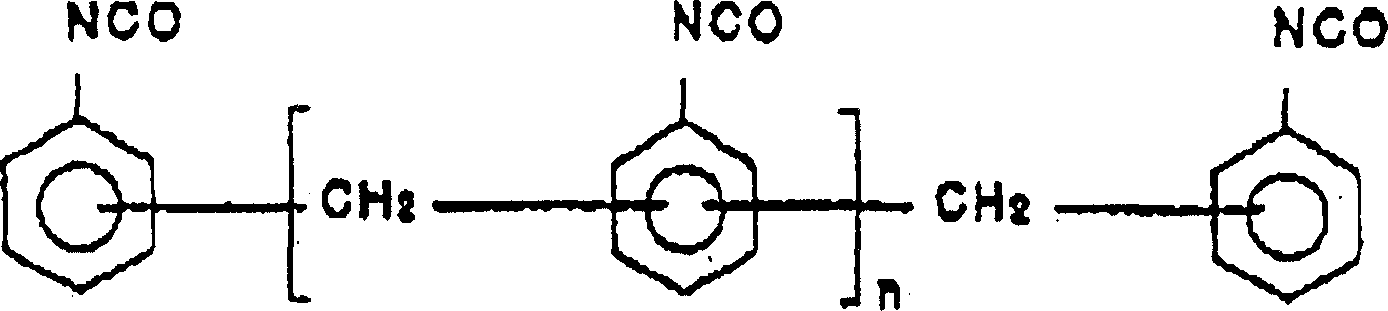

Method used

Image

Examples

Embodiment 1

[0032]As the main ingredient, 73 parts of water-dispersible polyester polyol (Sumika Bioel: VPLS2248) and 12 parts of polyester polyol {Kyowa Hakko Co., Ltd.: Kiyoichiwa Boll 2000BA}, 5 parts of toner, 10 parts polysiloxane defoamer. As a curing agent, mix 75 parts of WC-103 and 25 parts of MB-5S. Moreover, 400 parts of aggregates containing the hydraulic mortar of the compounding example 1 of Table 1 were mix|blended, and the water-based polyurethane mortar composition of Example 1 was manufactured.

Embodiment 2

[0034] As the main ingredient, 90 parts of water-dispersible polyester polyol (Sumika Bioel: VPLS2248) and 5 parts of polyester polyol {Kyowa Hakko Co., Ltd. Kiyoichiwa Boll 2000BA}, 5 parts of toner, 10 part polysiloxane defoamer. As a curing agent, mix 100 parts of MR-200. Moreover, 950 parts of aggregates containing the hydraulic mortar of the compounding example 2 of Table 1 were mix|blended, and the water-based polyurethane mortar composition of Example 2 was manufactured.

Embodiment 3

[0036] In the combination of Example 2, only 100 parts of VPLS2248 was used for changing the main ingredient, and 50 parts of DRC3476 and 50 parts of WC-103 were used as curing agent. Moreover, 950 parts of aggregates containing the hydraulic mortar of the compounding example 2 of Table 1 were mix|blended, and the water-based polyurethane mortar composition of Example 3 was manufactured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com